Xylitol genetic engineering bacteria and method for producing xylitol via mixed transformation by same

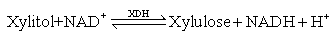

A technology of genetically engineered bacteria and xylitol, which is applied in the construction of xylitol genetically engineered bacteria, and in the field of mixed transformation of D-arabitol to produce xylitol, which can solve the problems of low conversion rate, complicated process, and complicated fermentation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the acquisition of genetically engineered bacteria with xylitol dehydrogenation high enzyme activity

[0030] According to the xylitol dehydrogenase gene sequence of Gluconobacter oxidans published in NCBI and the characteristics of the multiple cloning sites on the expression vector pSE380, a degenerate primer was designed and synthesized using bioinformatics software: P1: 5'TA CCATGG TTCACCACCATCATCACCATCATATGTCGAAGAAGTTTAAG3' (with Nco Ⅰ restriction site); P2: 5'TG AAGCTT TCAACCGCCAGC AAT3' (with Hind III restriction site).

[0031] The target gene was amplified by PCR using the genomic DNA of Gluconobacter oxydans as a template.

[0032] PCR reaction parameters: pre-denaturation: 95 ℃ 2min; denaturation: 94 ℃ 30sec; renaturation: 55 ℃ 30sec; extension: 72 ℃ 1min; cycle: 35; termination extension: 72 ℃ 10min; final 16℃ incubation

[0033] The PCR product was detected by 1% agarose electrophoresis, and the PCR product with a fragment size of ab...

Embodiment 2

[0046] Embodiment 2, preparation xylitol

[0047] (1) Gluconobacter oxidans was first cultured in the seed liquid medium, and 2-3 epoxidized Gluconobacter slant colonies were picked in 10 ml of the seed liquid medium, and cultured with shaking at 28°C and 100 rpm for 8 hours. Seed liquid medium includes: glucose 20.0 g / L, tryptone 1.0 g / L, yeast extract 2.0 g / L; Gluconobacter oxidans slant medium: glucose 20 g / L, tryptone 1 g / L, yeast extract 2 g / L, agar 10 g / L.

[0048] (2) The seed solution was inoculated into the expansion medium at an inoculation amount of 1%, and shaken at 28 °C and 100 rpm for 48 hours. The expansion medium included: glucose 20.0 g / L, yeast extract 2.0 g / L, tryptone 1.0 g / L, D-arabinitol 5.0 g / L, calcium carbonate 10.0 g / L.

[0049] (3) Centrifuge the fermentation broth in (2) at 6000 rpm at 4°C for 5 min, collect the bacteria sludge, wash twice with 0.1 mol / L potassium phosphate buffer of pH 6.8, resuspend with an appropriate amount of cell transfor...

Embodiment 3

[0051] Embodiment 3, preparation xylitol

[0052] (1) Gluconobacter oxydans was first cultured in the seed liquid medium, and 2-3 epoxidized Gluconobacter slant colonies were picked in 10 ml seed liquid medium, and cultured at 37 °C and 260 rpm for 20 h with shaking. The seed liquid medium includes: glucose 40.0 g / L, tryptone 10.0 g / L, yeast extract 20.0 g / L.

[0053] (2) The seed solution was inoculated into the expansion medium at an inoculation amount of 10%, and cultured with shaking at 37 °C and 260 rpm for 96 hours. The expansion medium includes: glucose 40.0 g / L, yeast extract 20.0 g / L, tryptone 10.0 g / L, D-arabitol 20.0 g / L, calcium carbonate 20.0 g / L; Gluconobacter oxidans slant medium: Glucose 40.0 g / L, tryptone 10.0 g / L, yeast extract 20.0 g / L, agar 20 g / L.

[0054] (3) Centrifuge the fermentation broth in (2) at 12,000 rpm at 4°C for 20 min, collect the bacteria sludge, wash twice with 0.1 mol / L potassium phosphate buffer of pH 6.8, resuspend with an appropriat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pre-denatured | aaaaa | aaaaa |

| Extend | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com