Bulky-grain rare earth carbonate and preparation method and application of carbonate

A rare earth carbonate, large particle technology, applied in rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that rare earth carbonate is not easy to obtain, the crystal form of carbonate precipitation is not good, and the environmental protection standard is difficult to handle. and other problems, to achieve the effect of shortened preparation cycle, low cost and less inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

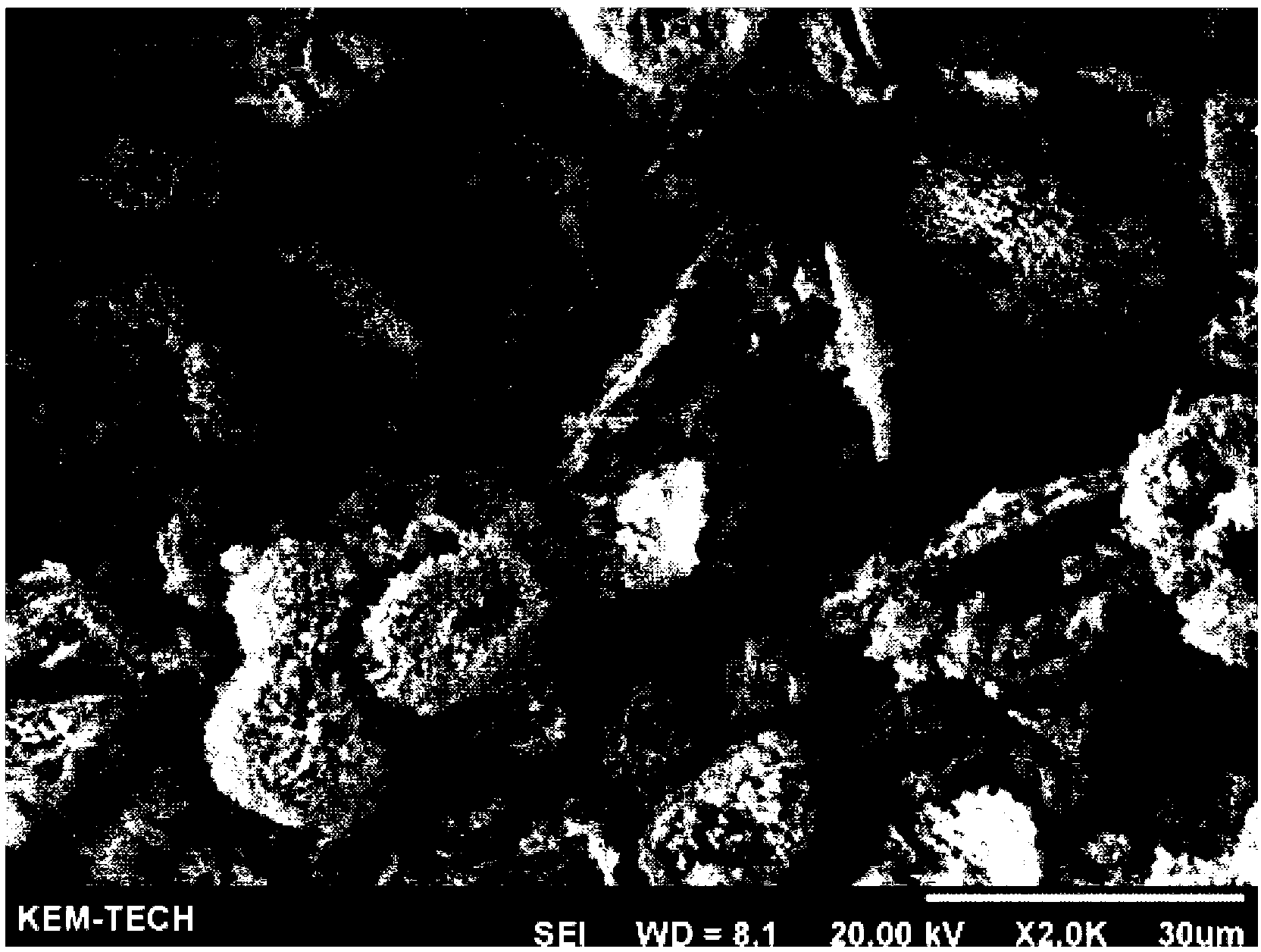

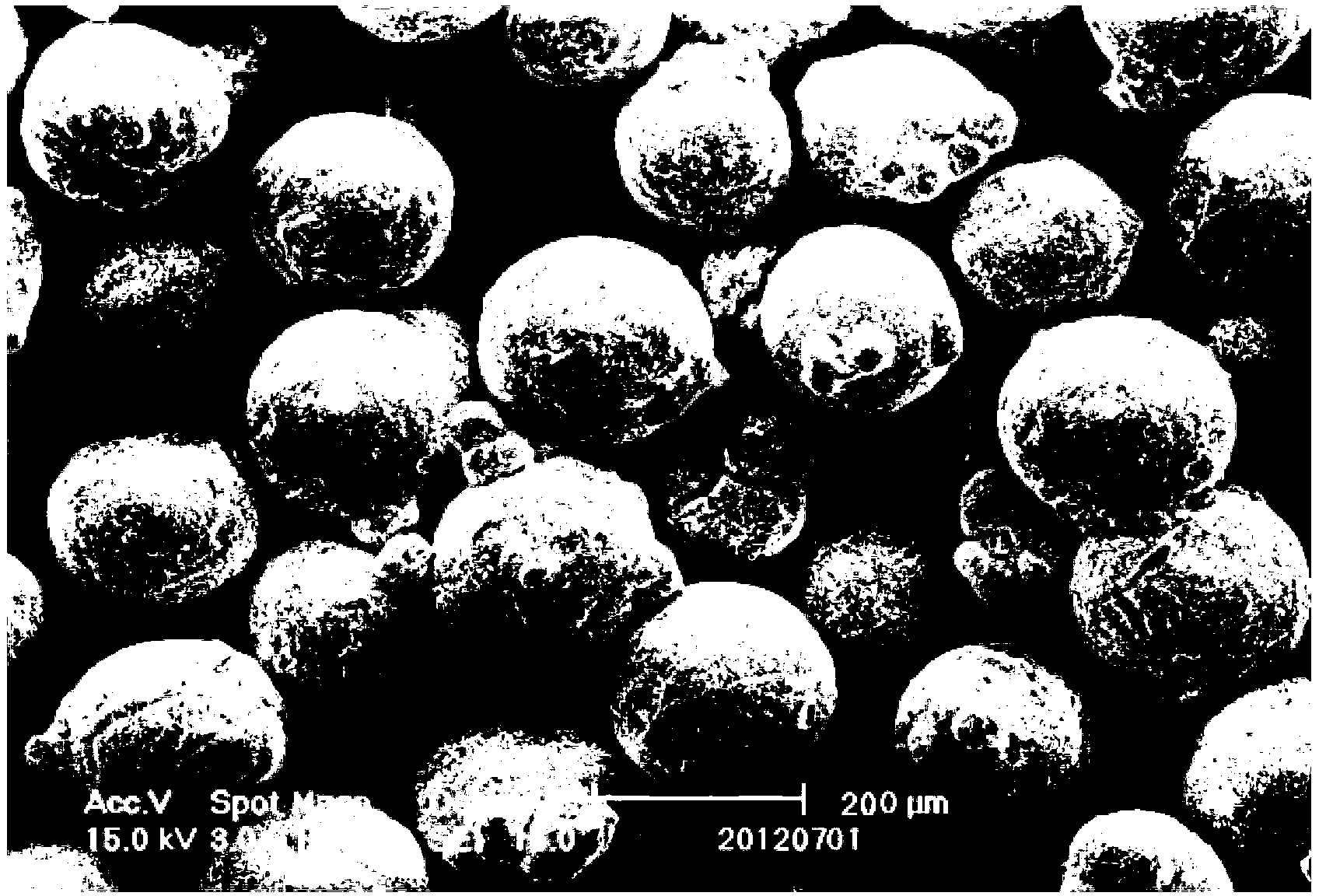

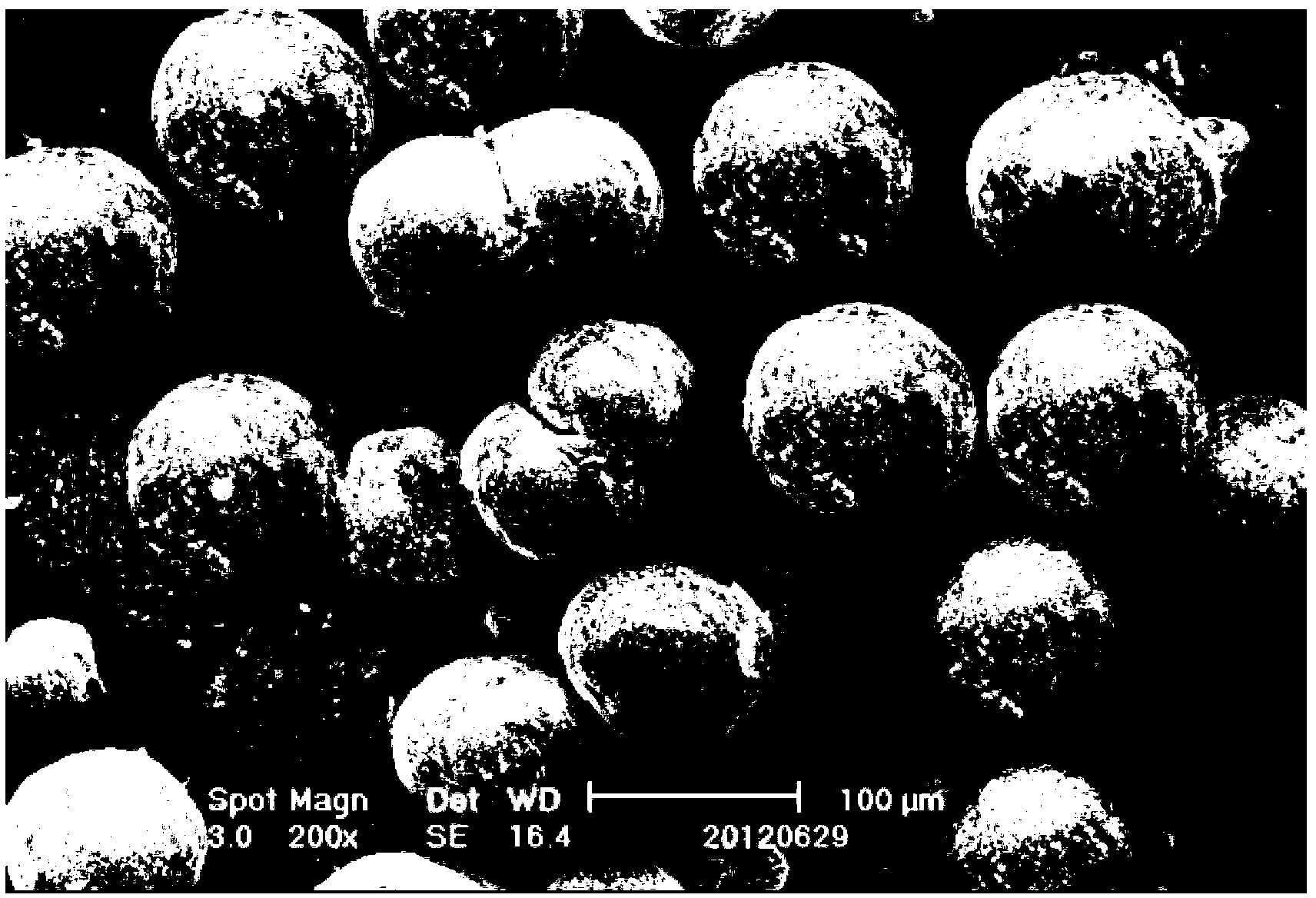

[0035] see figure 2 , image 3 . At room temperature, take 1.0 L of 0.5 mol / L yttrium chloride solution, add 10 ml of 1% PAA solution, adjust the stirring speed to 100 rpm, and add 0.5 mol / L sodium carbonate solution to the feed solution until the pH value End when reaching 6.0, obtain rare earth carbonate precipitate, stop stirring, age for 12h, the precipitate is filtered, washed, dehydrated and dried to obtain yttrium carbonate, the detection particle size D50 is 201.9 μm, and the electron microscope observation is that the whole particle morphology is spherical (such as figure 2 As shown), the size is uniform; the yttrium carbonate is calcined in a muffle furnace at 900 ° C for 3 hours, and the obtained yttrium oxide is still spherical in shape (such as image 3 shown), the size is uniform, and the detection particle size D50 is 102.8 μm.

Embodiment 2

[0037] Take 1.0L of praseodymium-neodymium nitrate solution with a concentration of 1.0mol / L, heat it to 40°C, add 5ml of 1% PAA solution, adjust the stirring speed at 150 rpm, and add a sodium bicarbonate solution with a concentration of 1.0mol / L to the feed liquid until When the pH value reaches 5.5, the rare earth carbonate precipitate is obtained, the stirring is stopped, and it is aged for 6 hours. The precipitate is filtered, washed, dehydrated and dried to obtain praseodymium neodymium carbonate, and the detected particle size D50 is 92.8 μm. Spherical and uniform in size; calcining the NdPr2CO3 in a muffle furnace at 1000°C for 5 hours to obtain NdPr2O3 particles are all spherical in shape and uniform in size by electron microscope observation, and the detected particle size D50 is 55.6 μm.

Embodiment 3

[0039] Take 1.0L of lanthanum chloride solution with a concentration of 2.0mol / L, heat it to 50°C, add 1ml of 1% PVA solution, adjust the stirring speed to 250 rpm, and add a sodium carbonate solution with a concentration of 2.0mol / L to the feed solution, When the pH value reaches 6.5, the rare earth carbonate precipitate is obtained, the stirring is stopped, and the precipitation is aged for 6 hours. The precipitate is filtered, washed, dehydrated and dried to obtain lanthanum carbonate, and the detected particle size D50 is 60.2 μm. Spherical and uniform in size; the lanthanum oxide obtained by calcining the lanthanum carbonate in a muffle furnace at 1000°C for 2 hours was spherical in shape and uniform in size as observed by the electron microscope, and the detected particle size D50 was 30.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com