A method for measuring six components of coal tar

A technology for coal tar and distillate, which is applied in the field of coal tar component separation, can solve the problems of complex composition of coal tar and no separation and separation of other components, and achieves mild operating conditions, increased dosage and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

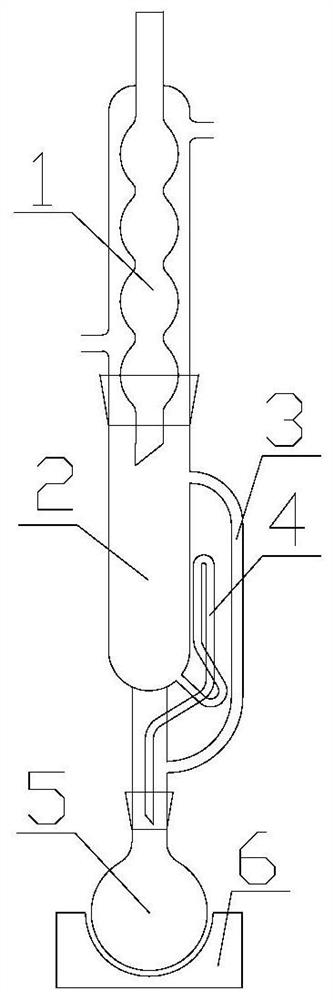

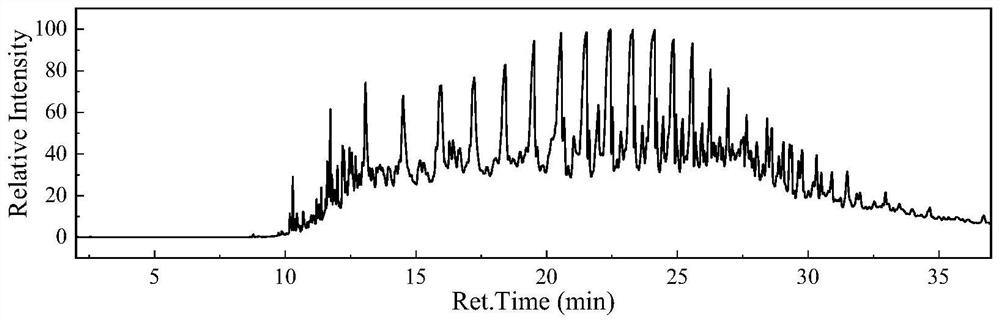

[0064] Embodiment 1, the method for measuring six components of coal tar

[0065] The experimental raw material is medium and low temperature coal tar light oil (oil in the upper layer of tar clarification tank) from Shenmu Xinyi Energy Chemical Industry Co., Ltd. in Yulin, northern Shaanxi.

[0066]1) Weigh 1g of medium-low temperature coal tar light oil into a 250mL No. 1 round bottom flask, then add 50mL of n-heptane, heat to reflux for 1-4h, and let it settle in a dark place for 1-4h.

[0067] 2) Pretreat the quantitative filter paper, specifically: soak the quantitative filter paper with n-heptane for 12 hours, and dry it for 12 hours for later use.

[0068] Pour the extract phase and raffinate phase in No. 1 round-bottom flask into a funnel equipped with pretreated quantitative filter paper for filtration, and the obtained filtrate is directly put into a rotary evaporator distillation flask; the residue in No. 1 round-bottom flask The mixture was washed with 40mL of n-h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com