Highly-doped ZnO:Co magnetic semiconductor film material and preparation method thereof

A technology for magnetic semiconductor and thin film materials, which is applied in the fields of information technology and spintronic materials, can solve the problems of low solid solubility of 3d transition metal doping, weak ferromagnetism, and reduced application value, etc., and achieves composition and preparation conditions. Precisely controllable, high vacuum, ensuring precise control and repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

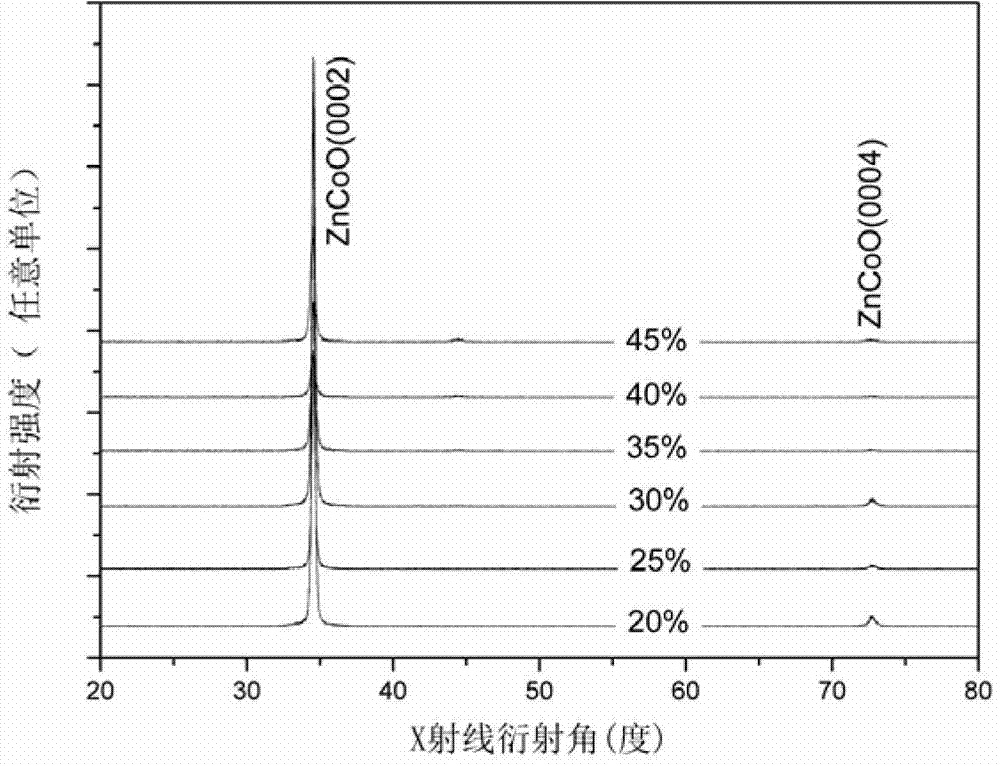

[0052] Example 1: Zn 1-x co x Epitaxial preparation of O magnetic semiconductor film (x=0.20) and its room temperature ferromagnetism.

[0053] (1) Single crystal Al 2 o 3 (0001) Substrate pretreatment:

[0054] Select commercially purchased single crystal Al 2 o 3 (0001) substrates were ultrasonically cleaned in acetone, alcohol, and deionized water for 5 minutes, and dried with high-purity nitrogen. The substrate was first heated to 800°C for 30 minutes and annealed in a vacuum chamber, then cooled to room temperature; high-purity oxygen (purity 99.9995%) was passed through, the oxygen plasma source was ignited, and the substrate was heated to 800°C for 30 minutes for annealing. The background vacuum degree of molecular beam epitaxy vacuum chamber is 1~2×10 -9 mbar, the power of the oxygen plasma source is 350 watts, and the partial pressure of oxygen during operation is 3x10 -5 mbar.

[0055] (2) Preparation of low temperature ZnO buffer layer

[0056] The tempera...

Embodiment 2

[0059] Example 2: Zn 1-x co x Epitaxial preparation of O magnetic semiconductor film (x=0.25) and its room temperature ferromagnetism.

[0060] (1) Carry out single crystal Al by the method of embodiment 1 step (1) 2 o 3 (0001) Pretreatment of the substrate.

[0061] (2) Prepare the low-temperature ZnO buffer layer according to the method of step (2) of Example 1

[0062] (3) Continue to lower the substrate temperature to 400°C, and at the same time start the cold trap in the vacuum chamber of the growth chamber. By passing liquid nitrogen into the cold trap, the oxygen pressure during the growth was reduced to 16×10 -8 Ultra-low pressure of mbar, oxygen plasma source power up to 300 watts. The doping concentration of Co is determined by the relative molecular beam current of Co / Zn, which is measured by an in-situ quartz crystal oscillator. The temperature of the Zn evaporation source is maintained at 330°C, and the temperature of the Co evaporation source is maintained...

Embodiment 3

[0063] Example 3: Zn 1-x co x Epitaxial preparation of O magnetic semiconductor film (x=0.30) and its room temperature ferromagnetism.

[0064] (1) Carry out single crystal Al by the method of embodiment 1 step (1) 2 o 3 (0001) Pretreatment of the substrate.

[0065] (2) Prepare the low-temperature ZnO buffer layer according to the method of step (2) of Example 1

[0066] Continue to lower the substrate temperature to 400 °C, and at the same time start the cold trap in the vacuum chamber of the growth chamber. The oxygen pressure during growth was reduced to 10×10 by passing liquid nitrogen into the cold trap. -8 Ultra-low pressure of mbar, oxygen plasma source power up to 300 watts. The doping concentration of Co is determined by the relative molecular beam current of Co / Zn, which is measured by an in-situ quartz crystal oscillator. The temperature of the Zn evaporation source is maintained at 330°C, and the temperature of the Co evaporation source is maintained at 137...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Source power | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Magnetic moment | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com