Preparation method of lithium ion battery anode material lithium fluoborate

A lithium ferrous borate and lithium-ion battery technology, which is applied in battery electrodes, borates, circuits, etc., can solve the problems that are not conducive to energy conservation and environmental protection, high sintering temperature, poor controllability, etc., and achieve regular shape and high sintering temperature. low cost, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 0.1mol lithium hydroxide, 0.1mol ferric nitrate, 0.025mol ammonium tetraborate and 0.013mol citric acid in 200mL water, stir in a constant temperature water bath at 80°C for 1.5h to obtain a sol, and then stand at this temperature for 0.5h. Make it form a gel, then add water to the original scale of the container to replenish the evaporated water, stir evenly and then spray dry to obtain the precursor. The inlet temperature of the spray drying process is 220°C, the outlet temperature is 130°C, and the feed rate is 1000mL h -1 ; Then place the precursor in a magnetic boat for compaction, put it in a tubular sintering furnace and sinter at 300°C for 2h under the protection of nitrogen, then continue to heat up to 500°C for 10h, and cool naturally to room temperature to obtain LiFeBO 3 .

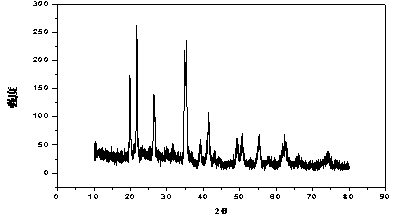

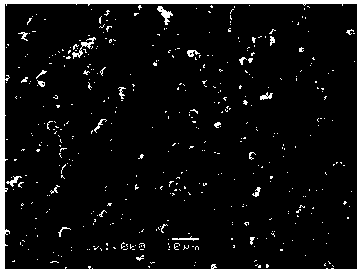

[0026] The XRD diffraction pattern of the sample obtained in this embodiment is shown in figure 1 , the SEM images of the obtained samples are shown in figure 2 . The obta...

Embodiment 2

[0028] Dissolve 0.021mol of lithium acetate, 0.02mol of iron triacetylacetonate, 0.02mol of boric acid, and 0.0075mol of tartaric acid in 200mL of water, stir in a constant temperature water bath at 70°C for 2.5h to obtain a sol, and then stand at this temperature for 0.4h to make it Form a gel, then add water to the original scale of the container to replenish the evaporated water, stir well and then spray dry to obtain the precursor. The inlet temperature of the spray drying process is 220°C, the outlet temperature is 130°C, and the feed rate is 1000mL·h -1 ; Then put the precursor in a magnetic boat for compaction, put it in a tubular sintering furnace and sinter at 300°C for 2.5h under the protection of argon, then continue to heat up to 450°C for 12h, and cool naturally to room temperature to obtain LiFeBO 3 .

[0029] The obtained product is used as the positive electrode material, and the metal lithium sheet is used as the negative electrode material, and assembled into...

Embodiment 3

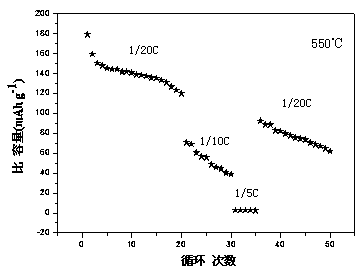

[0031] Dissolve 0.0612mol of lithium nitrate, 0.06mol of ferrous oxalate, 0.03mol of diboron trioxide, and 0.015mol of oxalic acid in 200mL of water, stir in a constant temperature water bath at 80°C for 2h to obtain a sol, and then stand at this temperature for 0.5h , to make it form a gel, then add water to the original scale of the container to replenish the evaporated water, stir evenly and then spray dry to obtain the precursor, the inlet temperature of the spray drying process is 220°C, the outlet temperature is 130°C, and the feed rate is 1000mL·h -1 ; Then put the precursor in a magnetic boat for compaction, put it in a tubular sintering furnace and sinter at 350°C for 2h under the protection of argon, then continue to heat up to 550°C for 5h, and cool naturally to room temperature to obtain LiFeBO 3 .

[0032] The obtained product is used as the positive electrode material, and the metal lithium sheet is used as the negative electrode material, and assembled into a C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com