Method for preparing monodisperse mesoporous bioactive glass microspheres through template method

A bioactive glass, monodisperse technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems that are not suitable for the preparation of MBGs microspheres, and achieve comprehensive excellent comprehensive performance, high thermal stability and comprehensive performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of 75S25C mesoporous bioactive glass microspheres (M75S25C) with different particle sizes:

[0041] (1) Add 1.8 g of non-polar triblock copolymer Pluronic F127 (hereinafter referred to as F127) to a mixture of 0.04 g of nitric acid solution (2mol / L), 0.1 g of deionized water and 4 g of absolute ethanol, and stir , to obtain a clear mixed solution.

[0042] (2) Add 0.59 g calcium nitrate tetrahydrate to the above mixed solution and stir until completely dissolved.

[0043] (3) Add 1.56 g tetraethyl orthosilicate and continue stirring for 2 h.

[0044] 1) Mix inorganic acid with deionized water and absolute ethanol, add surfactant, stir to obtain a clear mixed solution;

[0045] 2) Add alkali metal or alkaline earth metal source, calcium source, and iron source to the above mixture, stir until completely dissolved, then add silicon source and phosphorus source, and continue stirring;

[0046] The silicon source is tetraethyl orthosilicate (TEOS); the pho...

Embodiment 2

[0055] 1. Preparation of 70S7F magnetic mesoporous bioactive glass microspheres (MM70S7F) with different particle sizes:

[0056] (1) Add 1.8 g of F127 into the mixture of 0.04 g of nitric acid solution (2mol / L) and 4 g of absolute ethanol, and stir until clear.

[0057] (2) Add 0.59 g calcium nitrate tetrahydrate and 0.3 g ferric nitrate nonahydrate and stir until completely dissolved.

[0058] (3) Add 1.56 g tetraethyl orthosilicate and continue stirring for 2 h.

[0059] (4) Four copies of the above solution were prepared in parallel.

[0060] (5) Immerse three-dimensionally ordered macroporous polystyrene / carbon templates with pore diameters of 470 nm, 390 nm, 250 nm, and 180 nm, respectively, and soak overnight.

[0061] (6) Place in an oven at 60°C, and gel the sol for 3 days until it is completely dry.

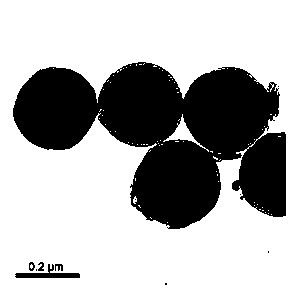

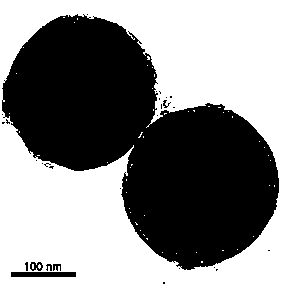

[0062] (7) Remove excess gel on the surface of the template, calcinate in a high-temperature furnace at 600°C for 3 h, grind and ultrasonically disperse to obtain mo...

Embodiment example 3

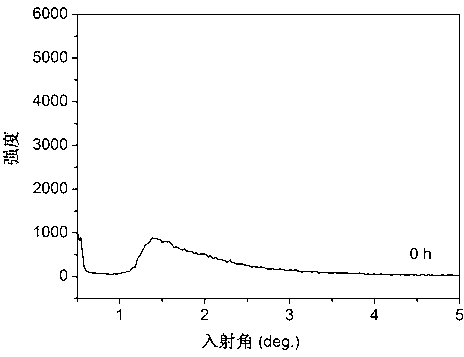

[0088] Preparation and in vitro degradation experiments of 70S30C mesoporous bioactive glass microspheres (M70S30C) with different particle sizes:

[0089] Preparation of M70S30C:

[0090] (1) Add 1.8 g of F127 into the mixture of 0.04 g of nitric acid solution (2mol / L), 0.1 g of deionized water and 4 g of absolute ethanol, and stir until clear.

[0091] (2) Add 0.71 g of calcium nitrate tetrahydrate and stir until completely dissolved.

[0092] (3) Add 1.45 g tetraethyl orthosilicate and continue stirring for 2 h.

[0093] (4) Four copies of the above solution were prepared in parallel.

[0094] (5) Immerse three-dimensionally ordered macroporous polystyrene / carbon templates with pore diameters of 470 nm, 390 nm, 250 nm, and 180 nm, respectively, and soak overnight.

[0095] (6) Place in an oven at 60°C, and gel the sol for 3 days until it is completely dry.

[0096] (7) Remove excess gel on the surface of the template, calcinate in a high-temperature furnace at 600°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com