Seed crystal-free self-assembly hydrothermal synthesis method of hydrophilic zeolite membrane

A zeolite membrane and hydrophilic technology, applied in the field of chemical separation, can solve the problems of high cost, high cost, low output, etc., and achieve the effects of easy repetition, modification of carrier pores, and smooth carrier surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Hydrothermal preparation method of NaA zeolite membrane:

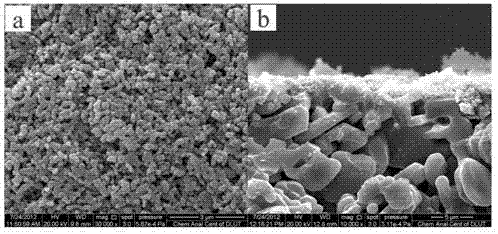

[0031] (1) Preparation of inorganic particle coating

[0032] α-Al after pretreatment by two-step thermal dipping 2 o3 Coating Continuous and Uniform Functionalized α-Al on Macroporous Support Tube 2 o 3 Particle coating: the pretreated α-Al 2 o 3 Both ends of the macroporous carrier tube are sealed with polytetrafluoroethylene plugs, heated in an oven at 150°C for 2 to 4 hours, and then quickly immersed in the dispersed large functionalized α-Al with a mass concentration of 3wt.%. 2 o 3 In the particle suspension I, after dipping for 20s, take it out at a constant speed, and dry it in an oven at 50°C for 3-6h, and then place it in an oven at 180°C for heating and curing for 3h. Large functionalized α-Al attached to the surface of the carrier tube with absorbent cotton 2 o 3 After the particle is wiped off, it is sealed with a Teflon stopper. After heating in an oven at 80°C for 3 hours, quickly immerse...

Embodiment 2

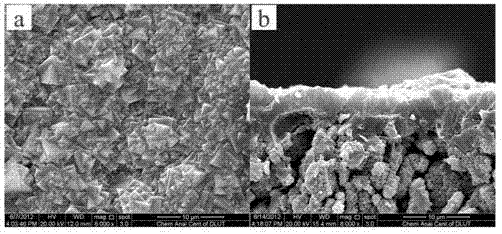

[0037] Microwave heating preparation method of T-type zeolite membrane:

[0038] (1) Preparation of inorganic particle coating

[0039] Same as Example 1, but replace α-Al with pretreated mullite carrier tube 2 o 3 carrier tube.

[0040] (2) T-type zeolite membrane microwave precrystallization

[0041] Weigh 2.683g of NaAlO 2 , 4.945g of NaOH and 3.205g of KOH were dissolved in 19.413g of deionized water. After stirring and clarification at room temperature, 64.841g of silica sol was added dropwise and vigorously stirred at 40°C for 12h. The molar composition was Al 2 o 3 :SiO2 2 :Na 2 O:K 2 O:H 2 O=1:25:6.5:2.25:350. Then, pour the synthesis liquid into the container coated with functionalized α-Al 2 o 3 Microwave crystallization at 100°C for 8h in the microwave reactor of the particle carrier tube. After the reaction is complete, cool to room temperature, take out the membrane tube, wipe off excess T-type zeolite crystals on the surface of the membrane tube, was...

Embodiment 3

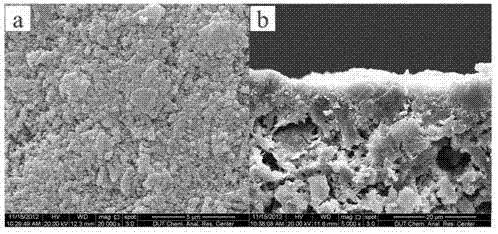

[0046] The pervaporation performance test of the synthesized NaA zeolite membrane and T-type zeolite membrane was carried out using a pervaporation device to characterize the separation performance of the NaA zeolite membrane and T-type zeolite membrane. The composition of the feed liquid is 90wt.% ethanol / water mixed liquid, the temperature is kept at 70°C, and the product on the permeate side is collected with a cold trap. In the experiment, a vacuum pump was used to evacuate the inside of the membrane tube and keep the vacuum at 100-200Pa. Analyze the composition of the permeate product by gas chromatography, calculate the separation coefficient of the zeolite membrane, and calculate the flux of the zeolite membrane by weighing the mass before and after the cold trap. In this experiment, it was measured that the flux of the prepared NaA zeolite membrane was 3.42kg / m 2 h, separation factor > 10000, flux of T-type zeolite membrane is 1.33kg / m 2 h, the separation factor is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com