Lithium ion battery anode material and preparation method of same, and lithium ion battery

A technology for lithium ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstable crystal structure of materials, affecting material cycle performance, affecting material crystal growth, etc., and improving electrochemical performance. , good cycle performance, improve the effect of electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a preparation method of the lithium ion battery cathode material described in the above technical solution, comprising the following steps:

[0048] A) Mix lithium-containing compounds, manganese-containing compounds, M-containing compounds, titanium-containing compounds, phosphorus-containing compounds and carbon-containing compounds, and ball mill them to obtain a slurry. The M is Ti, Co, Fe, Mg, Al, Cr, One or more of Nb;

[0049] B) calcining the slurry to obtain a positive electrode material for a lithium ion battery.

[0050] In the present invention, firstly, lithium-containing compounds, manganese-containing compounds, M-containing compounds, titanium-containing compounds, phosphorus-containing compounds and carbon-containing compounds are mixed with carbon-containing compounds to obtain a mixture, wherein M is Ti, Co, Fe, Mg, One or more of Al, Cr, Nb, more preferably one of Ti, Co, Fe, Mg, Al, Cr, Nb, most preferably Fe or ...

Embodiment 1

[0067] Weigh 46.156g of lithium hydroxide, 78.246g of manganese dioxide, 7.98g of ferric oxide, 15.97g of titanium dioxide, 171.678g of diammonium hydrogen phosphate and 64g of glucose, and disperse the above raw materials in 0.715kg of deionized water to form a solid The suspension with a content of 35% is ball milled for 10 hours. After the ball milling, the slurry is spray-dried, and the dry powder is calcined at a high temperature under the protection of nitrogen. The calcination temperature is 700°C and the calcination time is 9 hours. , and pulverize the calcined product to obtain the positive electrode material of the lithium ion battery.

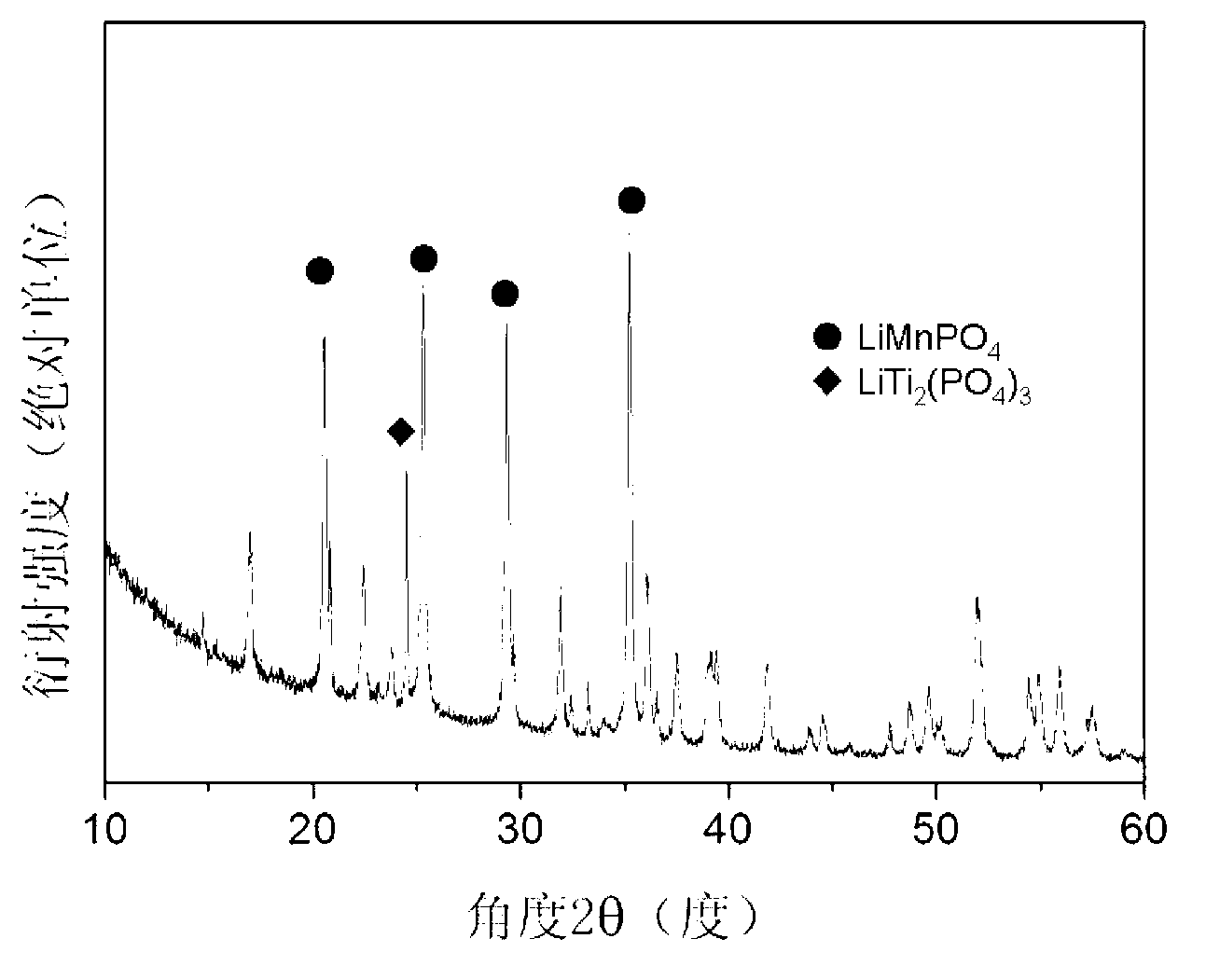

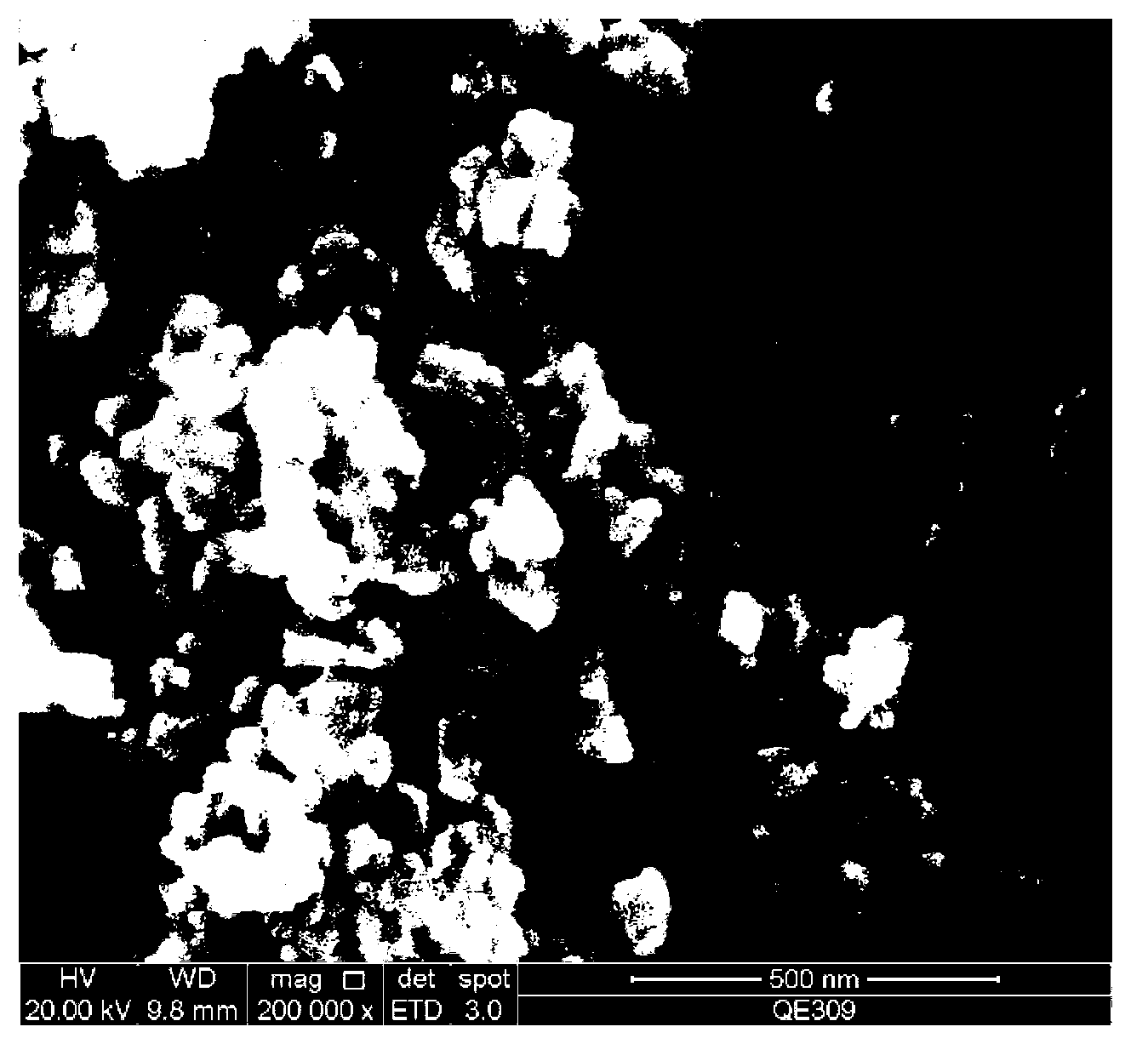

[0068] Adopt Japan Shimadzu XRD-6000 type X-ray powder diffractometer (XRD) to characterize the positive electrode material of lithium ion battery prepared in embodiment 1, the result is as follows figure 1 as shown, figure 1 It is the XRD spectrogram of the lithium ion battery cathode material prepared in Example 1 of the present i...

Embodiment 2

[0077] Weigh 79.188g of lithium acetate, 114.95g of manganese carbonate, 160.856g of titanium sulfate, 325.008g of ammonium phosphate and 204g of phenolic resin, and disperse the above-mentioned raw materials in 0.884kg of deionized water to form a suspension with a solid content of 50%. Ball milling, the ball milling time is 15 hours, after the ball milling, the slurry is spray-dried, and the dry powder is calcined at a high temperature under the protection of nitrogen atmosphere, the calcining temperature is 800°C, the calcining time is 16 hours, and the calcined product is pulverized to obtain lithium ions battery cathode material.

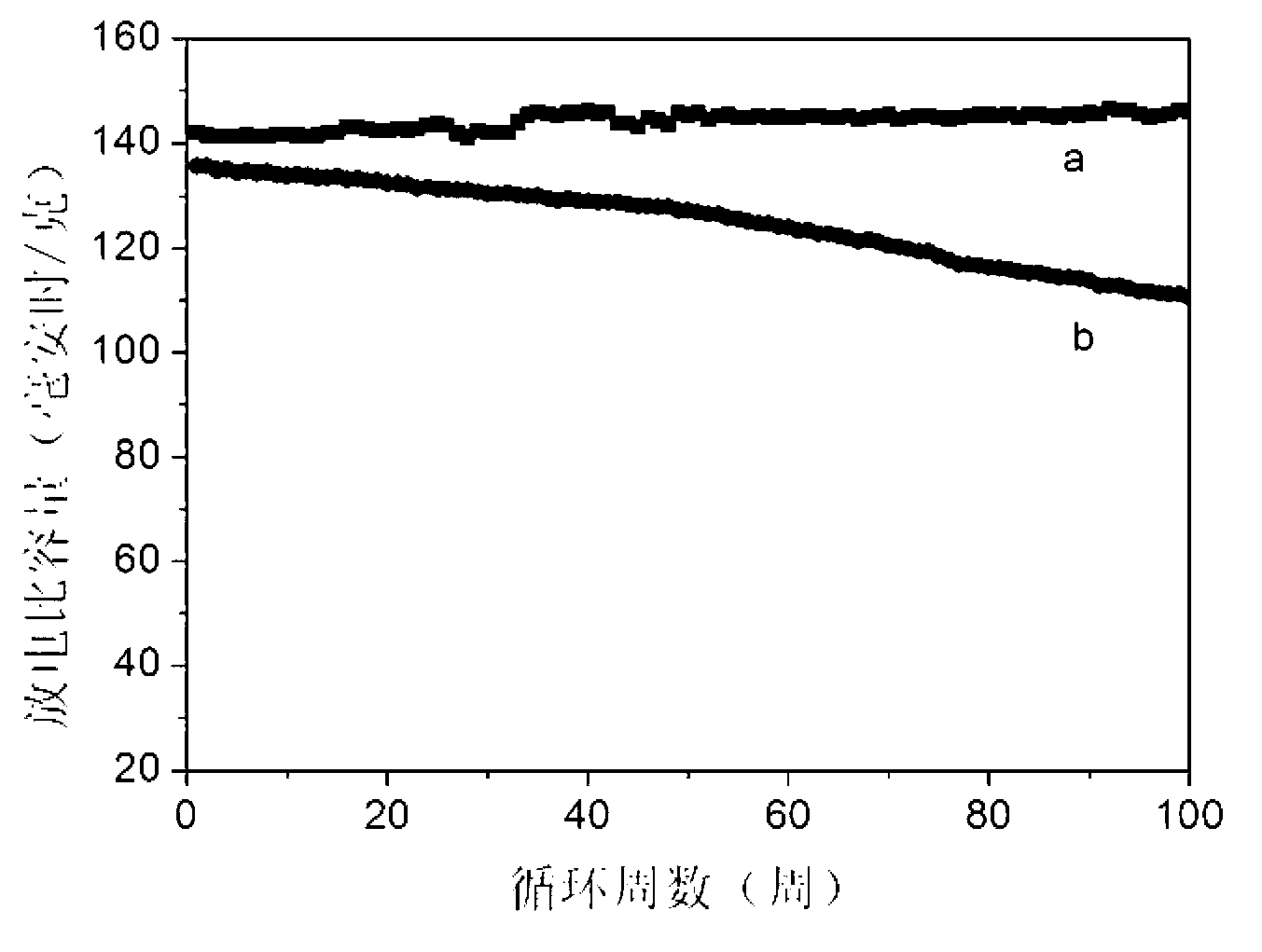

[0078] Mix the positive electrode material prepared in Example 2 with acetylene black conductive agent and polyvinylidene fluoride binder in a mass ratio of 90:5:5, apply it on the aluminum foil current collector, dry it at 80°C and use a punching machine to make it The electrode sheet with a diameter of 1cm, the lithium sheet is the negative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com