High temperature resistance polymolecular layer boundary lubrication film for titanium based material surface and preparation method thereof

A multi-molecular layer and boundary lubrication technology, which is applied in the field of material surface friction and wear and solid lubrication, can solve the problems of poor wear resistance, limitation, and large surface friction coefficient, and achieve simple preparation process, low cost, and improved surface wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

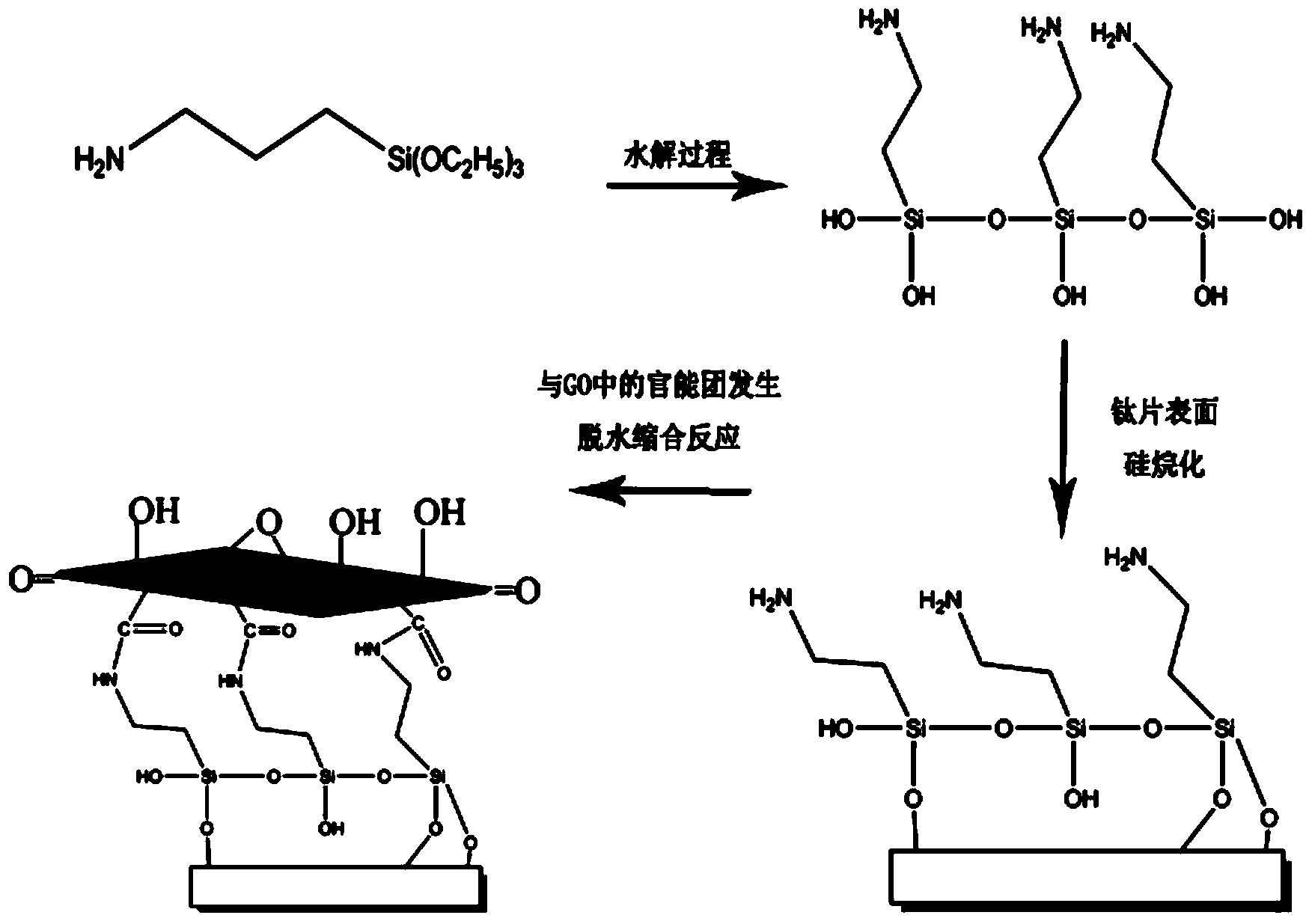

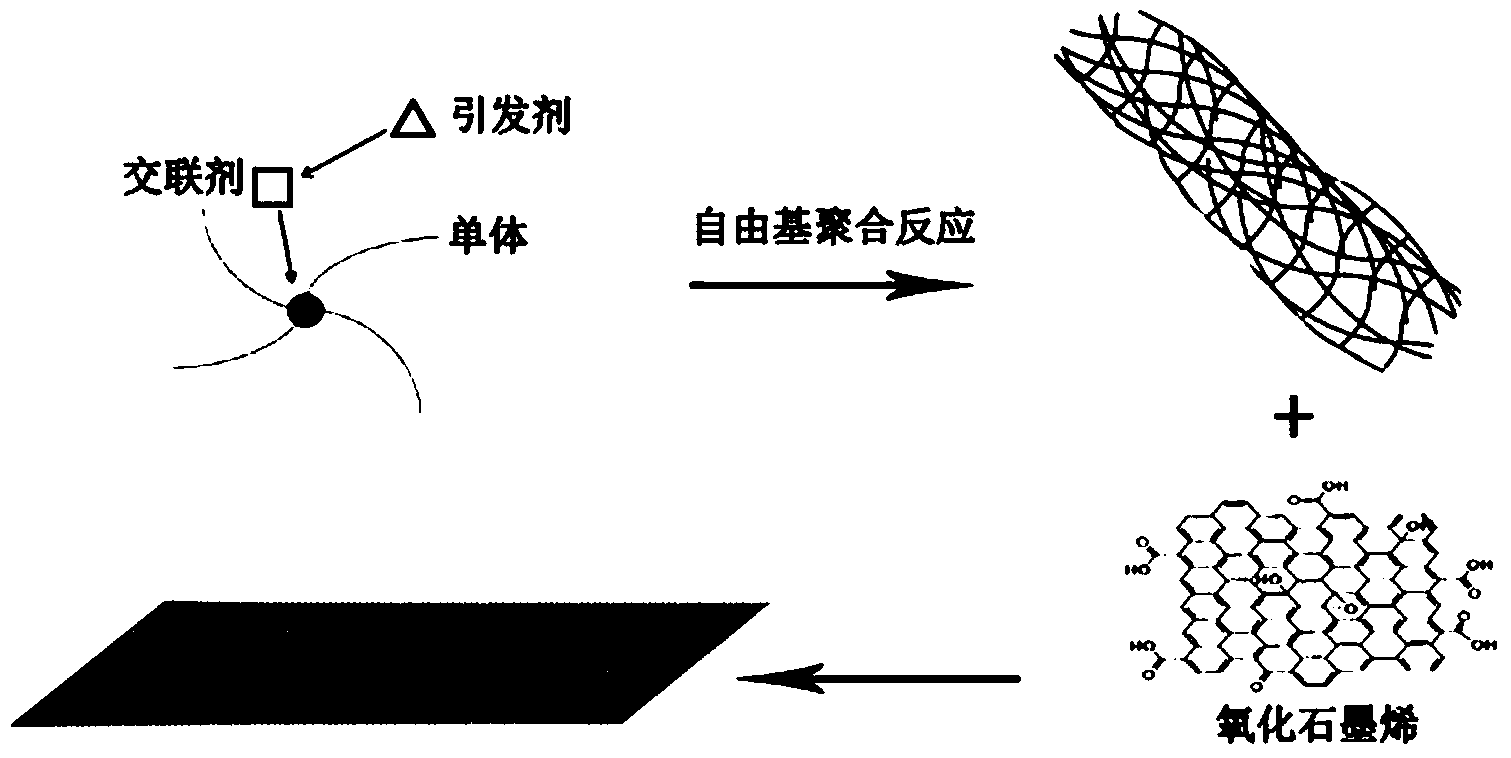

[0027] The essential content of the high temperature resistant multi-molecular layer boundary lubricating film on the surface of the titanium-based material of the invention is to graft hydrogel on the surface of the titanium-based material. The technical route of its preparation method is: pretreatment→surface hydroxylation→grafting graphene oxide nanosheets→grafting hydrogel; after final drying, a high-temperature resistant multi-molecular layer boundary lubricant film can be obtained on the surface of the titanium-based material. Specifically, the steps are as follows:

[0028] Step 1. Grinding and polishing the surface of the titanium-based material until the surface roughness Ra is not greater than 1 μm, cleaning and drying to remove impurities and oil on the surface of the material.

[0029] Step 2: After cleaning and drying, processes such as alkali treatment, anodic oxidation and Piranha solution treatment can be used to make the surface of the titanium-based material ...

Embodiment 1

[0037] The steps of preparing a high temperature resistant multi-molecular layer boundary lubricant film on the surface of pure titanium are as follows:

[0038] Step 1), the pure titanium is ground and polished to a surface roughness Ra of no more than 1 μm, cleaned and dried to remove impurities and oil on the surface.

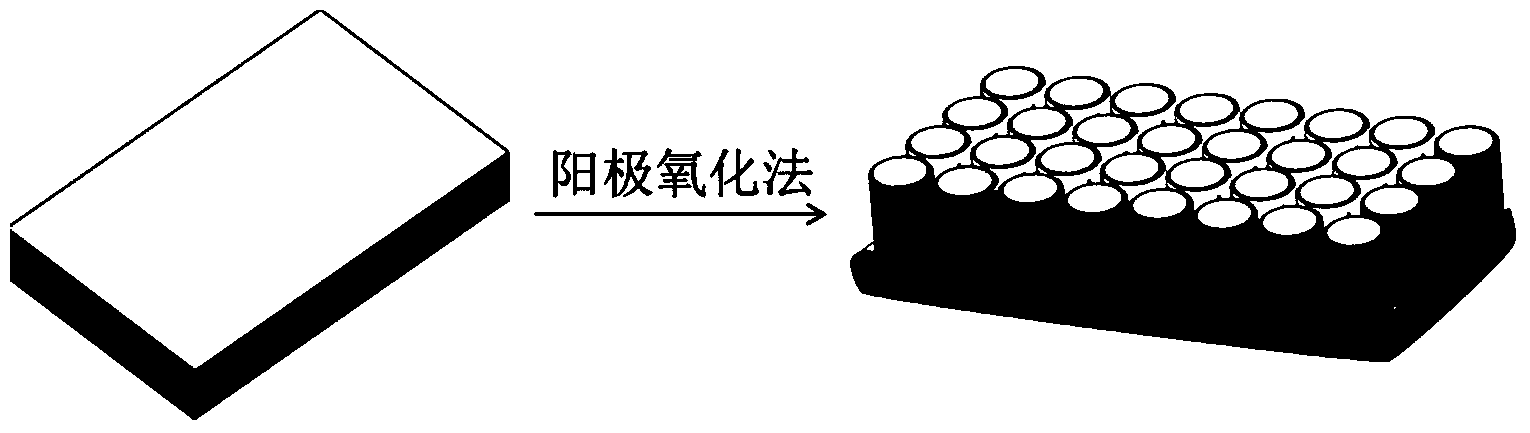

[0039] Step 2), using the anodic oxidation method to prepare TiO with -OH groups on the surface of pure titanium 2 nanotubes, such as figure 1 shown. Electrochemical experiments use a platinum electrode as the cathode and pure titanium as the anode. The electrolyte solution is: ammonium fluoride 0.5wt.%, deionized water 2vol.%, ethylene glycol 98vol.%. The anodic oxidation experiment was carried out in Keithley2400 model constant voltage power supply, the voltage was 40V, and the oxidation reaction time was 3h. The sample whose surface was cleaned and dried was put into the above electrolytic solution. After the reaction was completed, it was ultrasonic...

Embodiment 2

[0046] Embodiment 2: The steps of preparing a high-temperature resistant multi-molecular layer boundary lubricant film on the surface of titanium-zirconium-niobium alloy are as follows:

[0047] Step 1), the titanium-zirconium-niobium alloy is pre-ground and polished to a surface roughness Ra of not greater than 1 μm, cleaned and dried.

[0048] In step 2), the hydrophilic functional group -OH is prepared on the surface of the titanium-zirconium-niobium alloy by alkali treatment. Alkali treatment process: prepare NaOH aqueous solution 5mol L -1 , keeping the previously treated titanium-zirconium-niobium alloy in the above-mentioned NaOH solution at 60-90° C. for 6-8 hours, then taking it out for cleaning and drying.

[0049] Step 3), using aminopropyltrimethoxysilane coupling agent to connect the surface hydroxylated titanium-zirconium-niobium alloy and graphene oxide nanosheets. Prepare the silane coupling agent solution: the concentration of trimethoxysilane coupling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com