Synthesis method and application method of medium and low temperature heat-expandable microspheres

A technology of expanded microspheres and synthesis methods, applied in the direction of adhesive types, nitrile copolymer adhesives, coatings, etc., can solve the problems of high investment cost, high equipment requirements, easy rupture of damaged parts, etc. The effect of increasing and decreasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

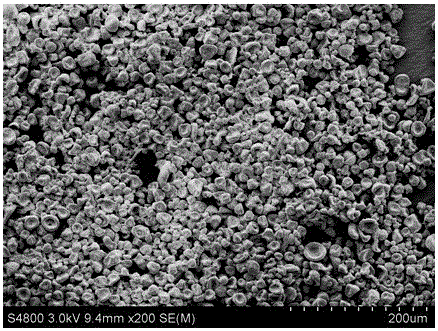

Image

Examples

Embodiment 1

[0059] Add 120g acrylonitrile, 24g methacrylonitrile, 24g methyl methacrylate, 72g ethyl acrylate, 0.4g trimethylolpropane trimethacrylate, 30g isopentane, 0.3g benzoyl peroxide, A suspension polymerized oil phase is obtained.

[0060] Add 300g deionized water, 10g sodium chloride, 8g sodium hydroxide, 14g magnesium chloride hexahydrate successively, after stirring and reacting at room temperature for half an hour, add 3g of sodium lauryl sulfate solution (mass fraction is 1%), obtain The aqueous phase of the polymerization is suspended.

[0061] After mixing the above-mentioned oil phase and water phase, stir with a homogeneous dispersant machine at 7000 rpm in an ice-water bath for 5 minutes to obtain a suspension solution. The suspension solution was injected into a 1.0 L high-pressure reactor, and after the air was replaced by nitrogen, the reactor was pressurized to an initial pressure of 0.3 MPa; then reacted at 60°C for 20 hours. Then lower the temperature, release th...

Embodiment 2-12 and comparative example 1-5

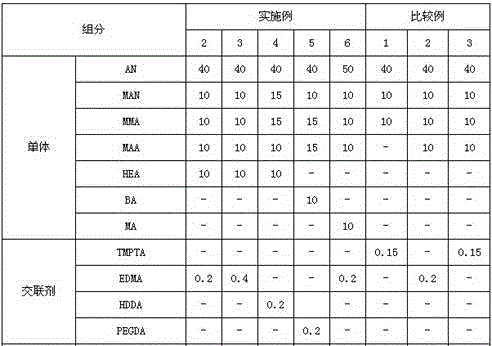

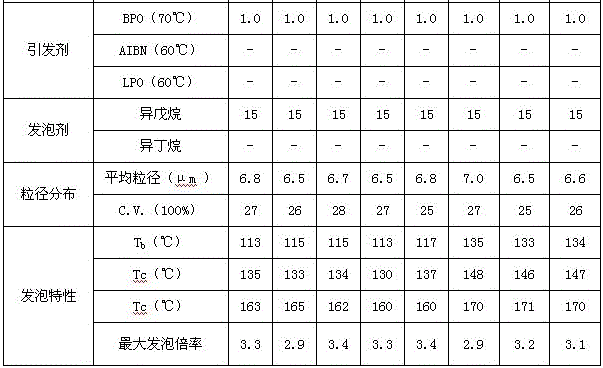

[0064] 1) Using the same synthesis method as in Example 1, each component and reaction temperature are shown in Table 1-2

[0065] In Tables 1 and 2, AN: acrylonitrile, MAN: methacrylonitrile, MAA: methacrylic acid, MMA: methyl methacrylate, BA: butyl acrylate, HEA: 2-hydroxyethyl acrylate, MA: Methyl Acrylate, TMPTA: Trimethylolpropane Trimethacrylate, EDMA: Ethylene Glycol Dimethacrylate, HDDA: 1,6-Hexanediol Diacrylate, PEGDA: Polyethylene Glycol Diacrylate (average molecular weight 500), AIBN: 2,2'-azobisisobutyronitrile, BPO: benzoyl peroxide, LPO: lauroyl peroxide.

[0066] 2) Through the test experiment of particle size distribution characteristics and foaming performance, the thermal expansion microspheres were compared and analyzed

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com