Compound-type anion-exchange membrane and preparation method thereof

An anion-exchange membrane and composite technology, which is applied in the field of preparation of composite quaternized polyethersulfone anion-exchange membranes, can solve problems such as use restrictions, and achieve the effects of uniform structure, high ion conductivity, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the composite polyethersulfone anion exchange membrane involved in the present invention, by changing the structure of the aromatic dihalide (I), the aromatic dihydric phenol (II) with chloromethylation reaction active sites and Polyethersulfone polymers (PES) with different structures were synthesized by the structure, ratio and dosing method of aromatic dihydric phenol (III) without reactive sites; by changing the amount of Friedel-Crafts reaction catalyst, reaction temperature and time to Control the degree of chloromethyl substitution of the polymer to obtain different types of chloromethylated polyethersulfone polymers (CMPES); then use the solution blending method to cast PES and CMPES with different mass ratios to form a film, and undergo a quaternization reaction And alkaline ion exchange to prepare anion exchange membrane. The steps are as follows:

[0032] The first step, the preparation of polyethersulfone polymer precursor (PES)

...

Embodiment 1

[0066] Example 1: Preparation of composite quaternized polyethersulfone anion exchange membrane QPES(3 / 1)-3 / 7

[0067] Preparation of PES (3 / 1) polymer: In a completely dry four-neck flask equipped with nitrogen inlet and outlet devices, oil-water separator, and separatory funnel, under nitrogen protection, add 1.524g of DFDPS (6mmol) , 18 mL of NMP, 1.576 g of BHPF (4.5 mmol), 0.504 g of HFBPA (1.5 mmol), 0.954 g of potassium carbonate (6.9 mmol), and 18 mL of toluene. Slowly warming up to 140°C for reflux for 4h, the moisture generated by the reaction was removed in the form of toluene / water azeotrope. Then the temperature was slowly raised to 170°C, and the temperature was kept constant for 6h. After the reaction was over, the heating was stopped and cooled to room temperature. The product was slowly poured into about 500 mL of deionized water, and a white fibrous polymer product was precipitated. The product was fully washed with deionized water and dried in a vacuum ov...

Embodiment 2

[0071] Example 2: Preparation of composite quaternized polyethersulfone anion exchange membrane QPES(3 / 1)-4 / 6

[0072] Similar to the preparation method of QPES(3 / 1)-3 / 7 in Example 1, the difference is that the polymer precursor is mixed with the polymer after chloromethylation in a mass ratio of 4 / 6 during film formation Post-cast film.

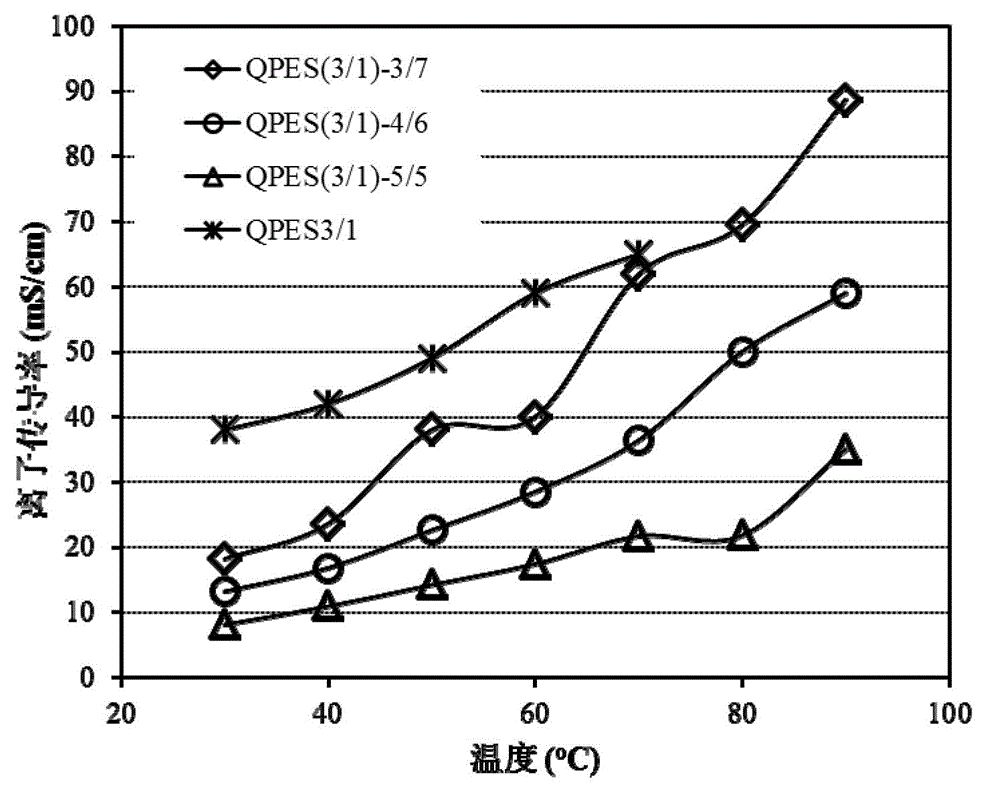

[0073] Its performance data is shown in Table 1, and the conductivity at different temperatures is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com