Zymomonas mobilis gene engineering bacterium capable of producing isobutanol and construction method of zymomonas mobilis gene engineering bacteria

A technology of Zymomonas and genetically engineered bacteria, applied in the field of genetically engineered bacteria producing isobutanol and its construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

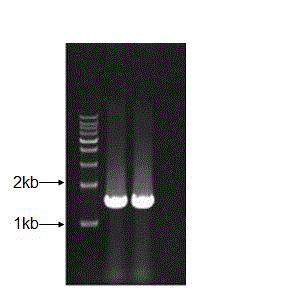

[0036] Example 1 Amplification of 2-ketoisovalerate decarboxylase and alcohol dehydrogenase genes

[0037] (1) Culture of Lactococcus lactis and preparation of total DNA

[0038] Lactococcus lactis in MRS medium (peptone 10g / L, beef extract powder 10g / L, yeast powder 5g / L, glucose 20g / L, dipotassium hydrogen phosphate 2g / L, diamine hydrogen citrate 2g / L, sodium acetate 5g / L, magnesium sulfate 0.58g / L, manganese sulfate 0.25g / L, Tween 80 1mL / L, pH7.0) at 30°C for static culture to the logarithmic phase, and then use the genome extraction kit to extract the total DNA.

[0039] (2) Amplification of 2-ketoisovalerate decarboxylase gene

[0040] The genome of Lactococcus lactis was extracted, and the primers were designed as follows according to the gene sequence of Lactococcus lactis 2-ketoisovalerate decarboxylase reported in GenBank:

[0041] Upstream primer k1: 5'-C GAGCTC AATAAAATATGGAGGAATGCGATG-3' restriction site is Sac I;

[0042] Downstream primer k2: 5'-CGC ...

Embodiment 2

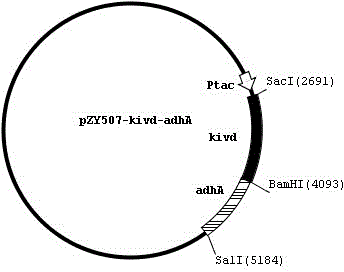

[0077] Example 2. Construction of recombinant plasmids

[0078] (1) Preparation of expression vector

[0079] In LB medium (10 g / L sodium chloride, 10 g / L peptone, 10 g / L yeast powder, pH 7.5) containing chloramphenicol (100 μg / mL), inoculate Escherichia coli DH5α carrying plasmid pZY507 at 37 Cultivate overnight at 200r / min. Extract the plasmid with a plasmid extraction universal kit.

[0080] (2) Construction of pZY507K recombinant plasmid

[0081] For vectors pZY507 and pMD19- kivd Use separately Sac I and Bam HI was subjected to double enzyme digestion, followed by agarose gel electrophoresis, and the required DNA fragments were recovered by gel cutting and ligated with T4 ligase. The double enzyme digestion system was:

[0082] Plasmid 20 μL

[0083] Sac I 1 μL

[0084] Bam HI 1μL

[0085] 10×Buffer 5μL

[0086] dd H 2 O 23 μL

[0087] Total volume 50μL

[0088] Reaction at 37℃ for 1h

[0089] The above restriction fragments were purified using a DN...

Embodiment 3

[0101] Example 3. Construction of genetically engineered strains

[0102] Preparation of Competent Zymomonas mobilis:

[0103] (1) Pick a single colony from a freshly cultured agar plate and inoculate it in 10 mL of T medium (glucose 20 g / L, yeast powder 10 g / L, ammonium sulfate 1 g / L, dipotassium hydrogen phosphate 1 g / L, magnesium sulfate 0.5g / L, pH6.5), cultured overnight at 30°C.

[0104] (2) Transfer the above culture into 500mL T liquid culture medium according to the inoculum amount of 1%, and culture it statically at 30°C.

[0105] (3) When the OD of the culture 600 When the temperature reaches 0.36, the culture is stopped, and the culture is quickly placed in an ice bath for 15-30 minutes to rapidly cool the culture.

[0106] (4) Transfer the bacterial solution to an ice-cold centrifuge tube, centrifuge at 5000r / min at 4°C for 10 minutes, recover the cells, discard the supernatant, and wash the pellet three times with 10 mL of ice-cold sterile 10% glycerol.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com