Manganese sesquioxide micro powder and preparation method and application thereof

A technology of manganese trioxide micropowder and divalent manganese salt, which is applied in the direction of manganese oxide/manganese hydroxide, electrical components, battery electrodes, etc., and can solve the problems of negative impact on the safety performance of lithium-ion battery products, waste of raw materials, high impurity content, etc. , to achieve the effect of uniform and controllable product particle size, full utilization of resources, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

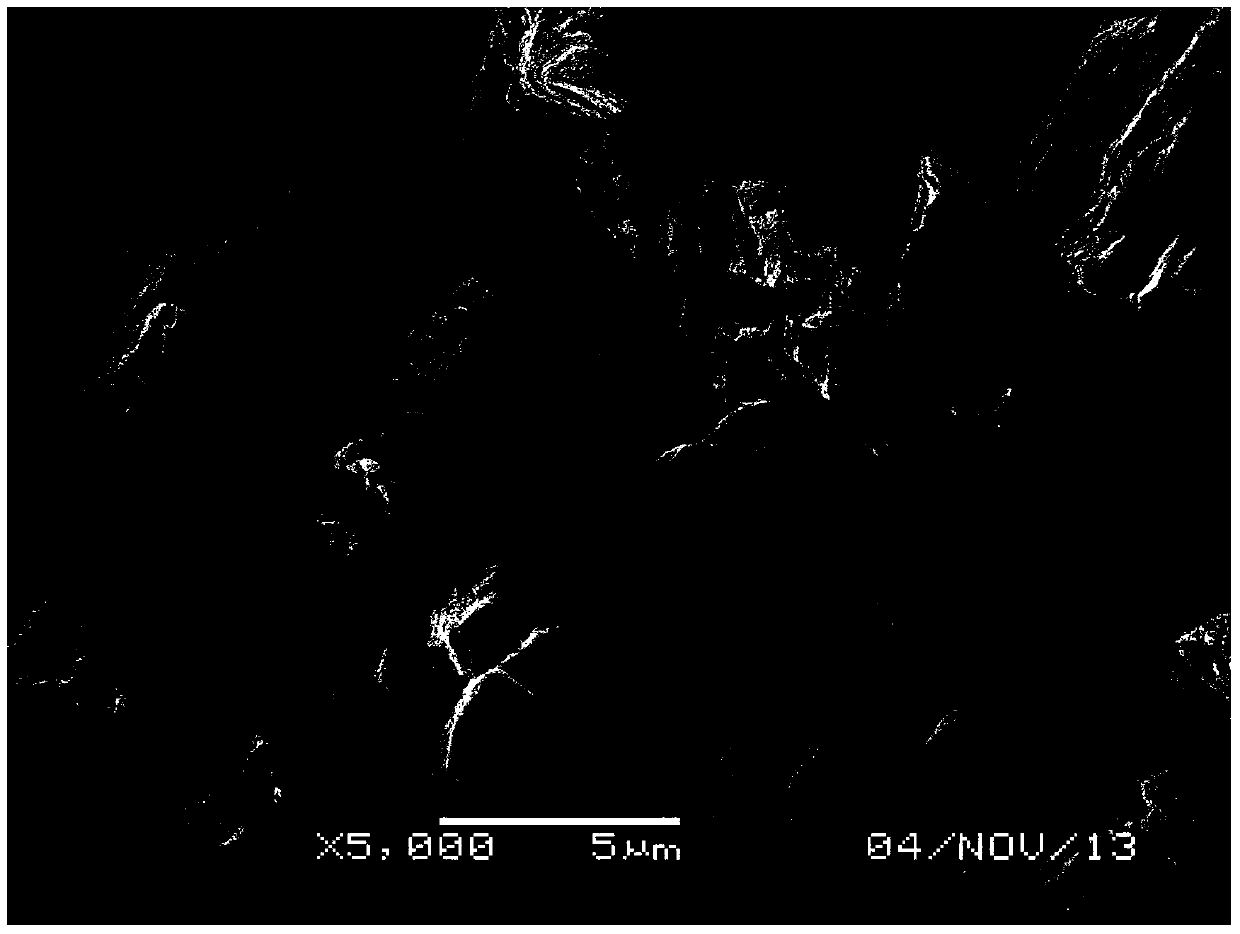

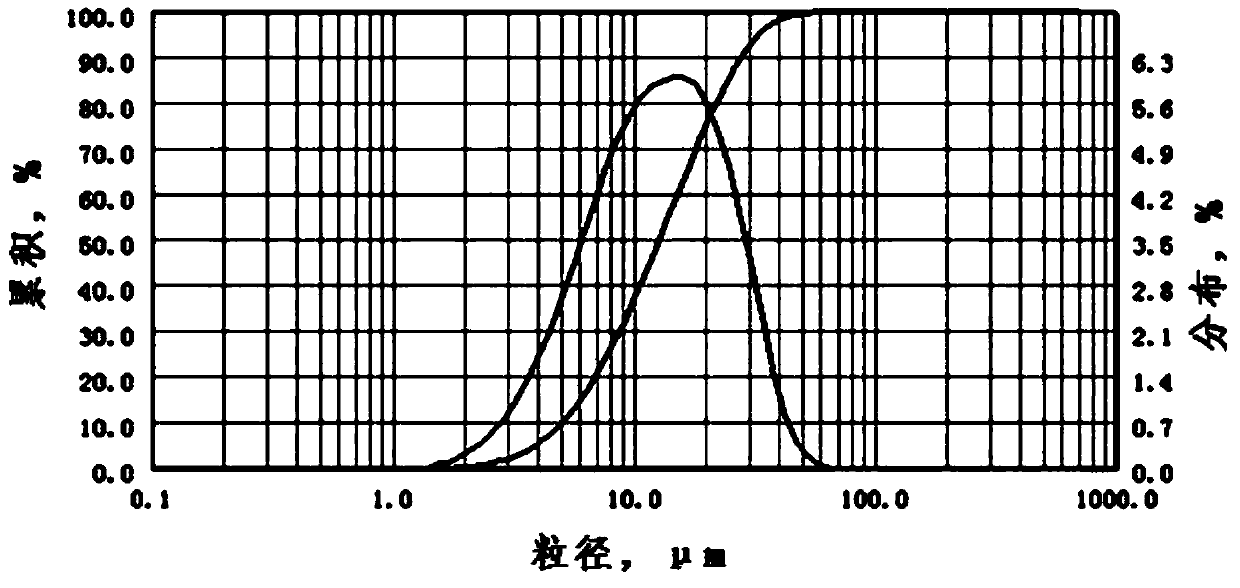

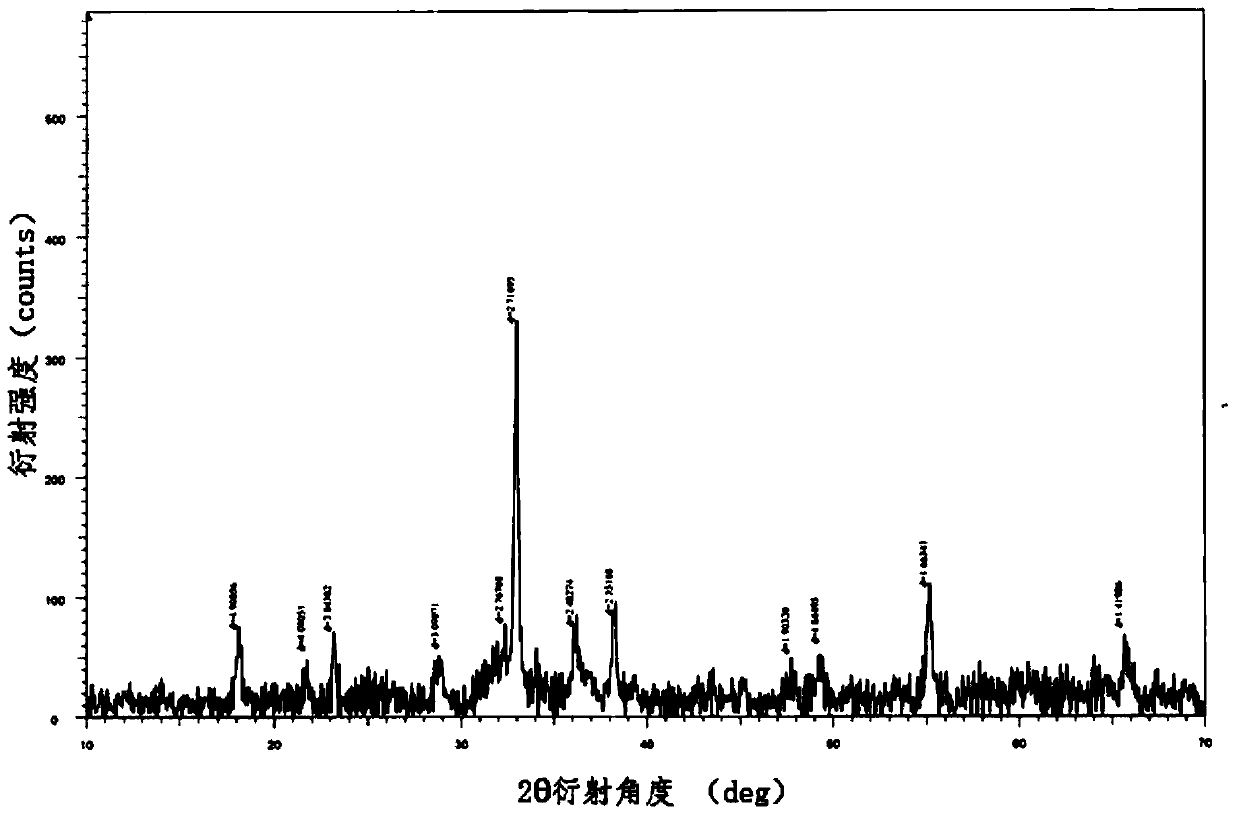

[0044] A kind of manganese trioxide micropowder of the present invention, the particle size index D50 of manganese trioxide micropowder is 9.2 μm, bulk density is 0.6g / mL, tap density is 1.2g / mL, Mn content is 69.2%, Ca element The content is 52ppm, the Mg element content is 48ppm, and the sulfate content is 236ppm.

[0045] The preparation method of above-mentioned manganese trioxide micropowder in the present embodiment specifically comprises the following steps:

[0046] (1) Prepare 1L of manganese sulfate solution with a metal manganese content of 145g / L, prepare 1L of oxalic acid solution with a concentration of 332g / L; prepare ammonia water with a mass fraction of 15%;

[0047] (2) Add 1L of pure water into an 8L reactor as the reaction bottom liquid, stir and heat up to 60°C, and at a temperature of 60°C and under stirring conditions, add the above-mentioned preparation at the same time continuously and at a uniform speed according to the stoichiometric ratio of 1:1. M...

Embodiment 2

[0052] A kind of manganese trioxide micropowder of the present invention, the particle size index D50 of manganese trioxide micropowder is 20.3 μm, bulk density is 0.8g / mL, tap density is 1.3g / mL, Mn content is 68.9%, Ca element The content is 39ppm, the Mg element content is 43ppm, and the sulfate content is 218ppm.

[0053] The preparation method of above-mentioned manganese trioxide micropowder in the present embodiment specifically comprises the following steps:

[0054] (1) Prepare 1L of manganese sulfate solution with a metal manganese content of 55g / L, prepare 1L of oxalic acid solution with a concentration of 126g / L; prepare 200g / L ammonium bicarbonate solution;

[0055] (2) Add 1L of pure water into the 8L reactor as the reaction bottom liquid, stir and heat up to 40°C, at the temperature of 40°C and under stirring conditions, add the above-mentioned preparation at the same time continuously and at a uniform speed according to the stoichiometric ratio of 1:1 Manganes...

Embodiment 3

[0060] A kind of manganese trioxide micropowder of the present invention, the particle size index D50 of manganese trioxide micropowder is 13.2 μm, bulk density is 1.0g / mL, tap density is 1.4g / mL, Mn content is 69.4%, Ca element The content is 47ppm, the Mg element content is 42ppm, and the sulfate content is 208ppm.

[0061] The preparation method of above-mentioned manganese trioxide micropowder in the present embodiment specifically comprises the following steps:

[0062] (1) Prepare a manganese sulfate solution with a metal manganese content of 110g / L, prepare an oxalic acid solution with a concentration of 250g / L (preheated to 60°C); prepare a 240g / L ammonium bicarbonate solution;

[0063] (2) Add about 30L of pure water into a 200L reactor as the reaction bottom liquid, stir and heat up to 60°C, at a temperature of 60°C and under stirring conditions, add the above preparation at the same time continuously and at a uniform speed according to the stoichiometric ratio of 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com