Special apparatus for removing heavy metal ions in wastewater, and method thereof

A technology of heavy metal ions and special devices, applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve the problems of unreached pollution control effect, secondary pollution, etc., achieve the effect of promoting adsorption, and be easy to process , the effect of inhibiting the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

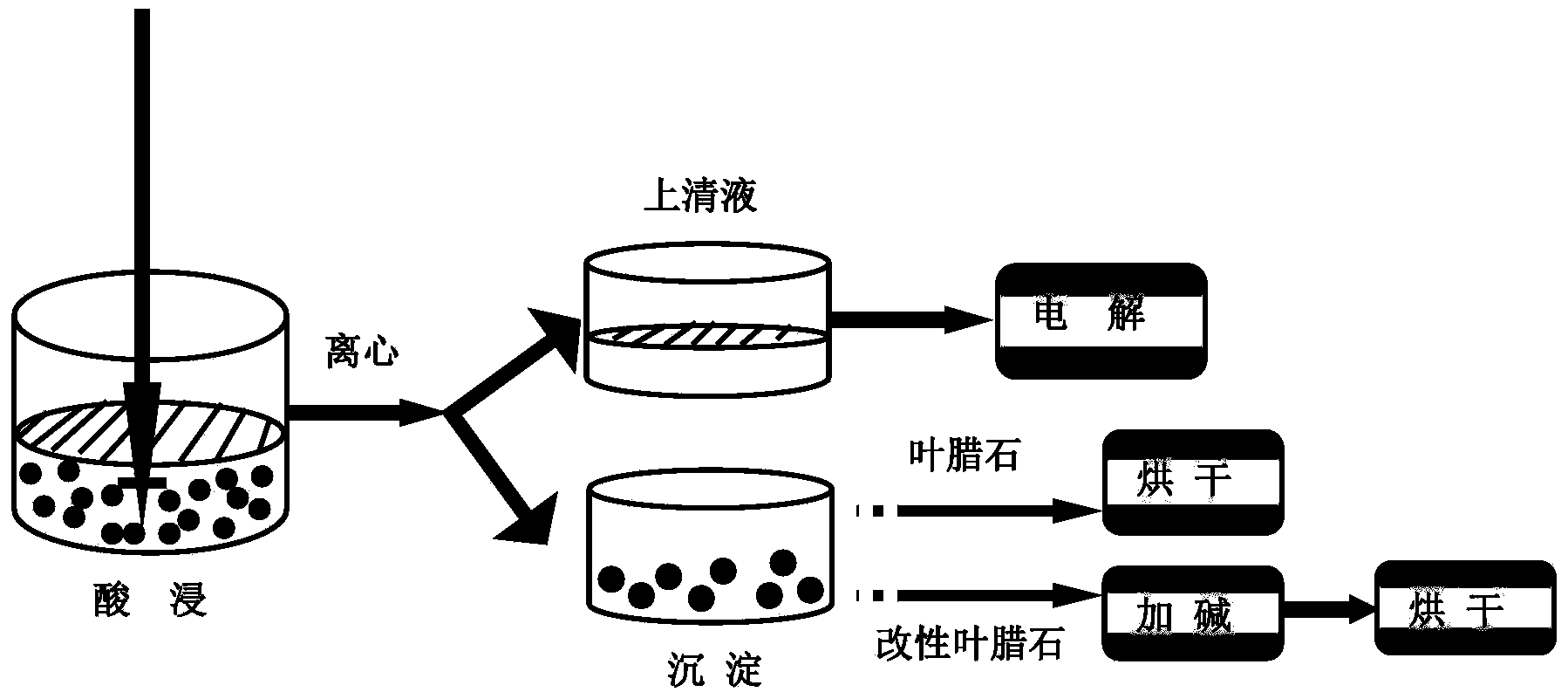

[0040] The preparation of embodiment 1 filler

[0041] The natural pyrophyllite whose particle size range is less than 0.18mm is used as the raw material, and the N-2 (aminoethyl) 3-aminopropylmethyldimethoxysilane coupling agent is used as the modifying agent.

[0042] Add 0.8g of aminosilane coupling agent to a 50ml beaker, then slowly add 0.95g of deionized water dropwise, and stir at room temperature until the solution is uniform and clear to obtain the hydrolyzed product of the silane coupling agent (CH 3 Oh) 2 CH 3 SiC 3 h 6 NHC 2 h 4 NH 2 . Add absolute ethanol with a volume final concentration of 50% to the hydrolyzate for dilution, as a pyrophyllite surface modifier.

[0043] Put pyrophyllite into an agate jar (the milling medium is agate balls), and use a QM-3SP4 planetary ball mill to perform mechanical ball milling at 500r / min (forward and reverse / 5min), and the ball milling time is 6h to obtain pyrophyllite powder; 50g of pyrophyllite powder is pre-dried ...

Embodiment 2

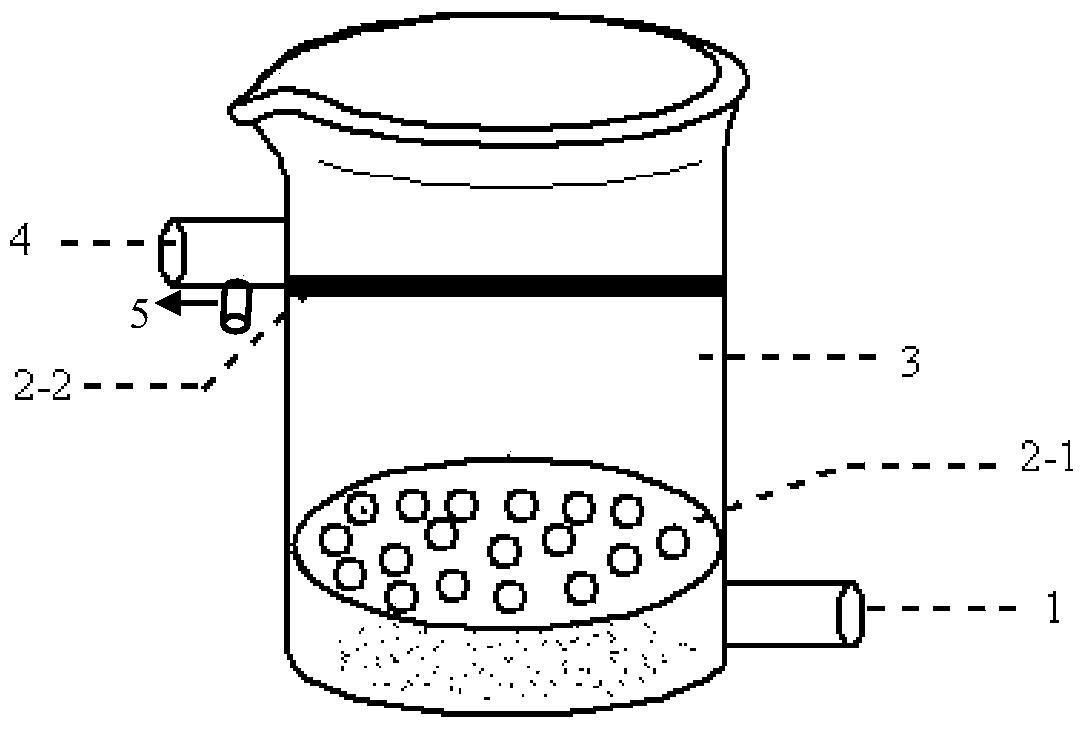

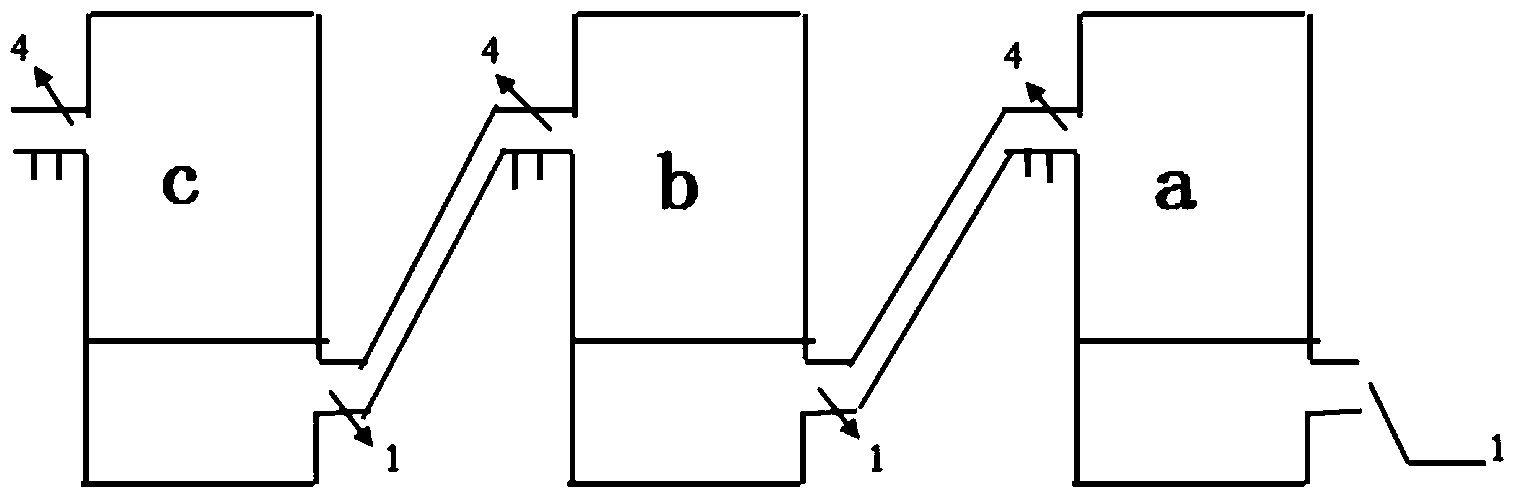

[0049] (1) Special device for wastewater treatment ( figure 2 ): The special device for wastewater treatment is composed of three wastewater treatment equipment units respectively provided with water outlets and water inlets connected in series, the outlet of the former wastewater treatment equipment is connected with the water inlet of the latter wastewater treatment equipment; the wastewater processing equipment unit ( figure 1 ) includes a water inlet 1, a water outlet 4, and a filling chamber 3 (80 mm in height and 55 mm in diameter) is provided inside the waste water treatment equipment unit, the water outlet is located near the upper part of the waste water treatment equipment unit, and the water inlet is located in the waste water treatment unit The equipment unit is close to the lower part. The filling chamber is located at the lower edge of the water outlet and extends to the lower edge of the water inlet. The water quality detection port 5 is provided at the water o...

Embodiment 3

[0060] Wastewater treatment special device and treatment method, adsorbent recovery method are the same as embodiment 2, change waste water into waste water containing 20mg / L, 50mg / L copper ion;

[0061] The metal ion recovery method is the same as that in Example 2, with the copper plate as the cathode and the graphite electrode as the anode, and conduct electrodeposition in a constant temperature water bath at 60°C. After the electrodeposition is complete, wash the cathode (copper plate) with deionized water and absolute ethanol in sequence , dry to obtain elemental copper, and the recovery rate of copper can reach 90%.

[0062] The treatment of the electrolytic solution after the electrolysis and the washing solution after the backwashing of the magnetite filter material is the same as in Example 2, adding a high-concentration sodium hydroxide solution until the precipitation does not separate out to remove iron ions.

[0063] In order to detect the content of copper ions i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com