Method for producing microbial flocculant by using Paenibacillus mucilaginosus

A technology of microbial flocculant and Bacillus, applied in the field of preparation of microbial polysaccharides, achieves the effects of high purity and activity, shortened process time and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The method for producing microbial flocculant by Paenibacillus colloidus comprises the following process steps:

[0044] A, adopt thermal shock method to carry out strain domestication to Paenibacillus mucilaginosus (Paenibacillus mucilaginosus) ACCC10013;

[0045] B. Paenibacillus colloidus ACCC10013 acclimated in Step A of aerated culture in a sterile fermentation medium containing carbon source, nitrogen source and growth factors to obtain a fermentation broth containing microbial flocculants;

[0046] C. Separating the fermented liquid containing the microbial flocculant prepared in step B by using a macroporous adsorption resin to prepare a microbial flocculant.

[0047] Described step A comprises following processing step:

[0048] A1, under aseptic conditions, add the bacterial species spores in the inclined plane of the test tube to sterile water, shake and wash the spores to make a spore suspension;

[0049]A2. Place the sterile container containing the spore...

Embodiment 2

[0078] The difference between this embodiment and embodiment 1 is:

[0079] The fermentation medium in the described step B consists of the following components in mass percentage:

[0080] Starch 20%, sucrose 10%, ammonium sulfate 2%, dipotassium hydrogen phosphate 2%, ferric chloride 0.5%, Tween-800.01%, yeast extract 3%, the balance is tap water, pH=7.5.

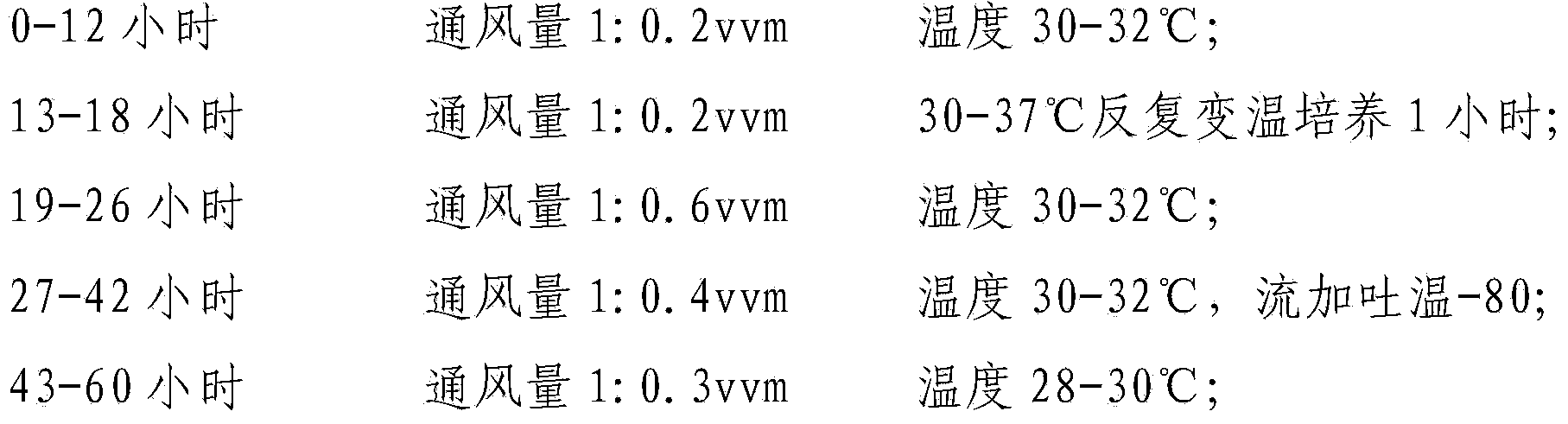

[0081] The culture condition in the described step B is:

[0082]

[0083] The amount of inoculum is the mass ratio of bacterial species: sterile fermentation medium = 4%-8%.

[0084] The preparation of the seed liquid is also included between the steps A and B, wherein the seed culture medium is composed of the following components in mass percentage:

[0085] Starch 5g, dipotassium hydrogen phosphate 5g, peptone 5g, yeast extract 5g, ammonium sulfate 0.5g, magnesium sulfate 0.5g, distilled water 1000ml, agar 18g.

[0086] The macroporous resin in the step C is selected from S-8 macroporous adsorption resin.

[00...

Embodiment 3

[0100] The difference between this embodiment and embodiment 1 is:

[0101] The fermentation medium in the described step B consists of the following components in mass percentage:

[0102] Starch 10%, sucrose 8%, ammonium sulfate 1%, dipotassium hydrogen phosphate 1.5%, ferric chloride 0.2%, Tween-800.005%, yeast extract 1%, the balance is tap water, pH=7.5.

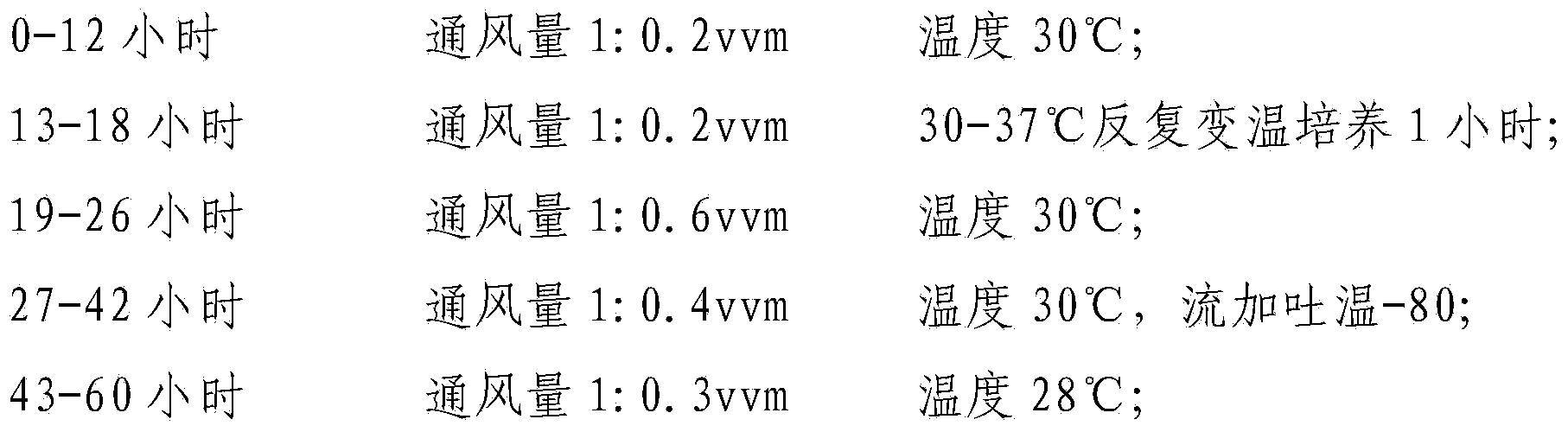

[0103] The culture condition in the described step B is:

[0104]

[0105] The preparation of the seed liquid is also included between the steps A and B, wherein the seed culture medium is composed of the following components in mass percentage:

[0106] Starch 3g, dipotassium hydrogen phosphate 2g, peptone 3g, yeast extract 3g, ammonium sulfate 0.3g, magnesium sulfate 0.3g, distilled water 1000ml, agar 18g.

[0107] The macroporous resin in the step C is selected from S-8 macroporous adsorption resin.

[0108] Adopt macroporous adsorption resin to carry out post-treatment preferred technical scheme to the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com