Plukenetia volubilis linneo health-care nougat

A technology of nougat and vine fruit, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of affecting the flavor of nougat, unacceptable to consumers, unfavorable to human health, etc. The effect of preventing osteoporosis and beneficial to gastrointestinal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

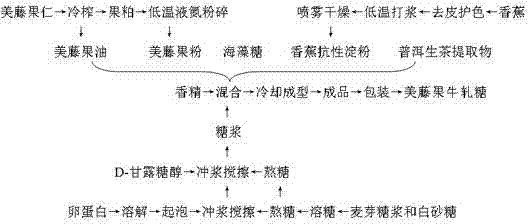

Method used

Image

Examples

preparation example Construction

[0038] 4. Glycosome preparation

[0039] A. To dissolve the foaming agent, take 1-5 parts of egg protein and mix well, add 1-8 parts of cold water to soak for 1.5-3.5 hours, transfer to a heating pot, stir at a temperature of 70-90°C and a stirring speed of 800-1000r / min to dissolve completely;

[0040] B. Foaming, transfer 1 to 3 parts of foaming agent and diglycerin fatty acid ester prepared in step A to a stirring machine, and stir to form a white and crisp bubble base at a stirring speed of 1200 to 1500 r / min;

[0041] C. To dissolve sugar, weigh 5-20 parts of maltose syrup, 5-20 parts of white granulated sugar, 1.5-2 parts of hot water at a temperature of 80-100°C, and stir at a stirring speed of 600-800r / min to completely dissolve it. spare;

[0042] D, boil sugar, pour the sugar solution melted in step C into a heating pot and boil, the stirring speed is 600-800r / min, the boiling temperature is 110-130°C, and the boiling time is 15-30h;

[0043] E. Slurry stirring a...

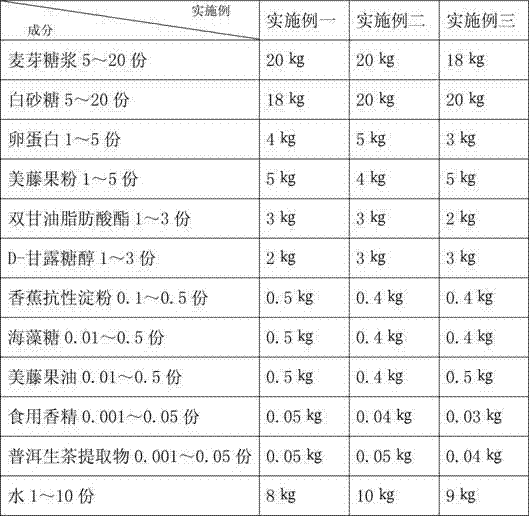

Embodiment 1

[0049] 1. Using cold pressing technology to extract saiteng fruit oil: crush the saiteng fruit kernels to 80 mesh, press at a temperature of 35°C, press for 45 minutes, and press at a pressure of 50 MPa to produce saiteng fruit oil;

[0050] 2. Utilize the low-temperature liquid nitrogen crushing technology to prepare saiteng fruit powder: use the pulp after extracting the sachaeto fruit oil, and crush it at -25°C, the liquid nitrogen feed rate is 500mL / min, and the fruit pulp feed rate is 1000g / min. Crush the fruit pulp to 100 mesh to prepare saiteng fruit powder;

[0051] 3. Spray drying technology to prepare banana resistant starch: select unripe green bananas and peel them, then use 0.15% food grade citric acid and 0.14% vitamin C to protect the color, beat at -20°C at low temperature, and spray The drying inlet temperature is 230°C, the spray drying outlet temperature is 80°C, the air inlet pressure is 0.3MPa, and the feed rate is 15 mL / min to prepare banana resistant sta...

Embodiment 2

[0063] 1. Use cold pressing technology to extract saiteng fruit oil: crush saiteng nuts to 60 mesh, press at 45°C, press for 60 minutes, and press at a pressure of 60 MPa to produce saiteng fruit oil;

[0064] 2. Utilize the low-temperature liquid nitrogen crushing technology to prepare satoshi fruit powder: use the pulp after extracting the sachaeto fruit oil, and grind it at -20°C, the amount of liquid nitrogen is 500mL / min, and the amount of pulp is 800g / min. Crush the fruit meal to 80 meshes to prepare saiteng fruit powder;

[0065] 3. Spray-drying technology to prepare banana resistant starch: select unripe green bananas and peel them, then use 98% food grade citric acid 0.3% and vitamin C 0.1% to protect the color, perform low-temperature beating at -30°C, and spray The drying inlet temperature is 200°C, the spray drying outlet temperature is 100°C, the air inlet pressure is 0.1MPa, and the feed rate is 24 mL / min to prepare banana resistant starch;

[0066] 4. Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com