Modified tripropylene glycol diacrylate and preparation method thereof

A technology of tripropylene glycol diacrylate and tripropylene glycol, which is applied in the field of modified tripropylene glycol diacrylate and its preparation, can solve the problems of large environmental pollution, poor environmental protection performance, low product yield, etc. The effect of fast curing rate, less by-products and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

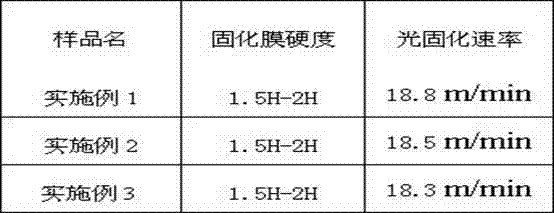

Examples

Embodiment 1

[0024] The preparation method of modified tripropylene glycol diacrylate, it may further comprise the steps:

[0025] (1) 40 parts of tripropylene glycol, 5 parts of polyester diol PD, 3 parts of pentaerythritol, 35 parts of acrylic acid, 2 parts of catalyst p-toluenesulfonic acid, 0.105 parts of polymerization inhibitor (polymerization inhibitor includes p-hydroxy Anisole 1000ppm, copper chloride 200ppm), cyclohexane 20 parts, put into the reactor and stir evenly, open the steam valve and heat slowly, control the steam pressure at 0.5Mpa, raise the temperature to 70~80°C, and keep it for 30 minutes, keep The vapor pressure is 0.5Mpa, and then the temperature is raised to 90~93°C. After 5 hours of reaction, the temperature is controlled to 93°C, refluxed for 12~15 hours, and the sample is sent for inspection. When the esterification acid value is 40~50mg KOH / g, stop reaction, standby;

[0026] (2) get the product after the esterification of step (1) into the washing kettle th...

Embodiment 2

[0029] The preparation method of modified tripropylene glycol diacrylate, it may further comprise the steps:

[0030] (1) 30 parts of tripropylene glycol, 3 parts of polyester diol PD, 3 parts of pentaerythritol, 30 parts of acrylic acid, 1 part of catalyst methanesulfonic acid, 0.09 part of polymerization inhibitor (polymerization inhibitor comprises p-hydroxyanisole 1000ppm, copper chloride 100ppm, 15 parts of n-hexane, put into the reactor and stir evenly, open the steam valve and heat slowly, control the steam pressure at 0.6Mpa, raise the temperature to 70~80℃, keep it for 40 minutes, then raise the temperature to 90~93 ℃, after reacting for 4 hours, raise the temperature to 93~95℃, reflux for 12~15 hours, take a sample for inspection, and when the esterification acid value is 40~50mg KOH / g, stop the reaction and set aside;

[0031] (2) get the product after the esterification of step (1) into the washing kettle through a pump, wash three times with a concentration of 15...

Embodiment 3

[0034] The preparation method of modified tripropylene glycol diacrylate, it may further comprise the steps:

[0035] (1) 50 parts of tripropylene glycol, 8 parts of polyester diol PD, 8 parts of pentaerythritol, 45 parts of acrylic acid, 9 parts of catalyst silicotungstic acid, 0.135 parts of polymerization inhibitor (polymerization inhibitor includes p-hydroxyanisole 3000ppm, 200ppm ferrous sulfate, 300ppm copper chloride), 30 parts of benzene, put into the reactor and stir evenly, open the steam valve and heat slowly, control the steam pressure at 0.5Mpa, raise the temperature to 70~80°C, keep it for 50 minutes, and then raise the temperature to 90~93°C, after reacting for 5 hours, raise the temperature to 93~95°C, reflux for 12~15 hours, take a sample for inspection, and when the esterification acid value is 40~50mg KOH / g, stop the reaction and set aside;

[0036] (2) get the product after the esterification of step (1) into the washing kettle through a pump, wash three ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com