Erythromycin A oxime clean synthetic method and specially-combined reaction equipment for same

A reaction device, a technology of erythromycin oxime thiocyanate, which is applied in the field of drug intermediate synthesis, can solve the problems of adverse gastrointestinal irritation, unfavorable drug popularization and application, low oral bioavailability, etc., and is easy to achieve system pressure. Control, fractional distillation effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

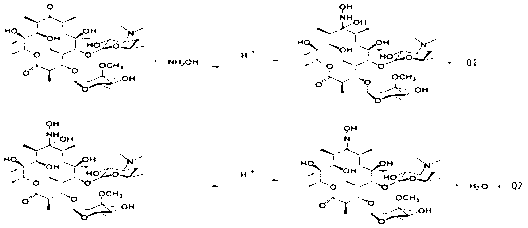

Problems solved by technology

Method used

Image

Examples

Embodiment 1

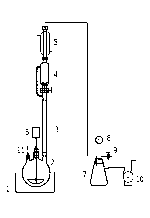

[0026] Embodiment 1: earlier at room temperature and normal pressure, a 200g absolute ethanol is dropped into a 1000ml four-necked flask, add 98% hydroxylamine hydrochloride 36g and 96% sodium hydroxide 15.8g, stir and dissolve, and have solid sodium chloride to generate, Then add 100g of 84% erythromycin thiocyanate, stir to dissolve, then add 40g of dichloroethane, install a vertical thorn for retention, and install a constant pressure separating funnel on the separation funnel. The bottom is made of a sand core to make a waterproof layer (under natural gravity, low-viscosity organic solvents can pass through, but water will not pass through), a condenser is installed on the constant-pressure separating funnel, and the water bath is heated to 50-55 degrees Celsius. The boiling point of methane is low, and the outlet pressure of the system is set to normal pressure. Dichloromethane vaporizes and evaporates with water. After condensation, it separates layers in the constant pre...

Embodiment 2

[0028] Embodiment 2: the 250g oxime salt mother liquor that obtains in example 1 joins 1000ml four-neck flask after analysis, adds dehydrated alcohol 29g, 98% hydroxylamine hydrochloride 11.1g and 96% sodium hydroxide 6.6g, stirs and dissolves, And a small amount of solid sodium chloride is formed, then add 100g of 84% erythromycin thiocyanate, stir to dissolve, then add 20g of dichloroethane, install vertical thorns to retain, and divide to retain a constant pressure Separating funnel, the bottom of the constant pressure separating funnel is made of sand core to make a waterproof layer (under natural gravity, low-viscosity organic solvents can pass through, and water will not pass through), a condenser is installed on the constant pressure separating funnel, and the water bath is heated When the temperature reaches 50-55 degrees Celsius, dichloromethane vaporizes and evaporates with water, and after condensation, it is stratified in the constant pressure separatory funnel. In...

Embodiment 3

[0030] Example 3: Adding raw materials Referring to Example 2, the operation process was the same as in Example 2, and the red oxime filter cake was obtained with a weight of 82 g, a purity of 93.5%, and a total yield of 96.6%.

[0031] The above processes are three specific synthetic examples of this synthetic method including the application of the mother liquor. Industrial production can design operating procedures based on the guiding principles of this process, make industrialized equipment with the same effect, and can realize the production of erythromycin A oxime with the same effect. Clean production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com