Wine yeast with low yield of higher alcohol

A technology of wine yeast and higher alcohol, applied in the field of wine yeast, can solve the problem of high content of higher alcohol, achieve the effect of reducing the content and improving the health value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Breeding of low-yielding high-alcohol wine yeast

[0033] 1) Mutagenesis of the starting strain:

[0034] a. Pick a small amount of yeast cells from the slant of wine yeast EC1118 with an inoculation needle as the starting strain, inoculate it into 20 mL of YPD liquid medium, and culture it with shaking at 30°C for 16-18 hours to obtain the starting strain liquid.

[0035] b. Then take 1mL of the starting strain bacterial solution in a centrifuge tube at 12000r / min, centrifuge for 15s to collect the cells, and wash once with sterile water.

[0036] c. Suspend the cells with 1 mL of sterile sodium phosphate buffer (a mixture of sodium dihydrogen phosphate, disodium hydrogen phosphate and sterile water; the concentration of the buffer is 0.1mol / L) with a pH value of 7.0, and add 30 μL of methanesulfonic acid Ethyl ester (EMS) stock solution, shake to disperse the cells, place in a shaker at 30°C for 1 hour and then centrifuge.

[0037] d. Then add a 5% ste...

Embodiment 2

[0044] Example 2: Analysis of higher alcohol production of the starting strain and the target strain

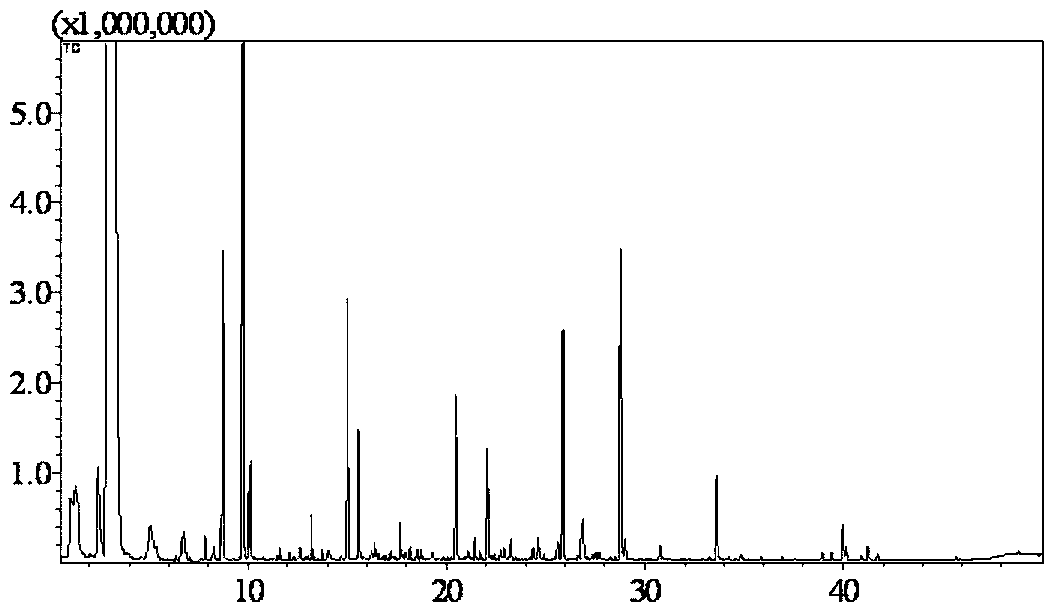

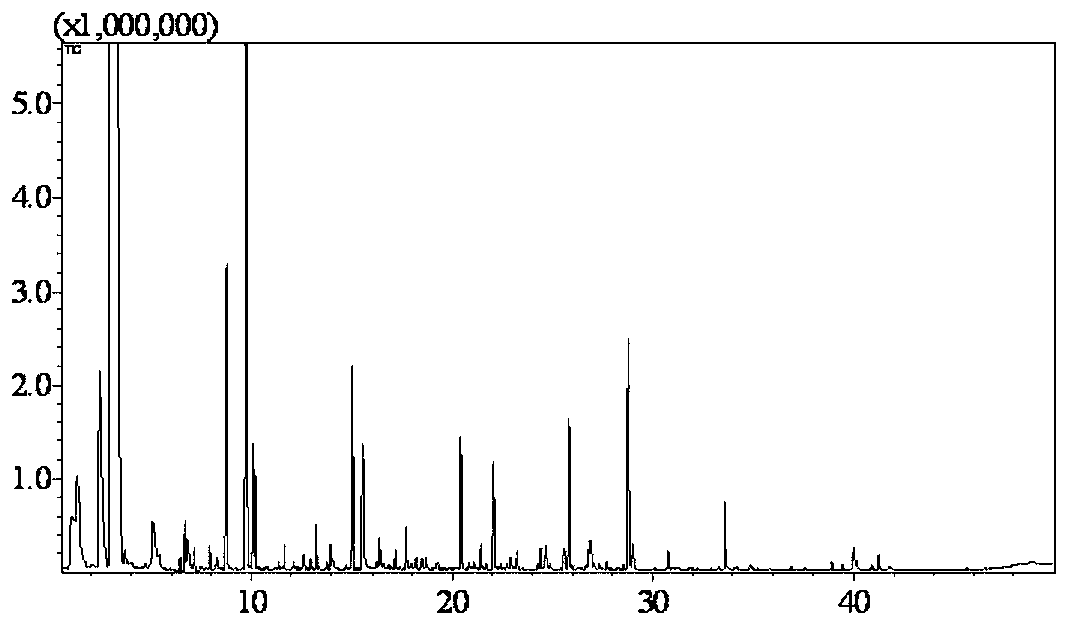

[0045]Extraction of higher alcohols: Accurately measure 8mL of wine fermented by strain CP1118, put it into a 15mL headspace bottle, add 1g NaCl to promote the volatilization of higher alcohols, and then add 30μL of internal standard (4-methyl-2-pentanol) , and immediately seal and compress with a PTFE / silicone rubber septum. When the wine sample temperature reached 45°C, it was extracted with DVB / CAR / PDMS extraction head for 50 minutes, and the sample was injected for gas chromatography-mass spectrometry analysis.

[0046] GC / MS conditions: chromatographic column, Stabilwax-DA capillary column ((30m×0.32mm×0.25μm)); heating program: keep at 30°C for 1min, rise to 100°C at 6°C / min, and raise temperature at 3°C / min To 200°C, raise the temperature to 210°C at 10°C / min, and keep for 3min; the injector temperature is 250°C; the detector temperature is 250°C, splitless injection....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com