Preparation method of mesoporous material

A mesoporous material and template technology, applied in the field of materials, can solve the problems of reduced enzyme activity, poor stability, loss of activity, etc., and achieve the effects of improved enzyme stability and catalytic activity, mild production reaction conditions, and improved catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: preparation of mesoporous material

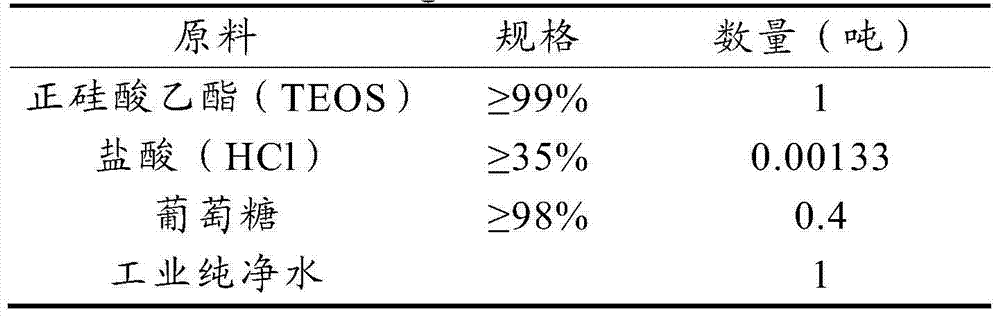

[0047] Table 2. Raw materials required to produce 400kg of mesoporous materials

[0048]

[0049] The preparation process is as follows:

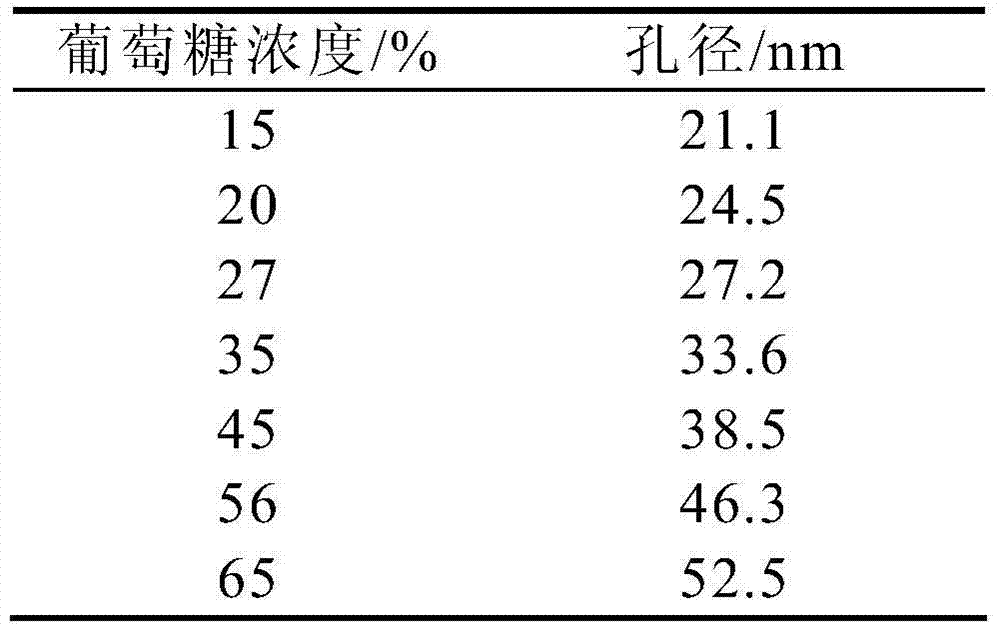

[0050]Ethyl orthosilicate, water, and hydrochloric acid are stirred and mixed in proportion at room temperature to carry out sol-gel reaction. The reaction time is about 15 minutes to obtain a homogeneous colorless and transparent sol, which is cooled with water to fully remove and recover the reaction product. The by-product ethanol forms a pre-hydrolyzed gel, then adds D-glucose or fructose aqueous solution under stirring, and finally adds sodium hydroxide solution to adjust the pH value of the system to near neutral, and then place it at low temperature to form a gel for about 48 hours After the gelation is complete, crush the gel, wash it with water for 2-3 times to remove the glucose template in the gel system, filter and dry the mesoporous material for 2-3 days, and further...

Embodiment 2

[0055] Embodiment 2: Preparation of the mesoporous immobilized enzyme of the present invention

[0056] See Table 3 for the preparation of mesoporous immobilized cellulase as an example.

[0057] table 3

[0058]

[0059] When preparing mesoporous immobilized cellulase, the mass ratio of mesoporous material to enzyme is 4:2.

[0060] One-step preparation of mesoporous immobilized enzymes:

[0061] Referring to Example 1, the step of preparing a mesoporous material to form a pre-hydrolyzed gel, after adding D-glucose aqueous solution under stirring, then adding cellulase buffer in proportion under stirring, and finally adding sodium hydroxide solution to adjust The pH value of the system is near neutral, and then placed in a low temperature environment to form a gel. After the gelation is completed for about 48 hours, the obtained wet gel is ground and pulverized, and washed with water twice to remove the glucose template in the gel system. Filter, dry for 2-3 days, grind...

Embodiment 3

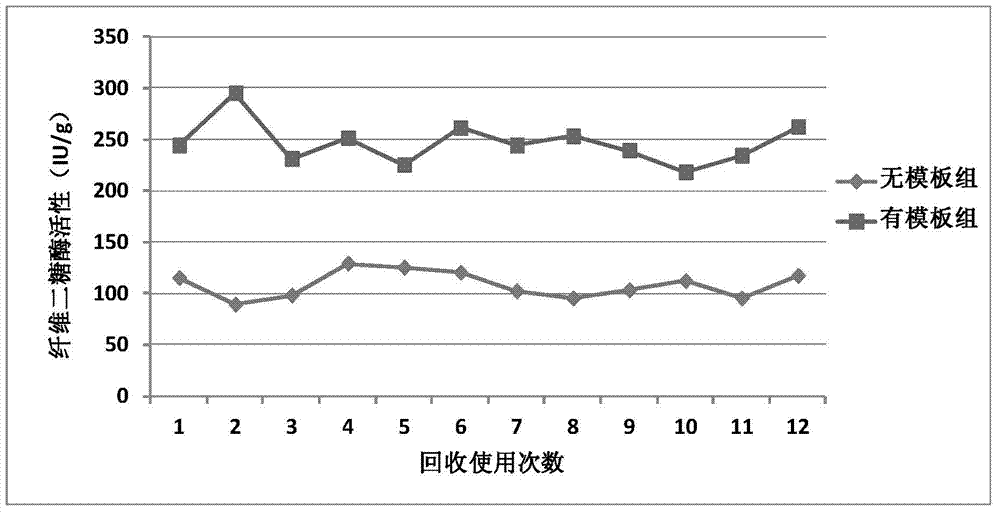

[0062] Embodiment 3: Immobilized enzyme stability and catalytic efficiency are improved

[0063] After using the prepared mesoporous material to immobilize cellulase, the thermal stability is good, and 50% fructose is the template with the highest thermal stability, which is obviously better than immobilized enzyme and free enzyme without template, cellobiose in free cellulase The enzyme activity is around 256IU (37°C), as shown in Table 4 and Table 5:

[0064] Table 4 immobilized cellulase has good thermal stability

[0065]

[0066] Note: (1) Cellulase is a compound enzyme composed of C1 enzyme, Cx enzyme and β-glucosidase (ie cellobiase).

[0067] (2) The enzyme activity curves in Table 4 take the enzyme activity of each enzyme at 37°C as 1. At 37°C, the measured enzyme activity: 0% fructose template mesoporous immobilized cellobiose in cellulase The enzyme activity is 105±8IU, the cellobiase activity in 50% fructose template nano-cellulase is 256±13IU, and the disacch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com