Method for preparing diamond-like film by virtue of high-power laser irradiation

A diamond thin film, strong laser technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of immature artificial nano-diamond preparation technology, high diamond preparation cost, unfavorable input into production, etc. The reaction process is safe and controllable, the processing is flexible, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

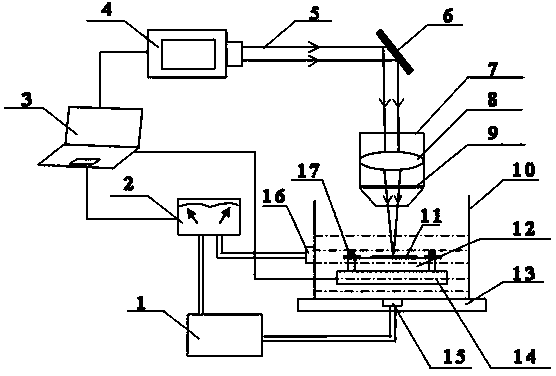

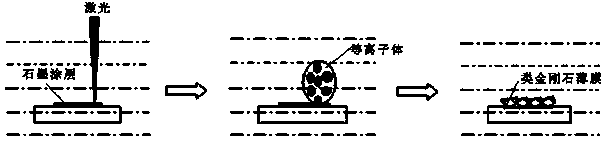

[0020] The surface of the substrate (12) is ground and polished, then cleaned with acetone and alcohol, and dried. The graphite powder is placed in an ultrasonic container filled with alcohol for vibration dispersion, and then the alcohol is evaporated and pre-placed on the surface of the substrate (12) by dipping and pulling method. An appropriate amount of water is passed into the reaction vessel (10), and the substrate (12) is tightened onto the X-Y workbench (14) through the clamp (17). Turn on the power supply of the electric pump (1) to circulate the aqueous solution (18), and the circulation speed is 0.3ml / s. Then turn on the high-power pulse laser device (4), and set the parameters by the computer control system (3), the pulse width is 10ns, the pulse frequency is 10HZ, and the power density is 10 9 W / cm 2 , the spot is a circular spot with a diameter of 6mm and an overlap rate of 50%. The laser light (5) emitted by the high-power pulsed laser device (4) is focused ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com