Electron transfer polymer, and preparation method and application thereof

An electron transport, polymer technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of poor carrier mobility, low luminous efficiency of materials, poor luminous efficiency, etc., and improve electron mobility. , the synthesis method is simple, and the manufacturing cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

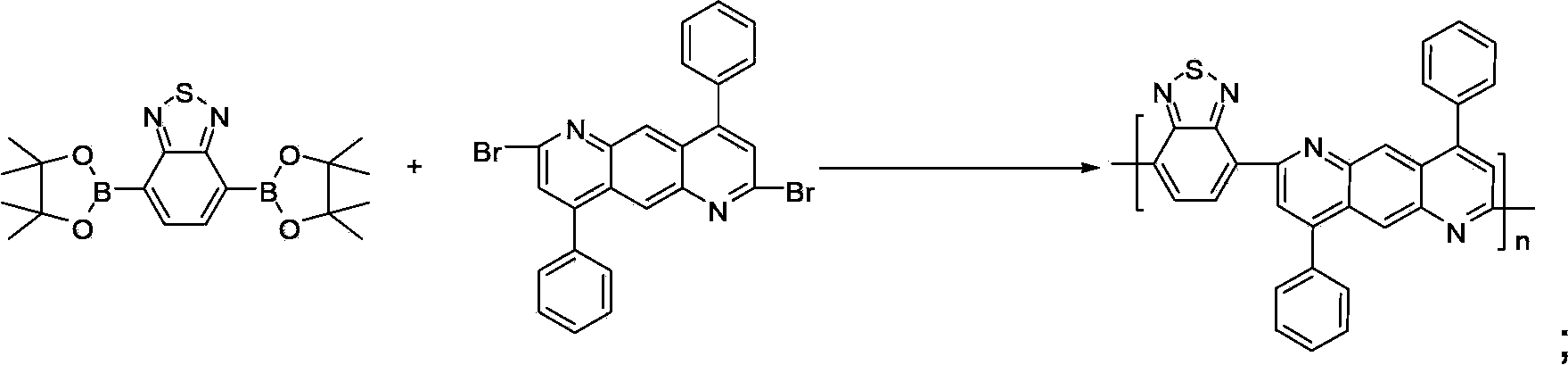

[0026] The preparation method of above-mentioned electron transport polymer, comprises the steps:

[0027] S1, respectively providing compounds A and B represented by the following structural formula,

[0028] That is, 4,7-diboronic acid pinacol ester benzothiadiazole, the compound A is purchased;

[0029] That is, 2,7-dibromo-4,9-diphenylanthrazole, the compound B is synthesized by referring to the method disclosed in the reference document (J.AM.CHEM.SOC.9VOL.125, NO.44, 2003), in This will not be repeated;

[0030] S2. In an oxygen-free environment (nitrogen, argon or a mixture of nitrogen and argon), add compounds A and B into an organic solvent containing a catalyst and an alkali solution, and perform a Suzuki coupling reaction at 70-130°C After 12 to 48 hours, stop the reaction and cool to room temperature, separate and purify to obtain the structural formula: Electron-transporting polymer, wherein, n is an integer of 10 to 100; wherein, the molar ratio of compou...

Embodiment 1

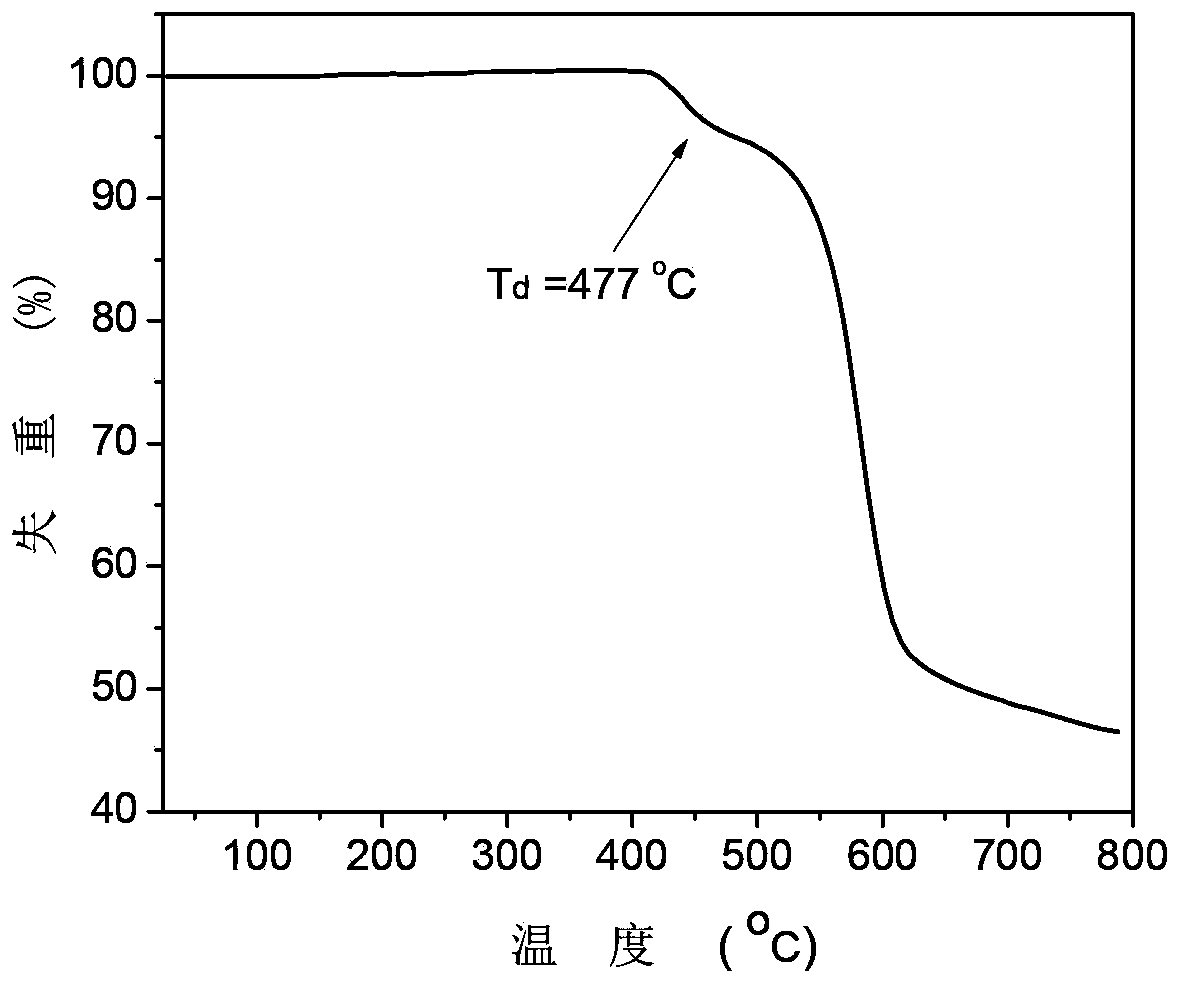

[0042] The electron-transporting polymer of this example, that is, poly{4,7-diylbenzothiadiazole-co-2,7-diyl-4,9-diphenylanthrazole} (n=56), The preparation steps are as follows:

[0043]

[0044] Under argon protection, 4,7-diboronic acid pinacol ester benzothiadiazole (78mg, 0.2mmol), 2,7-dibromo-4,9-diphenylanthrazole (98mg, 0.2mmol ) into a flask filled with 10ml of toluene solvent, and after fully dissolving, potassium carbonate (2mL, 2mol / L) solution was added into the flask, vacuumed to deoxygenate and filled with argon, and then added bistriphenylphosphine dichloride Palladium (5.6mg, 0.008mmol); the flask was heated to 100°C for Suzuki coupling reaction for 48h. Subsequently, the polymerization reaction was stopped after cooling down, and 50 ml of methanol was added dropwise to the flask for sedimentation; after filtering through a Soxhlet extractor, the mixture was sequentially extracted with methanol and n-hexane for 24 hours. Then use chloroform as a solvent t...

Embodiment 2

[0047] The electron-transporting polymer of this example, namely poly{4,7-diylbenzothiadiazole-co-2,7-diyl-4,9-diphenylanthrazole} (n=100), The preparation steps are as follows:

[0048]

[0049] Under the protection of mixed gas of nitrogen and argon, 4,7-diboronic acid pinacol ester benzothiadiazole (116mg, 0.3mmol), 2,7-dibromo-4,9-diphenylanthrazole (147mg , 0.3mmol) and 15mL tetrahydrofuran were added to a two-necked bottle of 50mL size, fully dissolved, and then a mixture of nitrogen and argon was introduced to exhaust the air for about 20 minutes, and then tetrakistriphenylphosphine palladium (4mg, 0.003mmol) was added therein, After fully dissolved, add sodium bicarbonate (3mL, 2mol / L) solution. Then, the mixed gas of nitrogen and argon was exhausted for about 10 minutes, and the two-neck flask was added to 70°C for Suzuki coupling reaction for 96 hours. Subsequently, the polymerization reaction was stopped after cooling down, and 40 mL of methanol was added to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com