Organic semiconductor thin film solar cell preparation method based on nickel oxide anode interface layer

An organic semiconductor and solar cell technology, applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, coatings, etc., can solve the problem of high-power pulsed lasers being expensive, unable to obtain uniform nickel oxide films, and unsatisfactory quality of nickel oxide films, etc. problems, to achieve the effect of high light transmittance, high longevity, compact structure, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete steps of preparation are:

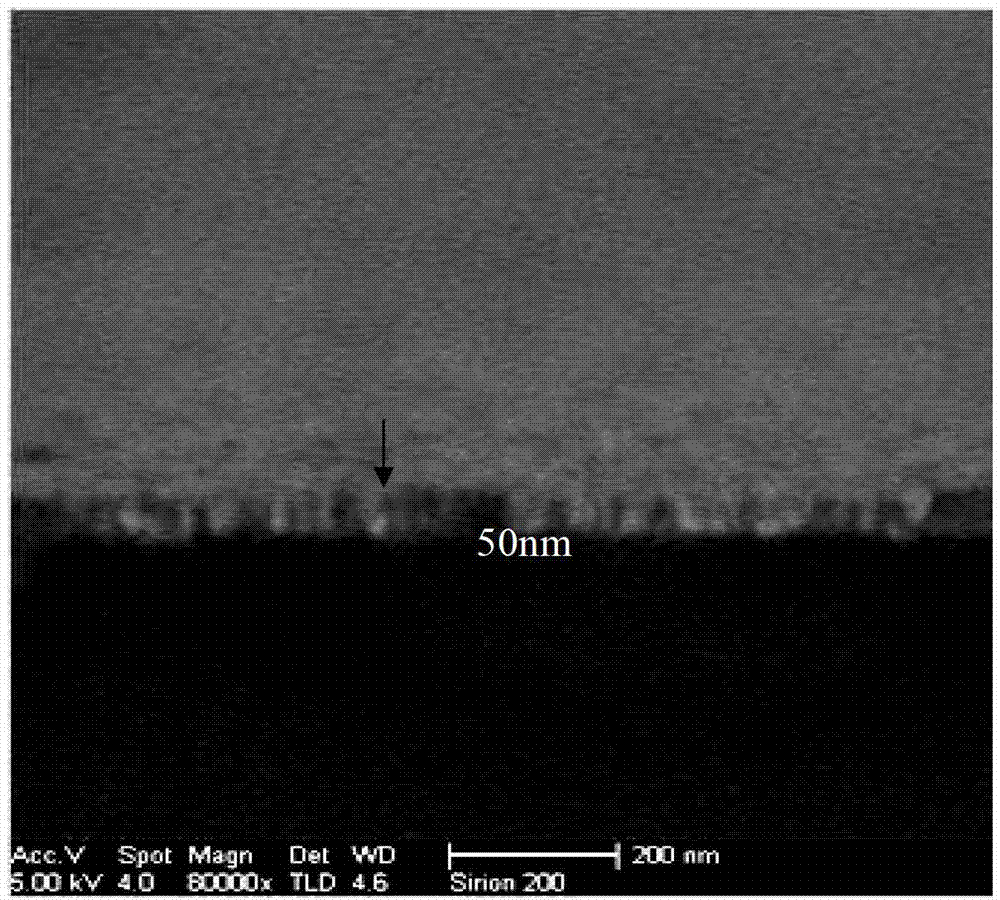

[0020] In step 1, the transparent conductive substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and then blown dry with nitrogen; wherein, the transparent conductive substrate is a conductive film. Then place the nickel oxide bulk target and the transparent conductive substrate on the cathode and the sample stage in the vacuum chamber of the radio frequency magnetron sputtering equipment respectively; wherein, the distance between the nickel oxide bulk target and the transparent conductive substrate is 8cm. The vacuum degree of the vacuum chamber is ≤1×10 -4 After Pa, the vacuum chamber was placed in an argon atmosphere with a pressure of 5Pa, and sputtered for 5min; wherein, the sputtering power was 150W, and the surface covered with figure 1 The nickel oxide film is shown as a transparent conductive substrate.

[0021] Step 2, first mix poly(3-hexylthiophene), [6,6]-phenyl-C 61 -Methyl butyrate an...

Embodiment 2

[0024] The concrete steps of preparation are:

[0025] In step 1, the transparent conductive substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and then blown dry with nitrogen; wherein, the transparent conductive substrate is a conductive film. Then place the nickel oxide bulk target and the transparent conductive substrate on the cathode and the sample stage in the vacuum chamber of the radio frequency magnetron sputtering equipment respectively; wherein, the distance between the nickel oxide bulk target and the transparent conductive substrate is 9 cm. The vacuum degree of the vacuum chamber is ≤1×10 -4 After Pa, the vacuum chamber was placed in an argon atmosphere with a pressure of 4 Pa, and sputtered for 11 minutes; wherein, the sputtering power was 138W, and the surface covered with figure 1 The nickel oxide film is shown as a transparent conductive substrate.

[0026] Step 2, first according to the weight ratio of 0.95:0.85:99, poly(3-hexy...

Embodiment 3

[0029] The concrete steps of preparation are:

[0030] In step 1, the transparent conductive substrate is ultrasonically cleaned with acetone, ethanol and deionized water, and then blown dry with nitrogen; wherein, the transparent conductive substrate is a conductive film. Then place the nickel oxide bulk target and the transparent conductive substrate on the cathode and the sample stage in the vacuum chamber of the radio frequency magnetron sputtering equipment respectively; wherein, the distance between the nickel oxide bulk target and the transparent conductive substrate is 10 cm. The vacuum degree of the vacuum chamber is ≤1×10 -4 After Pa, the vacuum chamber was placed under an argon atmosphere with a pressure of 3 Pa, and sputtered for 17 minutes; wherein, the sputtering power was 125W, and the surface covered with figure 1 The nickel oxide film is shown as a transparent conductive substrate.

[0031] Step 2, first mix poly(3-hexylthiophene), [6,6]-phenyl-C 61 -Methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

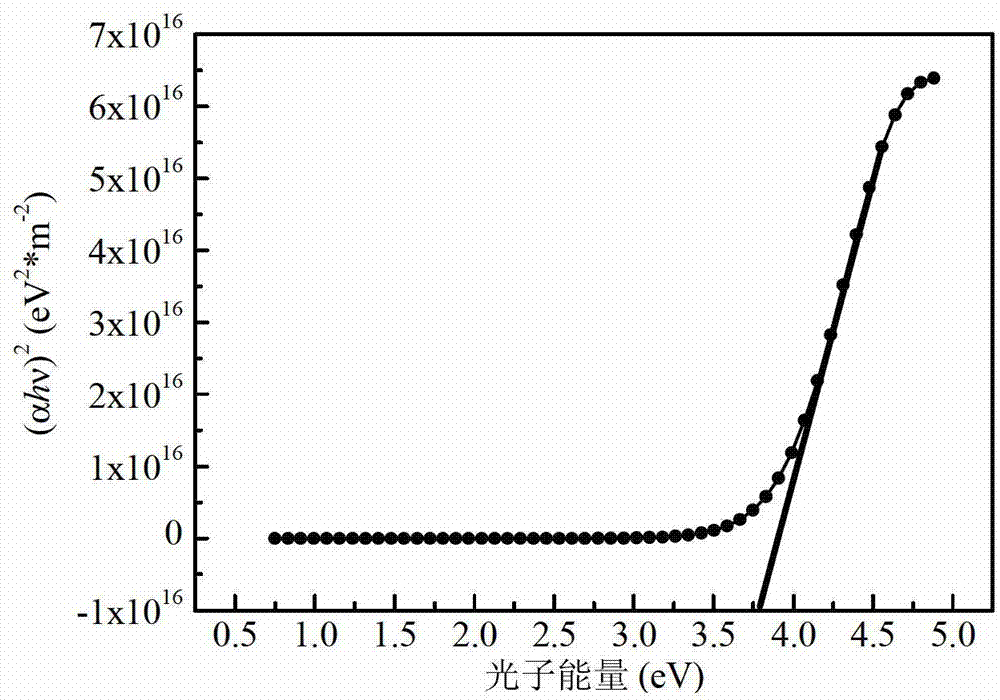

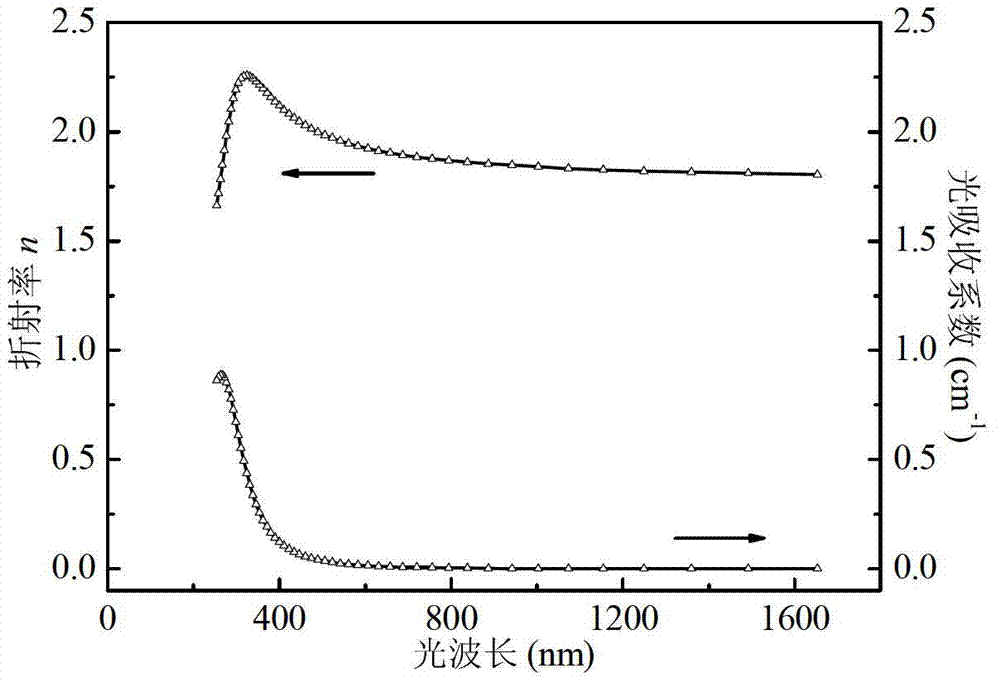

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com