Preparation method and application of small peptide chelated zinc compound

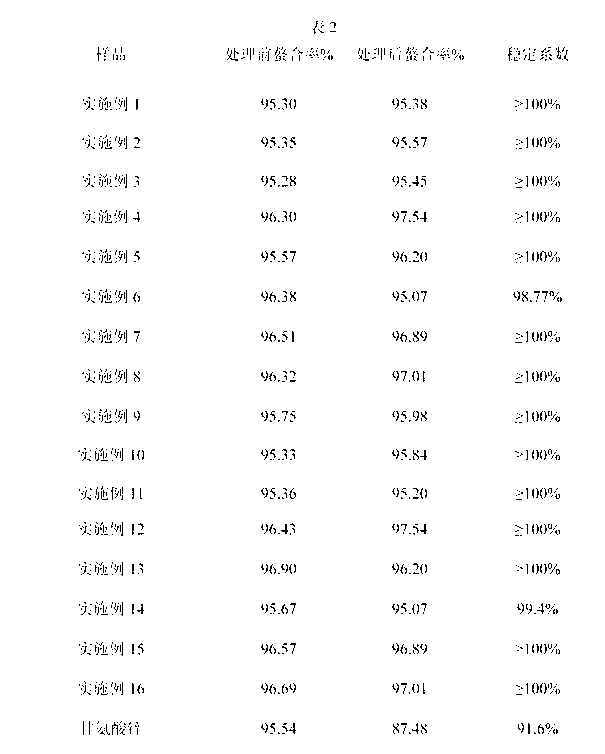

A small peptide chelation and complex technology, applied in microorganism-based methods, biochemical equipment and methods, applications, etc., can solve problems such as stability problems that are not well solved, achieve high chelation rate, improve immunity Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] The preparation method 1 of small peptide complex comprises the following steps:

[0088] 1) Preparation of culture medium: 100kg soybean meal with a crude protein content of 46%, 100kg rice protein powder with a crude protein content of 60%, 100kg soybean protein concentrate with a crude protein content of 65%, 6kg sucrose, and dilute to 1000L with water , adjust the pH value of the reaction solution to 6.8 with hydrochloric acid or sodium hydroxide, and sterilize at 121°C for 18 minutes;

[0089] 2) Preparation of small peptide fermentation broth: put the Bacillus licheniformis strain cultured in a 32°C constant temperature shaker at 200r / min for 24h into the above-mentioned sterilized 1000L culture broth to make the concentration of bacteria in the culture broth About 5×10 7 cfu / ml, after culturing at 30°C for 24 hours, add hydrochloric acid or sodium hydroxide to adjust the pH of the medium to 7.0, add 3kg of neutral protease (500U / g protein material), and continue...

Embodiment 2

[0094] The preparation method 2 of small peptide complex comprises the following steps:

[0095] 1) Preparation of culture medium: 100kg of soybean meal with a crude protein content of 46%, 100kg of rice protein powder with a crude protein content of 60%, 100kg of soybean protein concentrate with a crude protein content of 65%, 3kg of sucrose, 3kg of glucose, and 2kg of starch , adjust the volume to 1000L with water, adjust the pH value of the reaction solution to 6.8 with hydrochloric acid or sodium hydroxide, and sterilize at 121°C for 18 minutes;

[0096] 2) Preparation of small peptide fermentation broth: put the Bacillus subtilis strain cultured in a 32°C constant temperature shaker at 200r / min for 24 hours into the above-mentioned sterilized 1000L culture broth to make the concentration of bacteria in the culture broth About 5×10 7 cfu / ml, after culturing at 30°C for 24 hours, add hydrochloric acid or sodium hydroxide to adjust the pH of the medium to 6.8, add 2.4kg of ...

Embodiment 3

[0101] The preparation method 3 of small peptide complex comprises the following steps:

[0102] 1) Preparation of culture medium: 100kg of soybean meal with a crude protein content of 46%, 100kg of rice protein powder with a crude protein content of 60%, 100kg of soybean protein concentrate with a crude protein content of 65%, 8kg of glucose, and dilute to 1000L with water , adjust the pH value of the reaction solution to 6.8 with hydrochloric acid or sodium hydroxide, and sterilize at 121°C for 18 minutes;

[0103] 2) Preparation of small peptide fermentation broth: Bacillus natto ( Bacillus natto ) strain solution into the above-mentioned sterilized 1000L culture solution, so that the concentration of bacteria in the culture solution is about 5×10 7 cfu, after culturing at 32°C for 24 hours, add hydrochloric acid or sodium hydroxide to adjust the pH of the medium to 6.8, add 3.6kg of neutral protease (600U / g protein raw material), and continue enzymatic hydrolysis at 43°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com