Preparation method of heat shrinkable polyester film

A technology of copolyester and heat shrinkage, applied in the preparation of copolyester film and the preparation of heat shrinkable copolyester film, can solve the problems of unsatisfactory tensile strength, shrinkage uniformity, no heat shrinkage rate, etc. Excellent transparency, uniform shrinkage, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

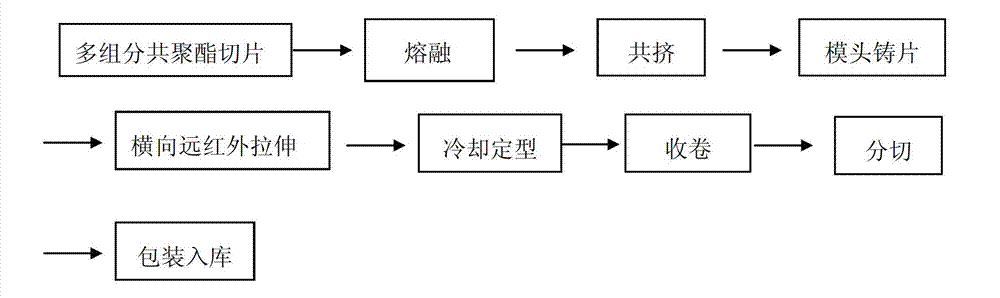

Method used

Image

Examples

Embodiment 1

[0025] Add 2.5Kg purified terephthalic acid, 2.5Kg multi-component dibasic acid (including naphthalene dicarboxylic acid, isophthalic acid, biphenyl dicarboxylic acid), 2.8Kg ethylene glycol, 0.5Kg Multi-component glycols (including isosorbide, butylene glycol, diethylene glycol, triethylene glycol, 1,4-cyclohexanedimethanol, neopentyl glycol) and 9 g ethylene glycol antimony catalyst, 160 g titanium dioxide Anti-adhesive agent, 10g silicate modifier, 1.2g stearamidopropyl dimethyl-β-hydroxyethylammonium dihydrogen phosphate antistatic agent, 0.9g isocyanate chain extender, at 230~260℃ , 0.2 ~ 0.3Mpa conditions for esterification, when the water output reaches 1100mL theoretical value, release the system pressure to normal pressure.

[0026] React under these conditions, add 1.6g of triethyl phosphate stabilizer, stir at normal pressure for 7 minutes, raise the temperature in the reactor to 285°C, and drop the pressure below 100Pa, react under these conditions for 3 hours, and...

Embodiment 2

[0029]Add 2.6Kg purified terephthalic acid, 2.4Kg multi-component dibasic acid (including naphthalene dicarboxylic acid, isophthalic acid, biphenyl dicarboxylic acid), 2.7Kg ethylene glycol, 0.6Kg Multi-component diols (including isosorbide, butanediol, diethylene glycol, triethylene glycol, 1,4-cyclohexanedimethanol, neopentyl glycol) and 8g tetrabutyl titanate catalyst, 150g Titanium dioxide anti-adhesive agent, 20g silicate modifier, 1.1g stearamidopropyl dimethyl-β-hydroxyethyl ammonium dihydrogen phosphate antistatic agent, 0.8g isocyanate chain extender, at 230-260 The esterification reaction is carried out under the conditions of 0.2-0.3Mpa and 0.2-0.3Mpa, and when the water output reaches the theoretical value of 1100mL, the system pressure is released to normal pressure.

[0030] React under these conditions, add 1.5g of triethyl phosphate stabilizer, stir at normal pressure for 7 minutes, raise the temperature in the reactor to 285°C, and drop the pressure below 100P...

Embodiment 3

[0033] Add 2.7Kg purified terephthalic acid, 2.3Kg multi-component dibasic acid (including naphthalene dicarboxylic acid, isophthalic acid, biphenyl dicarboxylic acid), 2.6Kg ethylene glycol, 0.7Kg Multi-component glycols (including isosorbide, butanediol, diethylene glycol, triethylene glycol, 1,4-cyclohexanedimethanol, neopentyl glycol) and 9g antimony acetate catalyst, 130g titanium dioxide anti-sticking Binder, 30g silicate modifier, 1.2g stearamidopropyldimethyl-β-hydroxyethylammonium dihydrogen phosphate antistatic agent, 0.9g isocyanate chain extender, at 230~260℃, 0.2 The esterification reaction is carried out under the condition of ~0.3Mpa, and when the water output reaches the theoretical value of 1100ml, the system pressure is released to normal pressure.

[0034] React under these conditions, add 1.6g of triethyl phosphate stabilizer, stir at normal pressure for 9 minutes, raise the temperature in the reactor to 285°C, and drop the pressure below 100Pa, react under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| preheating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com