High-temperature compost decay-promoting bacterial compound inoculant and applications thereof

A kind of bacterial agent and composting technology, applied in the direction of application, bacteria, organic fertilizer, etc., can solve the problems that it is difficult to expect stable effect, fail to achieve expected effect, and does not have the ability to decompose key components of lignocellulose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1, the preparation of bacterial agent

[0068] 1. Experimental materials

[0069] 1. Prepare all bacterial strains

[0070] Bacteria No. 1: Clostridium thermocellum (Clostridium thermocellum) ACCC00165 (ACCC China Agricultural Microorganism Culture Collection Management Center, strain preservation number: 00165);

[0071] Bacteria No. 2: Geobacillus thermophilus (Geobacillus thermophilus) ACCC10253 (ACCC China Agricultural Microorganism Culture Collection Management Center, strain preservation number: 10253);

[0072] Bacteria No. 3: Pseudoxanthomonas taiwanensis CGMCC No1.10867 (CGMCC China General Microorganism Culture Collection Management Center, strain catalog number: 1.10867);

[0073] Bacteria No. 4: Brevibacillus agri (Brevibacillus agri) CGMCC No1.3103 (CGMCC China General Microorganism Culture Collection Management Center, strain catalog number: 1.3103);

[0074] Bacteria No. 5: Bacillus licheniformis (Bacillus licheniformis) CGMCC No1.813 (CGMCC...

Embodiment 2

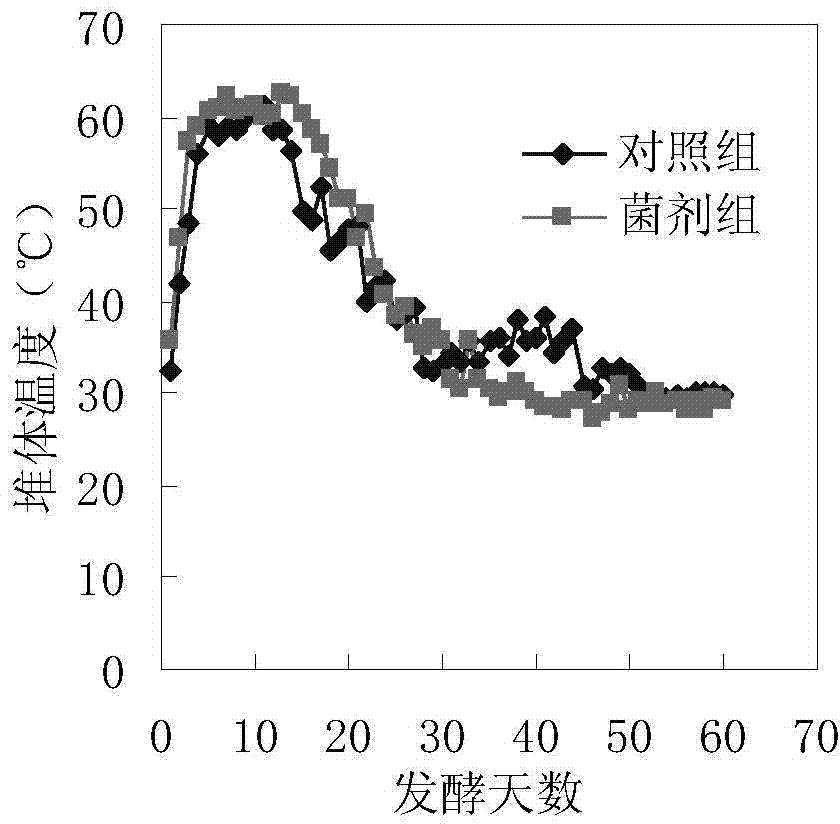

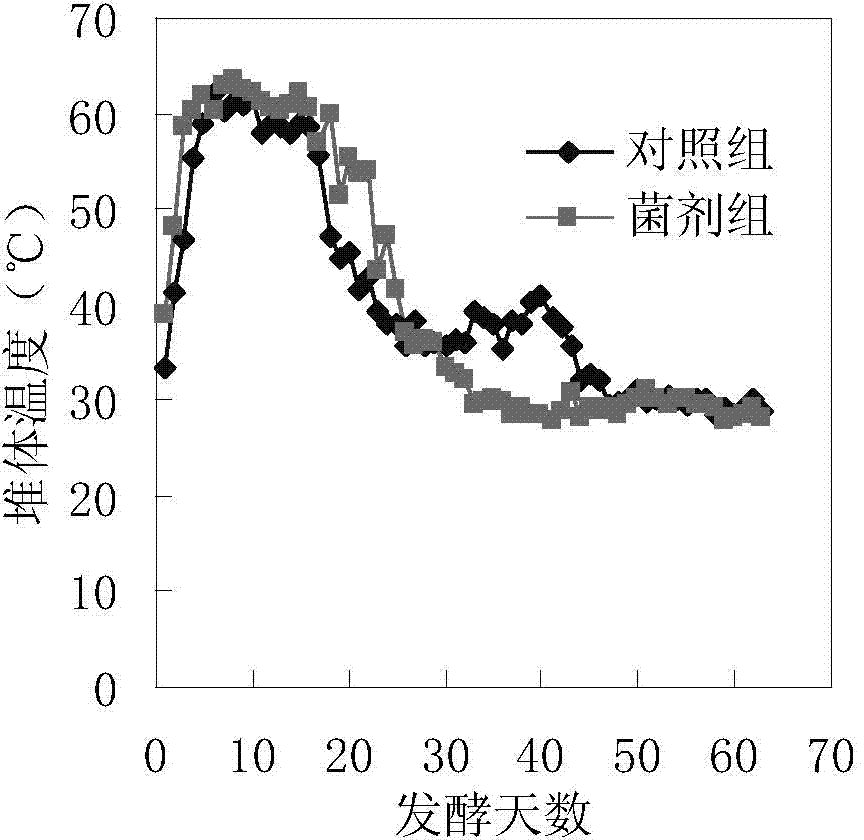

[0124] Embodiment 2, take the edible fungus chaff as main raw material composting composting

[0125] 1. High temperature composting

[0126] Compost raw materials: mixed with fungal chaff, urea, calcium carbonate and water; the mass ratio of fungal chaff, urea and calcium carbonate is 98:1:0.1, and the mass fraction of water is 56%. Wherein, the fungus chaff is the waste culture substrate left after the fungus production in Sanchakou Village, Sanchakou Town, Dongning County, Heilongjiang Province (it can also be the chaff of mushrooms, oyster mushrooms, Agaricus bisporus, Flammulina velutipes, Pleurotus eryngii, etc. ), obtained by removing the plastic skin and crushing into natural particles.

[0127] Mix the bacterial agent prepared in Example 1 and the compost raw material according to the mass ratio of 0.2:100, and make a pile with a width of 3m, a height of 1.3m, and a length of 20m. During the stacking process, the temperature of the stack body is regularly monitored ...

Embodiment 3

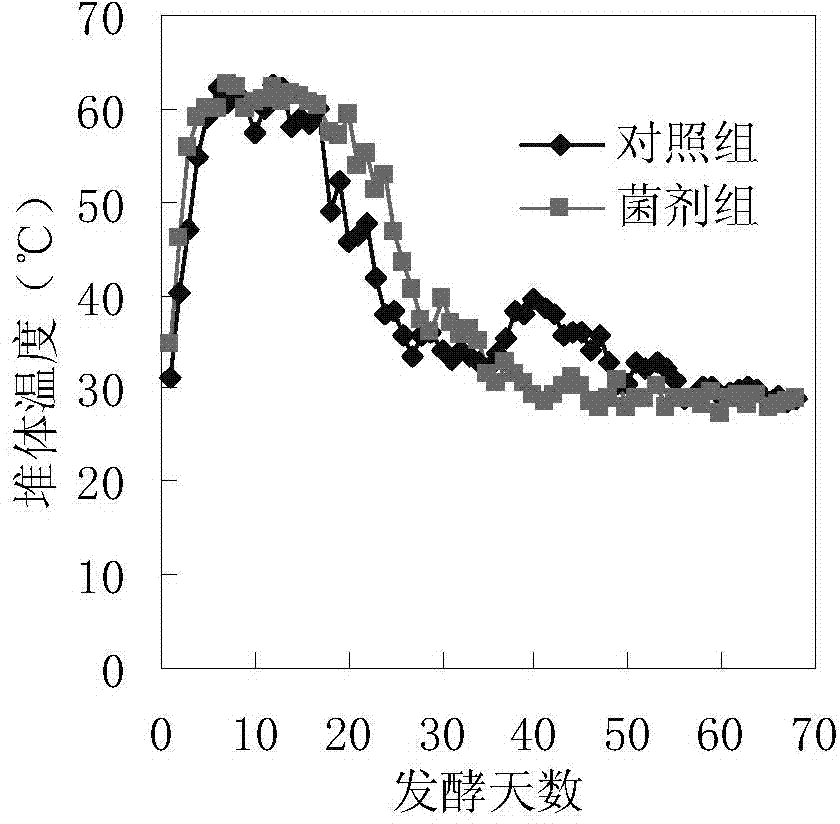

[0158] Embodiment 3, composting with livestock and poultry manure as main raw material

[0159] 1. High temperature stacking

[0160] Compost raw materials: It is made of cow dung, straw, returned material and water; the mass ratio of cow dung, straw and returned material is 80:10:10, and the mass fraction of water is 55%. Wherein, the return material refers to composting the final obtained compost with the initial compost raw material according to the following method; compared with the above-mentioned compost raw material, the initial compost raw material only lacks the return material, and the rest of the composition is the same. The straw is corn straw (rice straw, wheat straw, rape straw, sweet potato vine, tobacco straw, flower and grass litter, flower and grass mowing, etc. can also be used), with a particle size of 2-5 cm and a moisture content of 16%.

[0161] Mix the bacterial agent prepared in Example 1 with the compost raw material according to the mass ratio of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com