Preparation method of titanium surface porous structure layer bioactive ceramic membrane with low elasticity modulus

A technology of bioactive ceramics and low elastic modulus, applied in coatings, medical science, prostheses, etc., can solve the problems of unfavorable implants bearing load for a long time, chronic fatigue of bone tissue, high surface elastic modulus, etc., to achieve Achieve the effect of biological function, good nail anchoring and ossification, high strength and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Pure titanium TC2 is selected as the solid structure of the implant

[0039] 2. Chemical degreasing:

[0040] Sodium hydroxide 50g / L, sodium phosphate 5g / L, the rest is water; temperature: 30°C; time 5 minutes;

[0041] 3. Pickling:

[0042] 70% (volume concentration) HNO 3 10ml / L, citric acid 5g / L, and the rest is water. Temperature: room temperature, process for 2 minutes, wash with tap water for 1 to 2 minutes immediately after taking it out, and then wash with deionized water for 1 to 2 minutes.

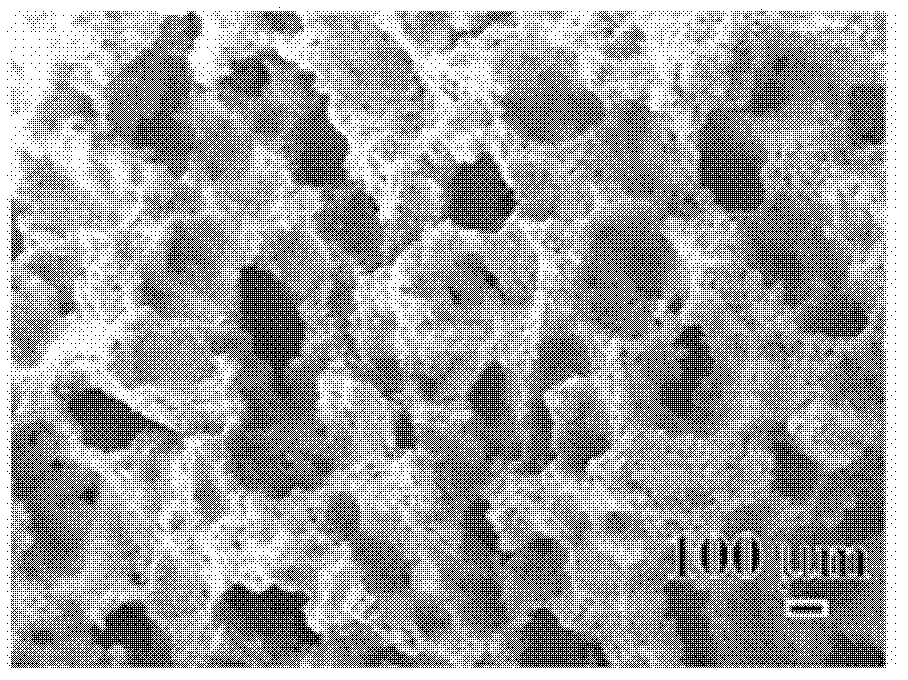

[0043] 4. Preparation of porous layer by powder metallurgy method:

[0044] The pure titanium powder and urea powder are mixed, the average particle size of the pure titanium is 30 microns, the urea powder is used as a space support, and the particle size of the urea powder is 50 microns. The ratio of pure titanium to urea powder is determined according to the porosity of the porous structure layer to be obtained, and the porosity is preferably 50%. The pure titan...

Embodiment 2

[0060] 1. Pure titanium TC4 is selected as the solid structure of the implant

[0061] 2. Chemical degreasing:

[0062] Sodium hydroxide 50g / L, sodium phosphate 5g / L, the rest is water; temperature: 30°C; time 5 minutes;

[0063] 3. Pickling:

[0064] 40% (volume concentration) HF4ml / L, 95% (volume concentration) H 2 SO 4 10ml / L, tartaric acid 10g / L, and the rest is water. Temperature: room temperature, process for 2 minutes, wash with tap water for 1 minute immediately after taking it out, and then wash with deionized water for 1 minute, the thickness of the passivation film is 1 μm.

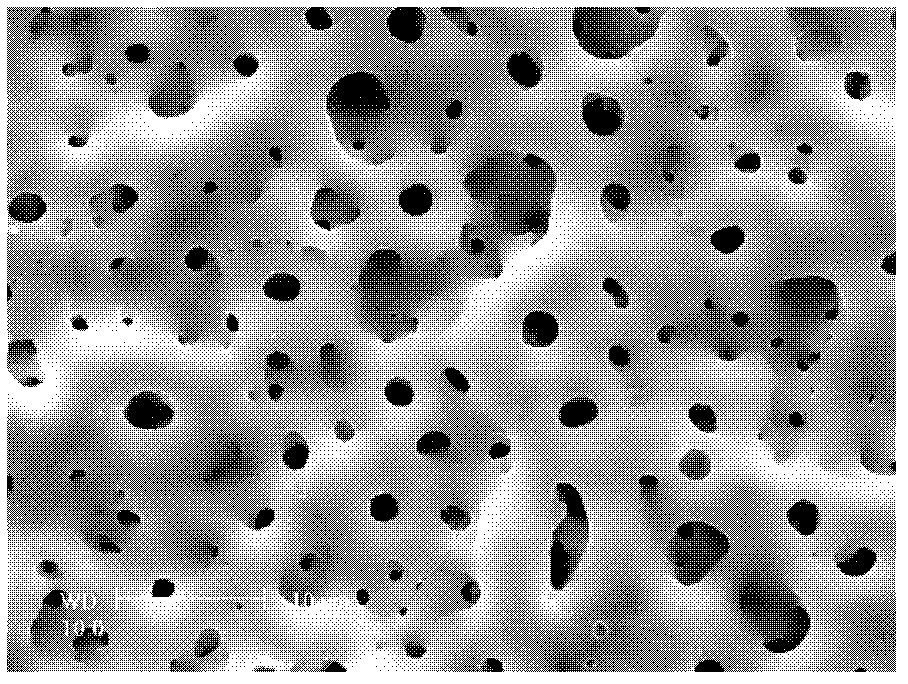

[0065] 4. Preparation of porous layer by powder metallurgy method:

[0066] The pure titanium powder and urea powder are mixed, the average particle size of the pure titanium is 30 microns, the urea powder is used as a space support, and the particle size of the urea powder is 80 microns. The ratio of pure titanium to urea powder is determined according to the porosity of the porous struc...

Embodiment 3

[0081] 1. Ti6Al4V is selected as the solid structure of the implant

[0082] 2. Chemical degreasing:

[0083] Sodium hydroxide 50g / L, sodium phosphate 5g / L, the rest is water; temperature: 30°C; time 5 minutes;

[0084] 3. Pickling:

[0085] 70% (volume concentration) HNO 3 4ml / L, 95% (volume concentration) H 2 SO 4 8ml / L, oxalic acid 5g / L, and the rest is water. Temperature: room temperature, treat for 3 minutes, wash with tap water for 1 minute after taking it out, and then wash with deionized water for 1 minute, the thickness of the passivation film is 1 μm.

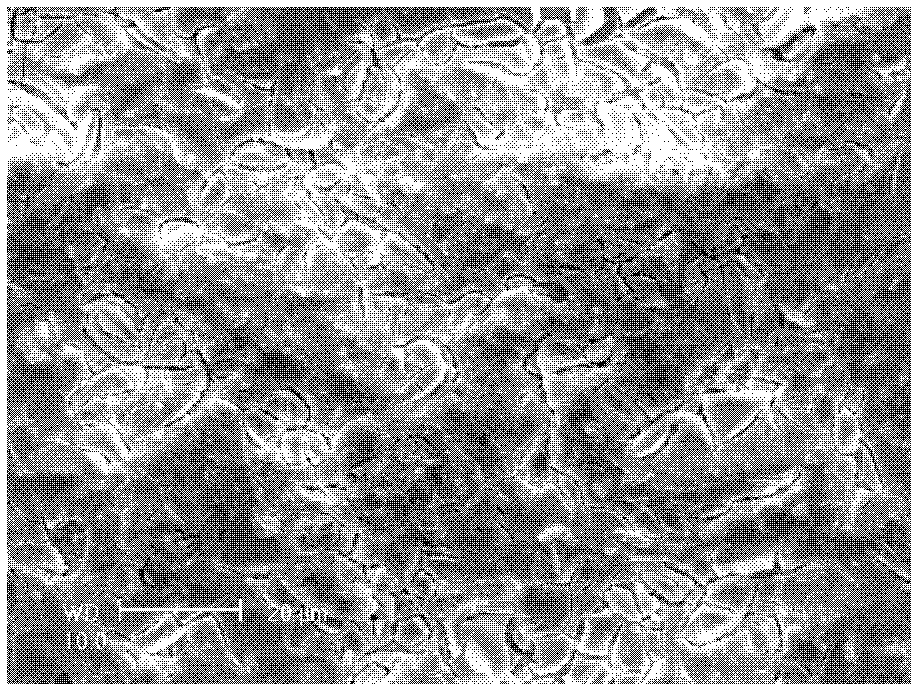

[0086] 4. Preparation of porous layer by powder metallurgy method:

[0087] Mix pure titanium powder and urea powder, the average particle size of pure titanium is 40 microns, urea powder is used as a space support, the particle size of urea powder is 70 microns, the ratio of titanium alloy to urea powder can be obtained as required The porosity of the porous structure layer is determined, and the porosity is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com