Preparation method of ultra-black coating with nano-pore structure

A nanoporous structure, black coating technology, applied in coating, metal material coating process, liquid chemical plating and other directions, to achieve the effects of good light absorption, reduced reflectivity, and good light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

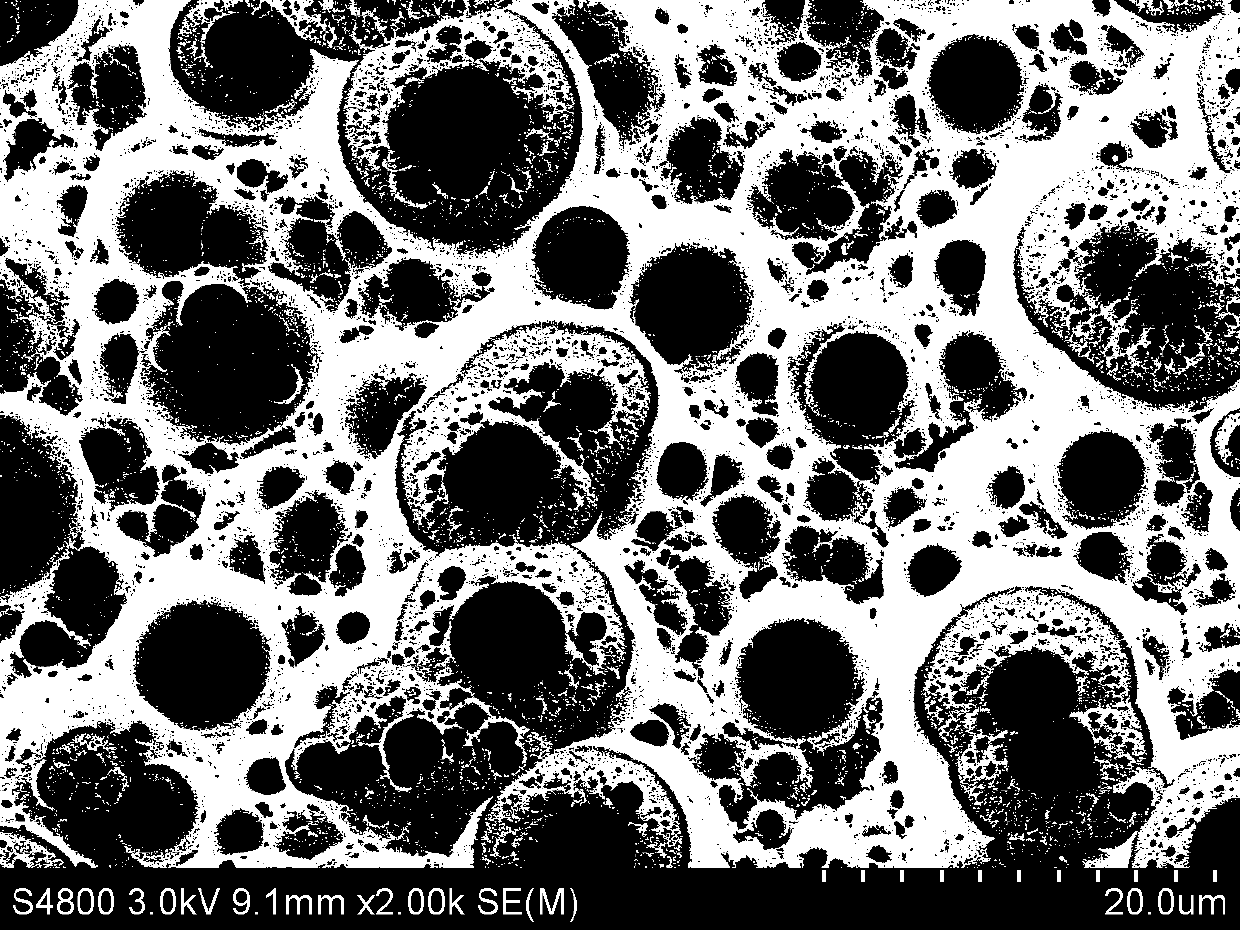

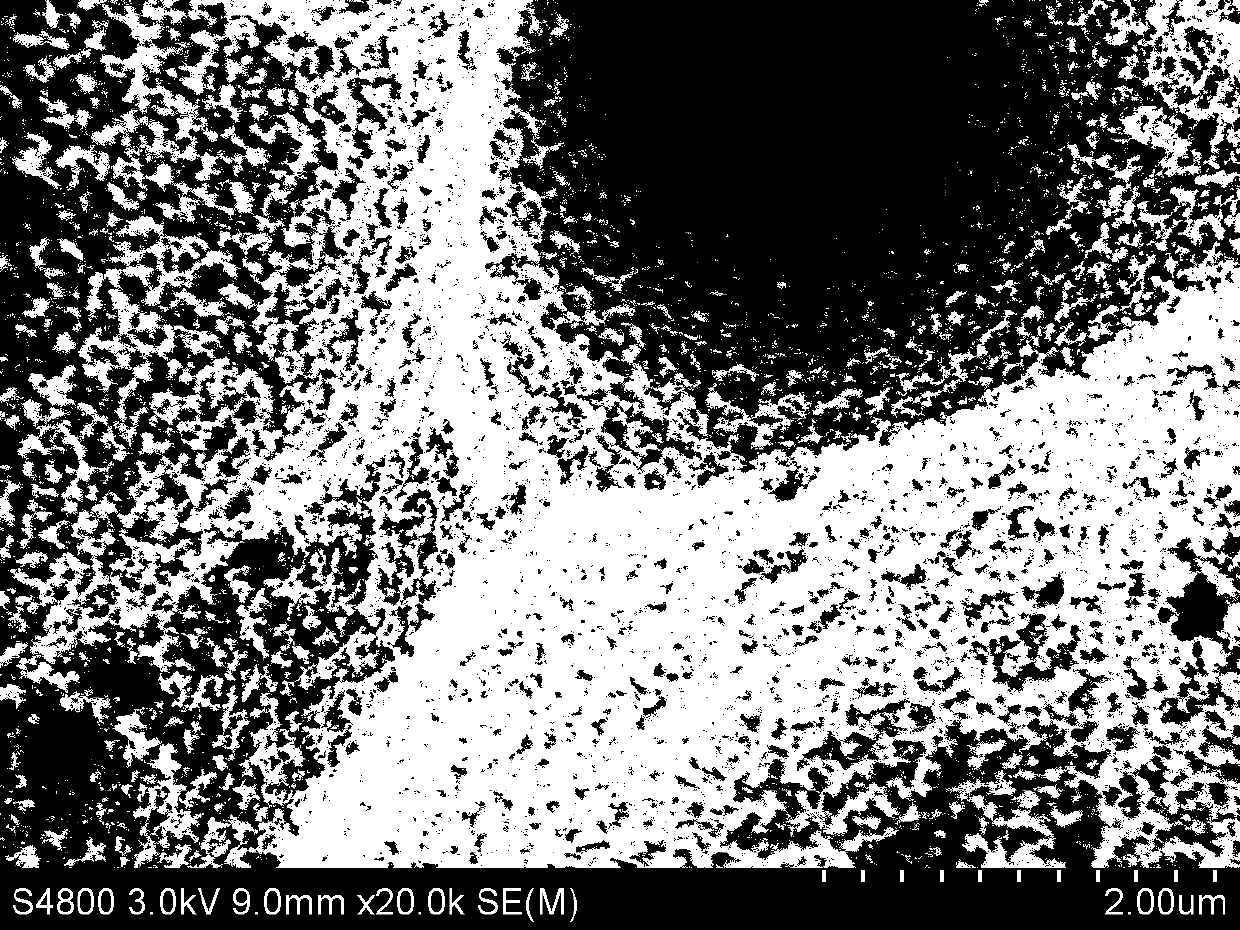

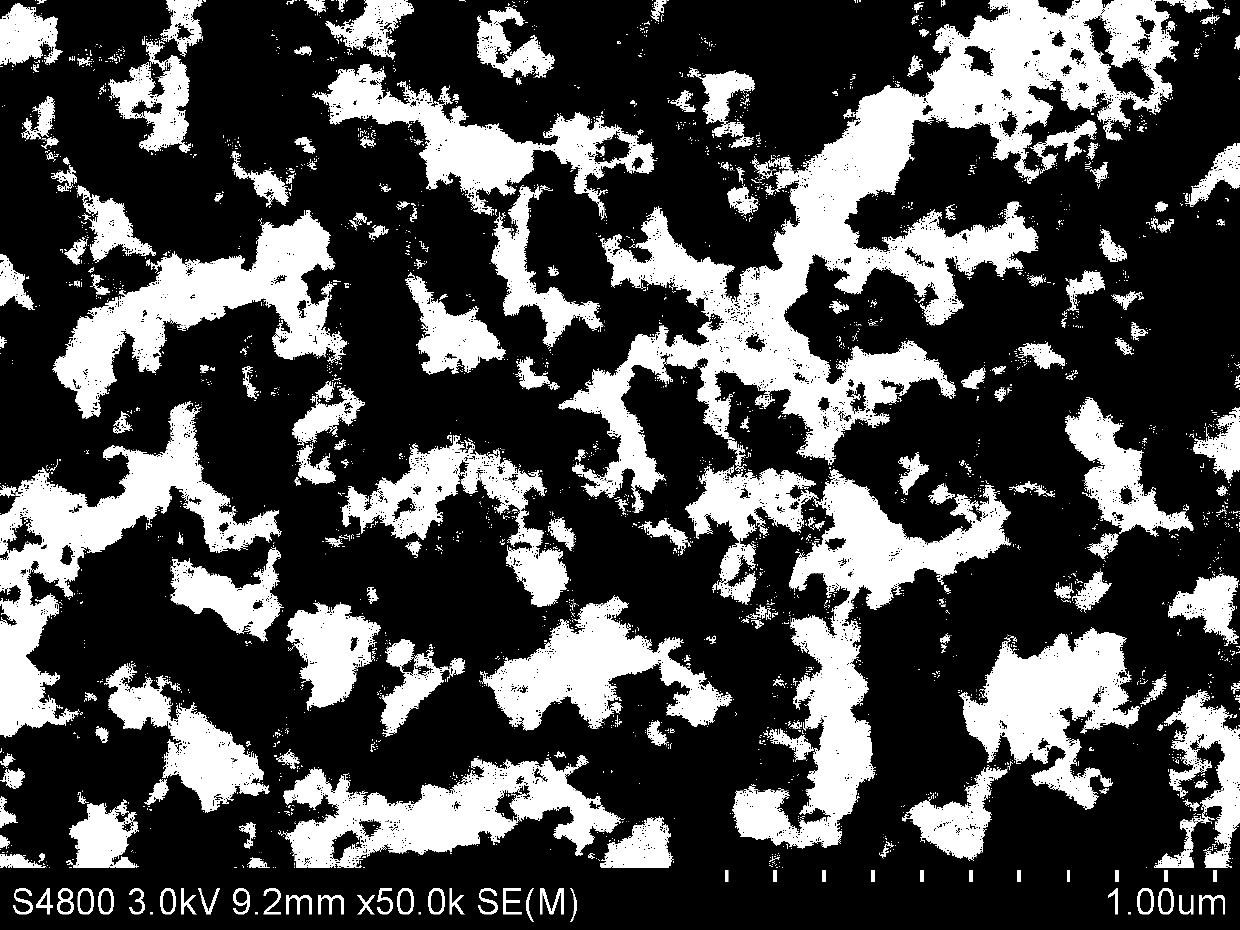

[0031] Use a mixture of 15g / L sodium hydroxide, 40g / L trisodium phosphate and 30g / L sodium carbonate at 40°C to degrease the No. 20 steel substrate (10×10×1.5mm) for 10 minutes, wash with water; then Etch with 5% hydrochloric acid for 2 minutes, wash with water; then put the steel substrate into the electroless plating solution dispersed by ultrasonic vibration for 10 minutes, and plate at 75°C for 3 hours, the pH of the plating solution is 4.5, and the chemical plating solution consists of nickel sulfate 30g / L, Sodium hypophosphite 22g / L, sodium acetate 15g / L, lactic acid 30g / L, carbon black 1.5g / L, solvent is deionized water, carbon black particle size is 20-60nm, wash with water immediately after plating is completed, Dry to obtain a nickel-phosphorus-carbon alloy coating; finally use 6mol / L nitric acid solution to chemically etch the nickel-phosphorus-carbon alloy coating on the surface of the substrate for 90s, wash with water, and dry to obtain an ultra-black coating. fi...

Embodiment 2

[0033] Use a mixture of 40g / L sodium hydroxide, 30g / L trisodium phosphate and 20g / L sodium carbonate at 40°C to degrease the No. 45 steel substrate (20×20×3mm) for 20 minutes, wash with water; then use Etch with 30% hydrochloric acid for 0.5min, wash with water; then put the steel substrate into the electroless plating solution dispersed by ultrasonic vibration for 30min and apply plating at 82°C for 2h, the pH of the plating solution is 3, and the chemical plating solution consists of nickel sulfate 40g / L, Sodium hypophosphite 28g / L, acetic acid 20g / L, lactic acid 30g / L, carbon black 3g / L, the solvent is deionized water, and the particle size of carbon black is 20-60nm. After the plating is completed, it is washed with water immediately and dried. A nickel-phosphorus-carbon alloy coating was obtained; finally, the nickel-phosphorus-carbon alloy coating on the surface of the substrate was chemically etched for 40 seconds with 8 mol / L nitric acid solution, washed with water, and...

Embodiment 3

[0035]Soak the QAl7 aluminum bronze alloy substrate (20×20×3mm) in acetone at room temperature for degreasing for 30 minutes, then wash with water; then etch with 8% sulfuric acid for 1 minute at room temperature, and wash with water; Plating was carried out at 85°C for 1.5 h in the oscillating and dispersed electroless plating solution. The pH of the plating solution was 5.2. Carbon black is composed of 0.5g / L, the solvent is distilled water, and the particle size of carbon black is 20-60nm. After the plating is completed, it is washed with water immediately and dried to obtain a nickel-phosphorus-carbon alloy coating; The nickel-phosphorus-carbon alloy coating was chemically etched for 20s, washed with water, and dried to obtain an ultra-black coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com