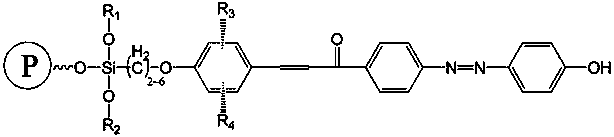

Optical intelligent silicagel surface molecularly imprinted microsphere and preparation method thereof

A surface molecular imprinting and molecular imprinting membrane technology, applied in the field of chemical engineering, can solve the problems of molecularly imprinted polymer molecular recognition and selectivity decline, template molecule target molecule processing capacity reduction, irregular shape, etc., to achieve mechanical strength and Good chemical stability, uniform particle size, and complete elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

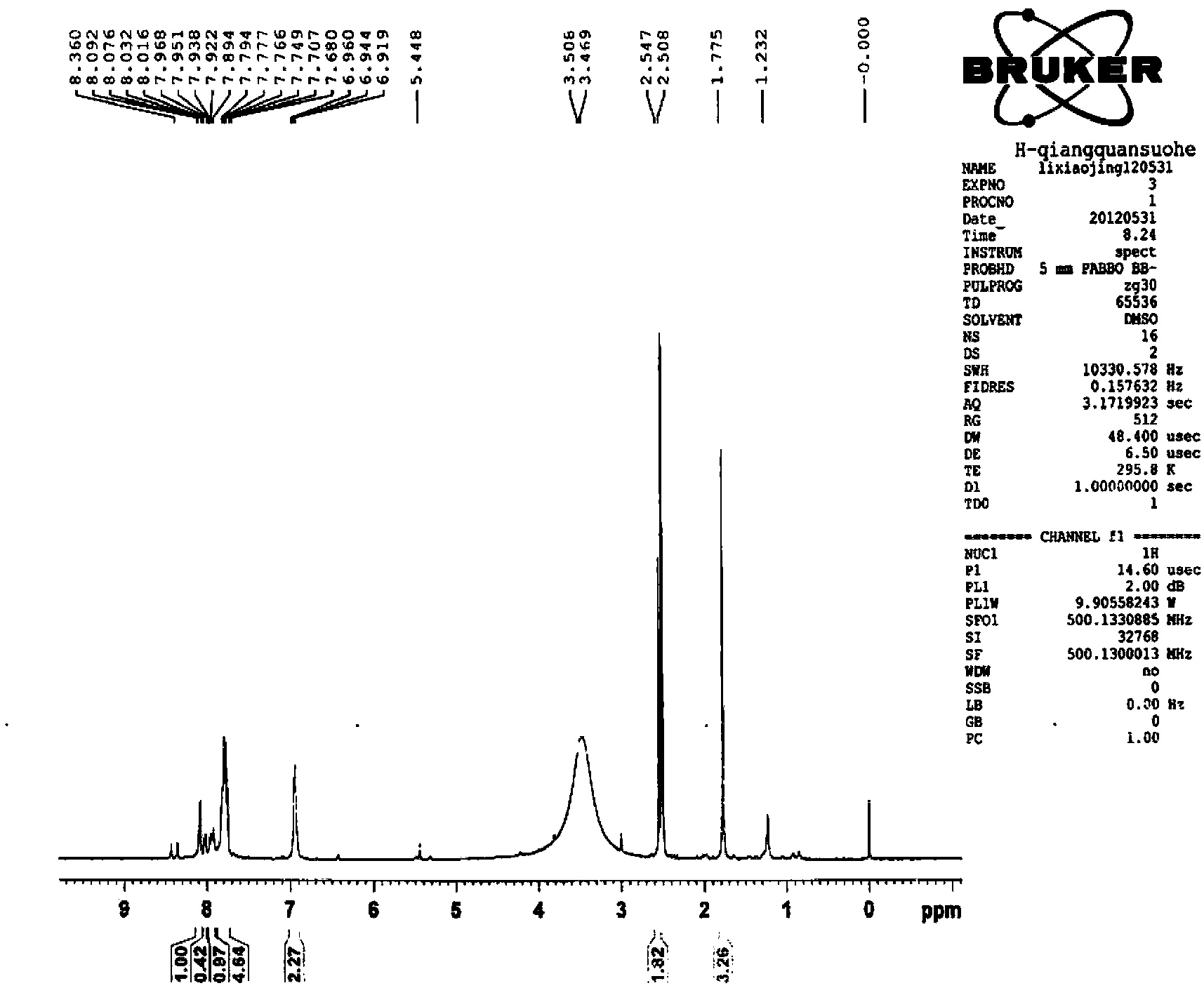

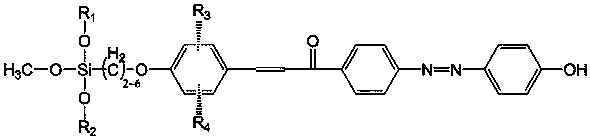

[0028] Synthesis of Functional Monomers of Azobenzene Derivatives

[0029]

[0030] 4-Aminoacetophenone and phenol were diazotized to synthesize 4-hydroxy-4'-acetyl azobenzene as raw materials. The specific synthesis steps were as follows: ①Put 2.7g of p-aminoacetophenone into a 100mL double-necked bottle , add 20mL of distilled water, then add 5.4mL of concentrated hydrochloric acid dropwise, and stir in an ice bath (0-5°C) for 10 minutes; dissolve 1.38g of sodium nitrite with 30mL of distilled water, and add dropwise to the double-necked flask Stir in an ice bath to generate diazonium salts. ②Dissolve 1.88g of phenol in 11mL of methanol, add it dropwise into the double-necked flask with a constant pressure separatory funnel, and stir for 2 hours. ③The reaction solution was neutralized to neutral with 5% sodium hydroxide solution, and a yellow solid was observed to form. Suction filtration, recrystallization with ethanol to obtain the product.

[0031] Step 2, p-Hydroxy...

Embodiment 2

[0034] Preparation of Molecularly Imprinted Microspheres on Silica Surface.

[0035] (1) Ethyl orthosilicate was stirred at a constant speed in ethanol solution containing ammonia water for 24 hours to synthesize silicon spheres with a particle size of 500 nm; the silicon spheres were stirred in aqueous nitric acid solution for 12 hours, filtered and washed, and vacuum-dried to constant weight.

[0036] The described ammonia solution concentration is 16.7%, and the nitric acid solution concentration is 50%.

[0037] Said uniform stirring, stirring speed: 500-600rpm; stirring temperature: 25°C.

[0038] For the washing, twice distilled water was used to wash three times.

[0039] The temperature of the vacuum drying is 110°C.

[0040] (2) Azobenzene derivatives are grafted onto the surface of activated silica spheres, and template molecules are added. The template molecules are chlorogenic acid in Eucommia leaves, oleanolic acid in privet leaves or dihydromyricetin in vine tea ...

Embodiment 3

[0048] one. Preparation of molecularly imprinted microspheres on the silica gel surface of chlorogenic acid:

[0049] (1) The molar ratio of chlorogenic acid, AIBN and EDMA is 0.2:0.2:2.5. Under dark conditions, 0.16g grafted silicon spheres, 0.2mmol chlorogenic acid were stirred in 15ml acetonitrile at 25°C for 2h, 0.2mmol AIBN, 2.5mmol EDMA were added to the reaction system, the temperature was raised to 60°C, and the reaction was carried out for 12h. (2) After the reaction, stir in DMSO at 60°C for 30 minutes, wash with 25ml of methanol for 3 times, and wash with 25ml of acetone for 2 times (remove the remaining dispersant, organic matter, etc.), each time for 10 minutes, ultrasonically oscillate during washing, and finally pass methanol : Soxhlet extraction with acetic acid (90:10) to further remove template molecules; (3) Dry the polymer silica gel from which template molecules have been removed to constant weight at 50°C in vacuum to obtain molecularly imprinted microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com