Method for preparing zinc oxide nanorod-silver microdisk composite heterostructure

A zinc oxide nanorod, heterostructure technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth and other directions, can solve the problem of narrow light absorption range, high charge recombination rate, unfavorable electron and hole acceptors Infiltration and adsorption problems, to achieve the effects of stable product properties, broadened absorption spectrum, and controllable preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

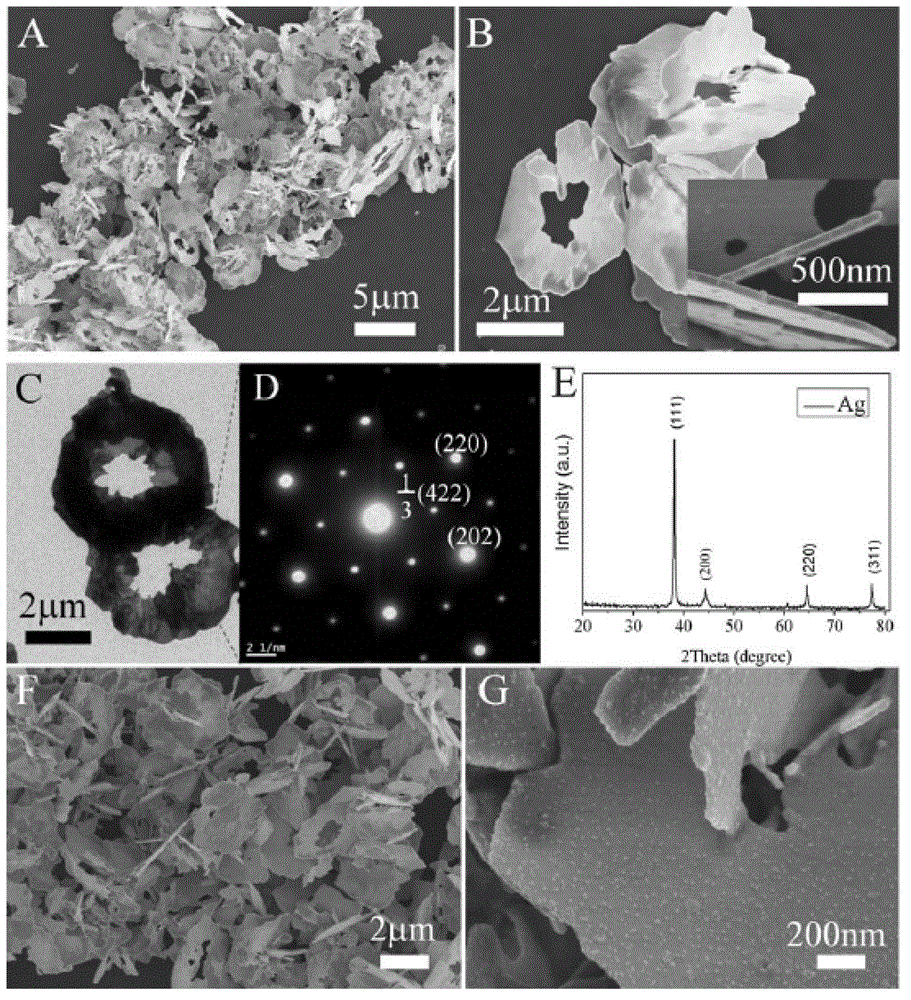

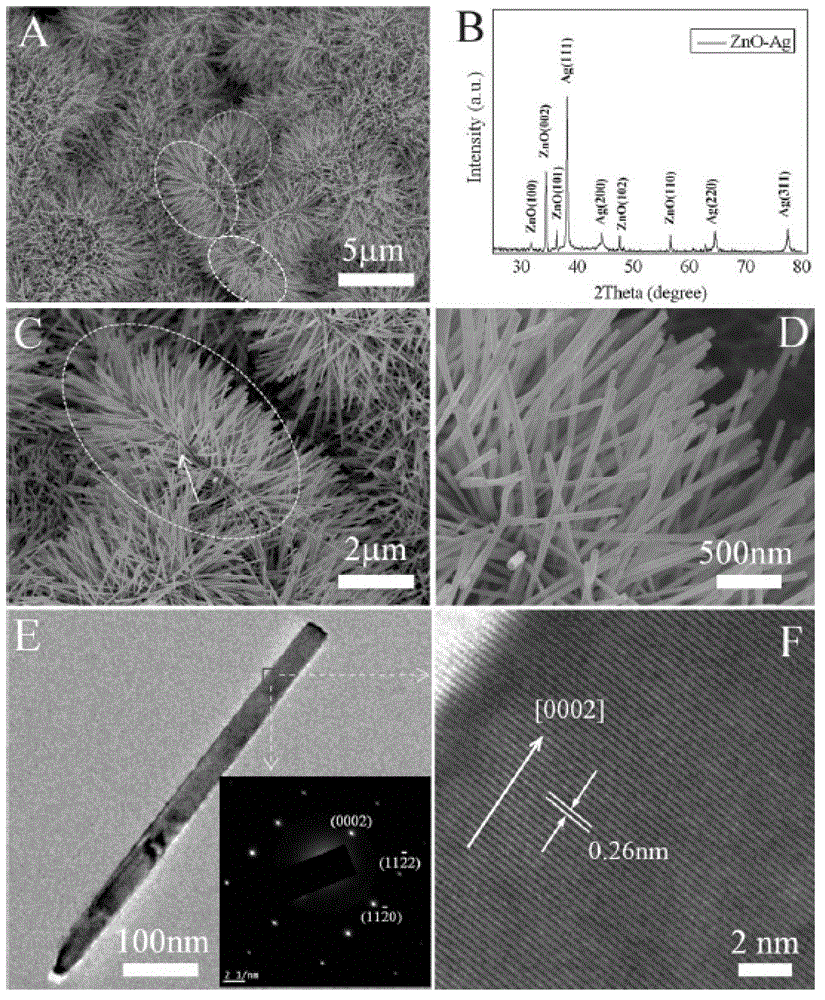

[0028]Weigh 0.1 gram of dextran sodium sulfate (molecular weight 40,000) and dissolve it in the mixed solution of water and formamide, then mix 0.1 milliliter of ascorbic acid and 0.1 milliliter of silver nitrate with equimolar concentration (0.2 mol / liter) successively under stirring Add it into the mixed solution and let it stand at room temperature for 24 hours to prepare a silver microdisc product with holes. The product was centrifuged, washed with water, dried and soaked in 0.1 g / L polyvinylpyrrolidone (PVP, molecular weight 12000) aqueous solution for 4 hours, so that PVP was adsorbed on the silver plate. At the same time, another 125 milliliters of 10 mmol / L zinc acetate in ethanol was added dropwise to 65 mL of 30 mmol / L potassium hydroxide in ethanol, and the mixture was continuously stirred at 60° C. for 2 hours. A zinc oxide seed solution is prepared. Then the silver microdisk that PVP is processed is dispersed in the above-mentioned zinc oxide seed crystal soluti...

Embodiment 2

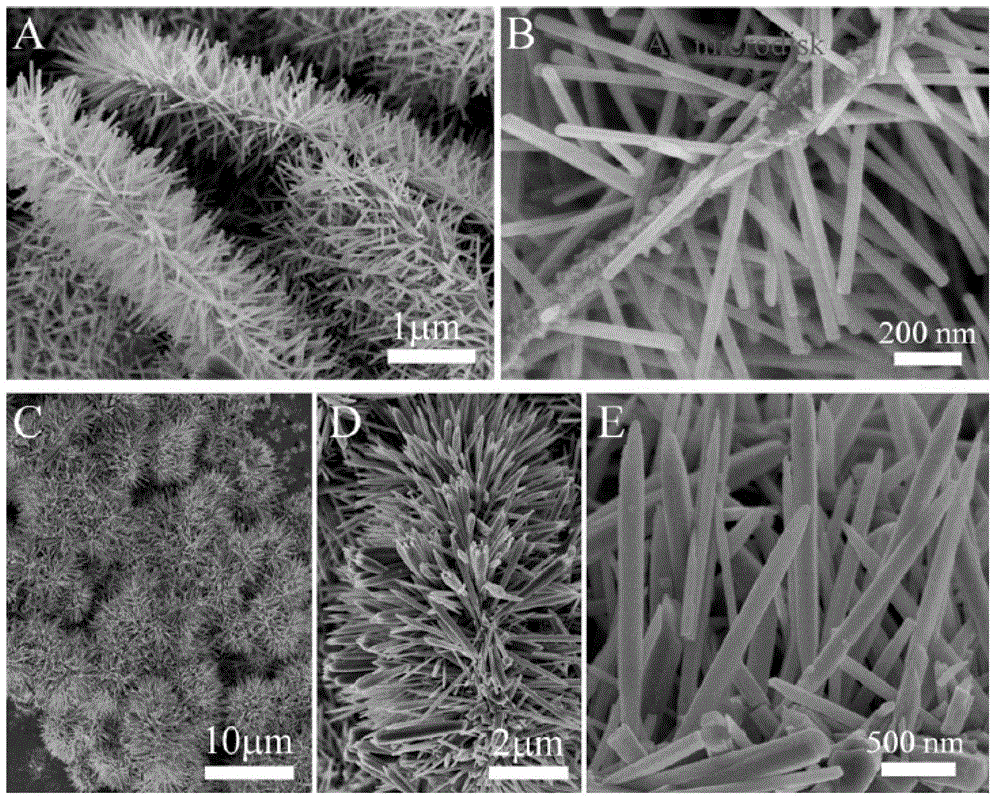

[0030] Weigh 0.1 gram of dextran sodium sulfate (molecular weight 40,000) and dissolve it in the mixed solution of water and formamide, then mix 0.1 milliliter of ascorbic acid and 0.1 milliliter of silver nitrate with equimolar concentration (0.2 mol / liter) successively under stirring Add it into the mixed solution and let it stand at room temperature for 24 hours to prepare a silver microdisc product with holes. The product was centrifuged, washed with water, dried and soaked in 0.1 g / L polyvinylpyrrolidone (PVP, molecular weight 12000) aqueous solution for 4 hours, so that PVP was adsorbed on the silver plate. At the same time, another 125 milliliters of 10 mmol / L zinc acetate in ethanol was added dropwise to 65 mL of 30 mmol / L potassium hydroxide in ethanol, and the mixture was continuously stirred at 60° C. for 2 hours. A zinc oxide seed solution is prepared. Then the PVP-treated silver microdiscs were dispersed into the above-mentioned zinc oxide seed crystal solution, ...

Embodiment 3

[0032] Weigh 0.1 gram of dextran sodium sulfate (molecular weight 40,000) and dissolve it in the mixed solution of water and formamide, then mix 0.1 milliliter of ascorbic acid and 0.1 milliliter of silver nitrate with equimolar concentration (0.2 mol / liter) successively under stirring Add it into the mixed solution and let it stand at room temperature for 24 hours to prepare a silver microdisc product with holes. The product was centrifuged, washed with water, dried and soaked in 0.1 g / L polyvinylpyrrolidone (PVP, molecular weight 12000) aqueous solution for 4 hours, so that PVP was adsorbed on the silver plate. At the same time, another 125 milliliters of 10 mmol / L zinc acetate in ethanol was added dropwise to 65 mL of 30 mmol / L potassium hydroxide in ethanol, and the mixture was continuously stirred at 60° C. for 2 hours. A zinc oxide seed solution is prepared. Then the PVP-treated silver microdiscs were dispersed into the above-mentioned zinc oxide seed crystal solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com