Microbial coating agent for preparing microbial compound fertilizer and preparation method thereof

A microbial coating and compound fertilizer technology, which is applied in the field of microbial preparations and fertilizer production, can solve the problems of reducing fertilizer effectiveness, adding, and low water content, and achieve the effects of improving fertilizer utilization, increasing cell number, and alleviating fertilizer compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

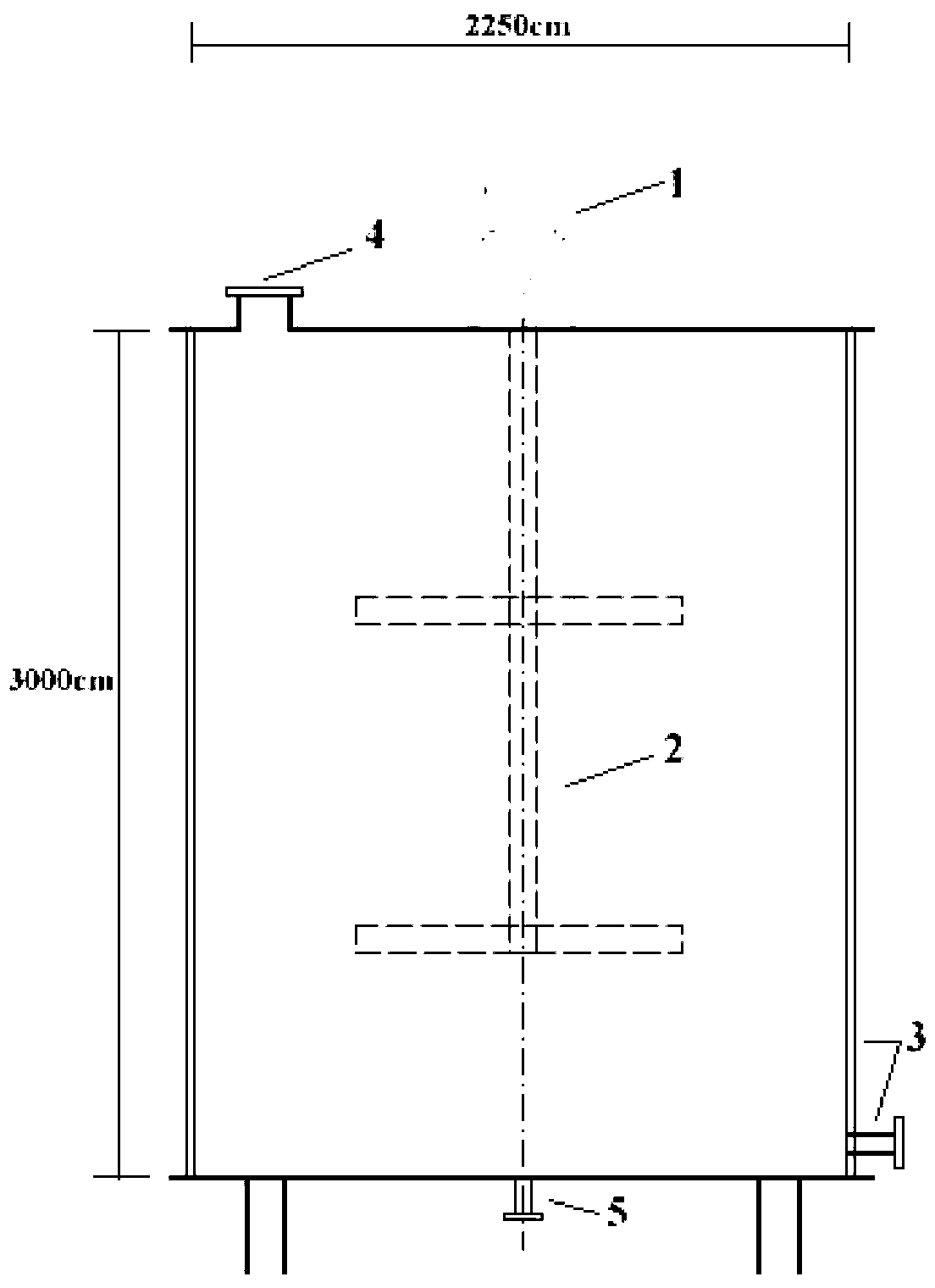

Image

Examples

Embodiment 1

[0022] Example 1 Production of anhydrous coated bio-organic fertilizer containing 200,000,000 / gram highly active Bacillus subtilis

[0023] Taking the production of a batch of 100 tons of anhydrous coated bio-organic fertilizer as an example, the coating agent accounts for about 1% of the weight of the fertilizer particles.

[0024] Put 530 kg of lard, 100 kg of solid paraffin and 40 kg of aliphatic amine into the heating barrel, stir at a constant speed of 20 rpm and heat up to 60°C to melt the material into a liquid state, and add it to the barrel after stabilizing for 1 hour Concentration is 330 kilograms of Bacillus subtilis bacterium powder of 60 billion / gram and simultaneously opens agitator paddle and stirs with 17rpm speed, continues to keep 60 ℃ of temperature and stirs for 10 minutes and makes it fully mix, obtains the microbial coating agent that is used to prepare microbial compound fertilizer .

[0025] Then open the self-priming pump connected to the outlet of t...

Embodiment 2

[0026] Example 2 The production of anhydrous coated microorganism organic-inorganic compound fertilizer containing 100 million / gram highly active Trichoderma viride

[0027] Taking the production of a batch of 150 tons of bio-organic-inorganic compound fertilizer as an example, the coating agent accounts for about 1% of the weight of the fertilizer particles.

[0028]Add 840 kg of liquid paraffin, 105 kg of petrolatum and 55 kg of polyethylene glycol into the heating barrel, stir at a constant speed of 17 rpm and heat up to 55°C to melt the material into a liquid state, and add the concentration to the barrel after stabilizing for 1.5 hours Be 500 kilograms of Trichoderma viride spore powder of 30 billion / gram and stir simultaneously with 17rpm speed, continue to keep 55 DEG C of temperature and stir for 5 minutes and make it fully mix, obtain the microbial coating agent that is used to prepare microbial compound fertilizer.

[0029] Turn on the self-priming pump at the outlet...

Embodiment 3

[0030] Example 3 Production of anhydrous coated microbial organic fertilizer containing 50 million / gram highly active nitrogen-fixing rhizobia

[0031] Taking the production of a batch of 200 tons of bio-organic fertilizer containing 50 million / g highly active nitrogen-fixing rhizobia as an example, the coating agent accounts for about 1% of the weight of the fertilizer granules.

[0032] Add 1290 kg of palm oil, 140 kg of microcrystalline paraffin and 70 kg of polyoxyethylene amine into the heating barrel, stir at a constant speed of 15 rpm and heat up to 50°C to melt the material into a liquid state, and add it to the barrel after being stable for 2 hours 500 kilograms contain the bacteria powder of 20,000,000,000 / gram nitrogen-fixing rhizobia, stir simultaneously with 15rpm speed, continue to keep 45-50 ℃ of temperature and stir 10 minutes and make it fully mix, obtain the microbial coating agent that is used to prepare microbial compound fertilizer.

[0033] Turn on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com