Urease high-yielding Aspergillus sydowii and application thereof

A technique for producing Aspergillus polypolymosa and urease, which is applied in the field of microorganisms, can solve the problems such as Aspergillus polypolypolysaccharide that have not been reported, achieve great application and promotion value, improve safety and quality, and reduce the content of urea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 strain screening

[0032] 1. Primary screening of strains

[0033] Material: distiller's yeast used by Sichuan Jiannanchun (Group) Co., Ltd.

[0034] Medium: peptone 10.0g, glucose 18g, 0.4% phenolphthalein solution 3mL, sodium chloride 5.0g, potassium dihydrogen phosphate 2.0g, agar 20.0, distilled water 1000mL. Dissolve the above ingredients except phenolphthalein, adjust the pH to 6.8~6.9, and then add phenolphthalein indicator. Divide into triangular flasks and sterilize at 121°C for 15 minutes. When the culture medium is cooled to 50-55°C, add 20% urea aqueous solution that is pre-filtered and sterilized so that the final concentration in the medium is 2%, shake well and set aside .

[0035] Experimental method: Take 10 grams of distiller's yeast under aseptic conditions in a 25 mL Erlenmeyer flask filled with 90 mL of sterile water and glass beads, place it on a bed and shake it at room temperature for 30 minutes. The bacterial solution was diluted t...

Embodiment 2

[0041] The identification of embodiment 2JNC-U5 bacterial strain

[0042] 1. 18S rDNA sequence analysis

[0043] (1) DNA extraction

[0044] Collect the bacteria, dissolve in 5mL extraction buffer (100mM Tris Cl, 100mM EDTA-Na 2 , 200mM NaCl, 2%CTAB, pH8.0), shake at 37°C for 45min. Add 0.75mL 20% SDS, and bathe in water at 65°C for 1h. Centrifuge at 12,000rpm for 10min, and collect the supernatant. The supernatant was extracted twice with an equal volume of phenol: chloroform: isoamyl alcohol (25:24:1), added with a final concentration of 0.3M NaAC (pH 5.2) and 2 times the volume of absolute ethanol, and precipitated at room temperature for 1 h. 4°C, 12,000rpm, centrifuge for 20min, collect the precipitate, rinse twice with 70% ethanol, dry and dissolve in 50μL TE (10mmTris-HCl, 1mmNa 2 EDTA) to obtain total DNA.

[0045] (2) Amplification of 18S rDNA

[0046]Using the total DNA as a template, fungal universal primers 18SF (SEQ ID No. 2: CCAACCTGGTTGATCCTGCCAGTA) and 1...

Embodiment 3

[0060] Embodiment 3 Morphological characteristics and carbon source utilization characteristic identification of Aspergillus strain of the present invention

[0061] 1. Colony morphology and bacterial microscopic observation

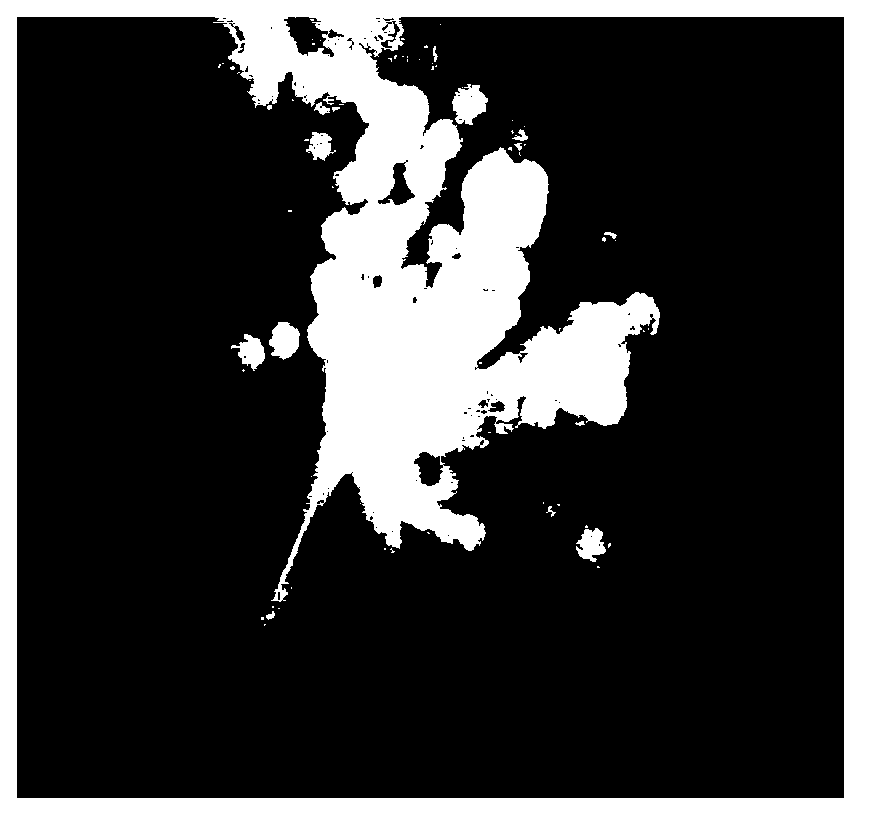

[0062] Activate the strains stored at 4°C with ME slant medium for 3 days, then use the inoculation needle to pick up the colonies on the slant and inoculate them on the ME plate medium, culture at 28°C for 7 days, observe the colony morphology, and observe the conidia under a microscope and the morphology of the spore spores (see figure 2 ). Quanta TM 450FEG to observe the ultrastructure of bacteria (see image 3 and Figure 4 ).

[0063] The Aspergillus colony grows radially on the ME medium, with radial grooves, and the diameter is about 22-30 mm after being cultured at 28°C for 7 days; the color is grayish green, with white halos around; the opposite side of the colony is light brown or dark brown. Conidiophores are born directly on the matrix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com