Vanadium-barium tungstate self-activation luminescent material, preparation methods and application

A luminescent material, barium vanadium tungstate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of high production cost, unstable matrix performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Ba 3 WVO 8.5

[0036] According to the chemical formula Ba 3 WVO 8.5 The stoichiometric ratio of each element in the raw material was weighed separately, barium carbonate BaCO 3 : 1.48 g, ammonium vanadate NH 4 VO 3 : 0.44 g, tungsten oxide WO 3 : 0.58 g, after grinding and mixing in an agate mortar, choose the air atmosphere for the first sintering, the sintering temperature is 300 ° C, the sintering time is 7 hours, then cool to room temperature, take out the sample, repeat the sintering operation, and carry out the second secondary sintering.

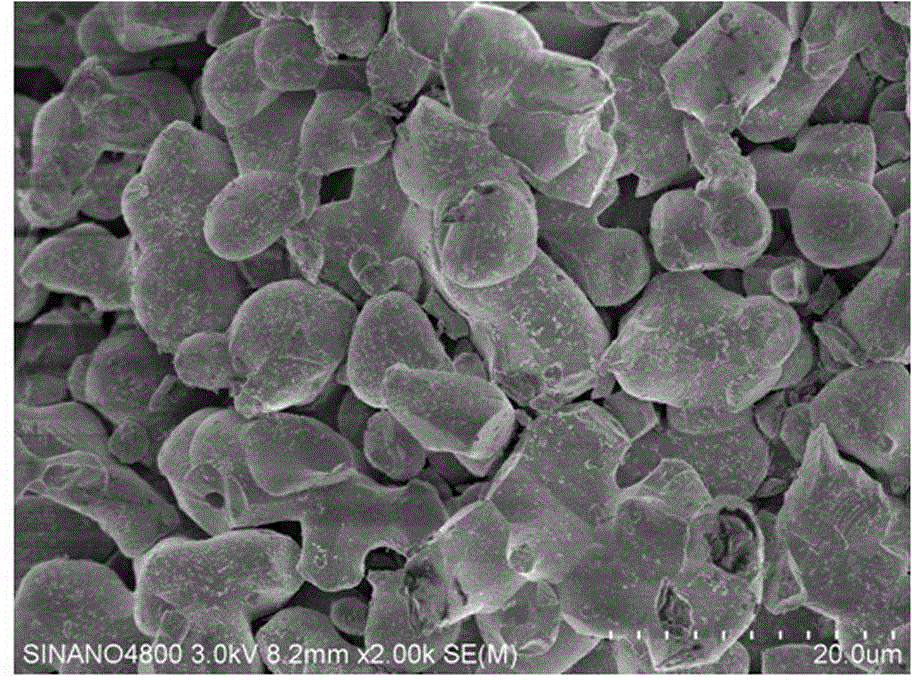

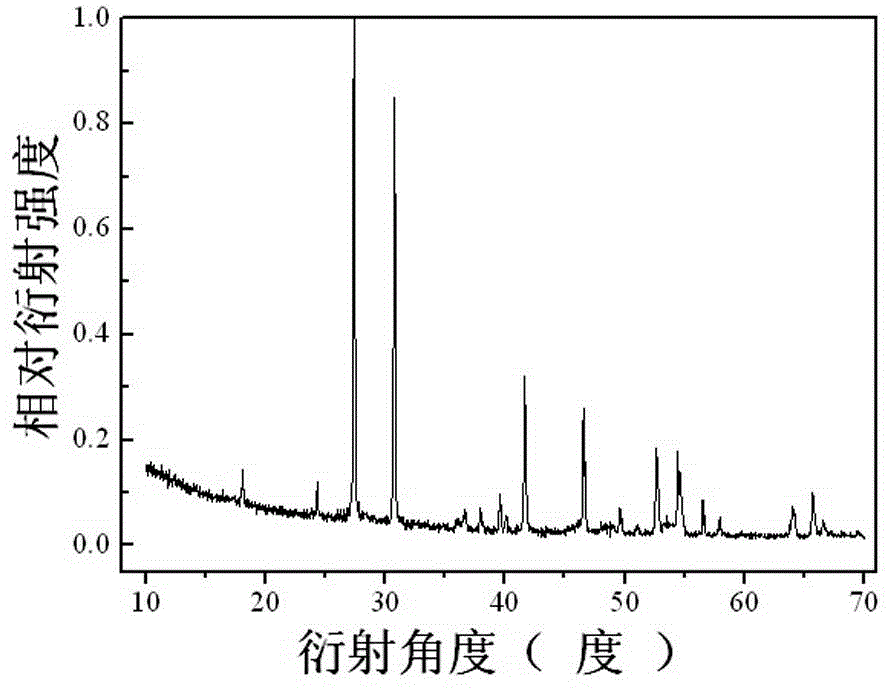

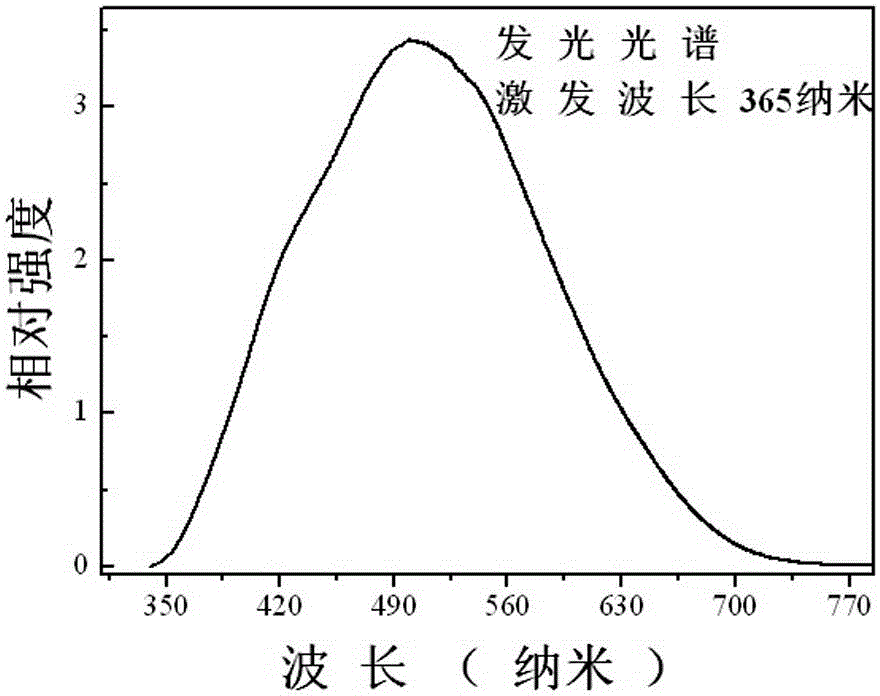

[0037] After the second sintering, the mixture was thoroughly mixed and ground again, and the third calcination was carried out at 700°C in an air atmosphere. The calcination time was 9 hours, cooled to room temperature, and the samples were taken out. Then fully mix and grind the mixture again, and perform the last calcination in the air atmosphere at 1000°C for 8 hours, cool to room temperature, and gr...

Embodiment 2

[0041] Preparation of Ba 3 W 0.5 Mo 0.5 V 0.5 P 0.5 o 8.5

[0042] According to the chemical formula Ba 3 W 0.5 Mo 0.5 V 0.5 P 0.5 o 8.5 The stoichiometric ratio of each element in the raw material was weighed separately, barium carbonate BaCO 3 : 1.48 g, tungsten oxide WO 3 : 0.29 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 -4H 2 O: 0.22 g, ammonium vanadate NH 4 VO 3 : 0.22 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 0.14 g, after grinding and mixing in an agate mortar, select the air atmosphere for the first sintering, the sintering temperature is 450 ° C, the sintering time is 9 hours, then cool to room temperature, take out the sample, repeat the sintering operation, and carry out the second secondary sintering.

[0043] After the second sintering, the mixture was thoroughly mixed and ground evenly, and the third calcination was carried out in an air atmosphere at 900°C for 10 hours, cooled to room temperature, and samples were taken out. Then f...

Embodiment 3

[0046] Preparation of Ba 3 W 0.7 Mo 0.3 V 0.8 P 0.2 o 8.5

[0047] According to the chemical formula Ba 3 W 0.7 Mo 0.3 V 0.8 P 0.2 o 8.5 , respectively weigh barium carbonate BaCO 3 : 1.48 g, tungsten oxide WO 3 : 0.21 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 -4H 2 O: 0.13 g, ammonium vanadate NH 4 VO 3 : 0.35 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 0.06 g, after grinding and mixing in an agate mortar, choose the air atmosphere for pre-sintering, the pre-sintering temperature is 250 ° C, the sintering time is 2 hours, then cool to room temperature, take out the sample; the raw material for the first sintering is again Thoroughly mix and grind evenly, carry out the second sintering in the air atmosphere, the sintering temperature is 900 ° C, the calcination time is 10 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in the muffle furnace, in the air atmosphere Calcining at a temperature of 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com