Method for preparing granular organic compound fertilizer by using biogas slurry sludge in pig farm

A granular and compound fertilizer technology, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems that it is difficult to digest biogas slurry and sludge from pig farms, and enterprises cannot bear it, so as to achieve high application value and market prospect, and improve utilization The effect of high efficiency and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

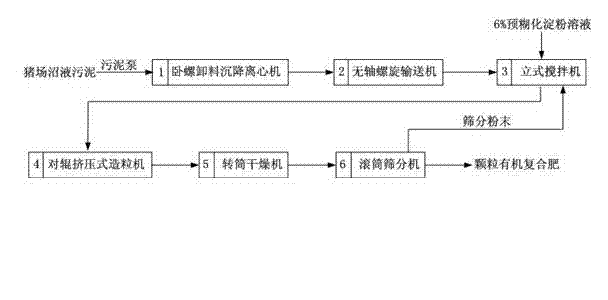

Image

Examples

Embodiment 1

[0014] Pig farm biogas sludge with a mass of 300kg and a moisture content of 70% is transported by a sludge pump to the decanter discharge sedimentation centrifuge 1, and the rotation speed of the decanter discharge sedimentation centrifuge 1 is 1100 r / min , the centrifugation time is 15min, the water content of the obtained mud cake is 40%, and the separated centrifugate enters the sewage treatment facility. The mud cake after centrifugal dehydration enters in the vertical mixer 3 through the shaftless screw conveyor 2, the rotating speed of the vertical mixer 3 is 30r / min, the mixing time is 5min, and 2.7kg mass fraction is 6% pregelatinized starch added at the same time solution. The dirt cake after stirring, mixing and forming enters the roller extrusion granulator 4 for extrusion granulation, the rotating speed of the roller extrusion granulator 4 is 16r / min, and the prepared particle size is 3-5mm. Granular organic compound fertilizer wet material. Then the wet materia...

Embodiment 2

[0016] Pig farm biogas sludge with a mass of 500kg and a moisture content of 75% is transported by a sludge pump to the decanter discharge sedimentation centrifuge 1, and the rotation speed of the decanter discharge sedimentation centrifuge 1 is 1200 r / min , the centrifugation time is 12min, the moisture content of the obtained mud cake is 42%, and the separated centrifugate enters the sewage treatment facility. The mud cake after centrifugal dehydration enters the vertical mixer 3 through the shaftless screw conveyor 2. The rotating speed of the vertical mixer 3 is 35r / min, and the stirring time is 6min. solution. The dirt cake after stirring, mixing and forming enters the roller extrusion granulator 4 for extrusion granulation, the rotating speed of the roller extrusion granulator 4 is 16r / min, and the prepared particle size is 3-5mm. Granular organic compound fertilizer wet material. Then the wet material enters the drum dryer 5, the rotating speed of the drum dryer 5 is ...

Embodiment 3

[0018] Pig farm biogas sludge with a mass of 700kg and a moisture content of 80% is transported by a sludge pump to the decanter discharge sedimentation centrifuge 1, and the rotation speed of the decanter discharge sedimentation centrifuge 1 is 1300 r / min , the centrifugation time is 14min, the moisture content of the obtained mud cake is 44%, and the separated centrifugate enters the sewage treatment facility. The mud cake after centrifugal dehydration enters in the vertical mixer 3 through the shaftless screw conveyor 2, the rotating speed of the vertical mixer 3 is 40r / min, and the mixing time is 7min, and 4.2kg mass fraction is 6% pregelatinized starch added at the same time solution. The dirt cake after stirring, mixing and forming enters the roller extrusion granulator 4 for extrusion granulation, the rotating speed of the roller extrusion granulator 4 is 16r / min, and the prepared particle size is 3-5mm. Granular organic compound fertilizer wet material. Then the wet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com