High-yield lactic acid bacterium and method for preparing calcium lactate by fermenting eggshells with same

A technology of lactic acid bacteria and calcium lactate, applied in the field of microorganisms, can solve the problems of increasing economic benefits, high energy consumption of the calcination method, environmental pollution, etc., and achieve the effects of overcoming environmental pollution, high purity, and high utilization rate of eggshells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

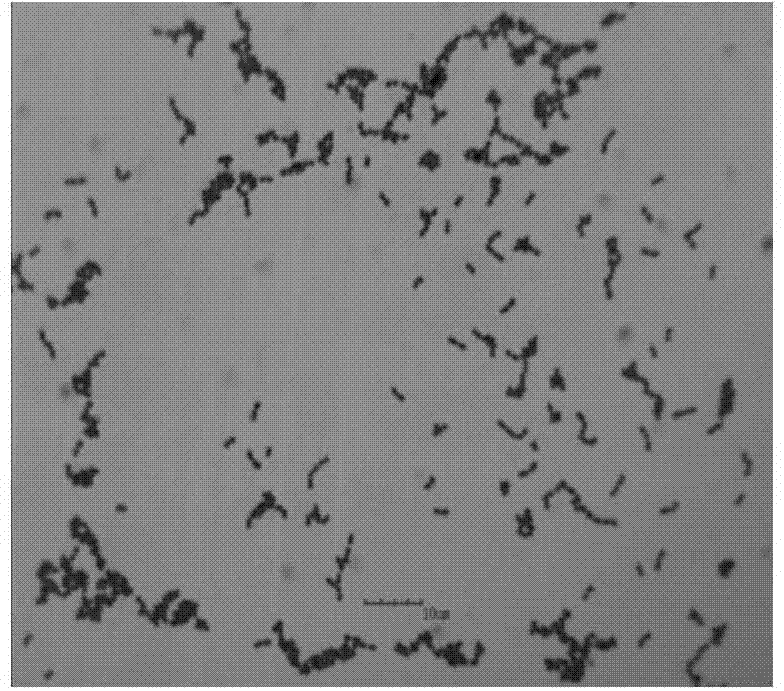

[0036] The isolation of embodiment 1 bacterial strain

[0037] The separation medium is MRS medium, purchased from Qingdao Haibo Biotechnology Co., Ltd., and the ingredients include: peptone 10.0g, beef powder 8.0g, yeast powder 4.0g, glucose 20.0g, sodium acetate 5.0g, dipotassium hydrogen phosphate 2.0g, diammonium hydrogen citrate 2.0g, Tween 801.0g, magnesium sulfate 0.2g, manganese sulfate 0.04g, agar 14g, distilled water 1000mL, pH value 6.5±0.2 (25℃). When using, weigh 66.2g of this product, dissolve it in 1000mL of distilled water by heating, autoclave at 121℃ for 15min, and set aside.

[0038] Lactic acid bacteria re-screening verification medium MC medium, purchased from Qingdao Haibo Biotechnology Company, contains: soybean peptone 5.0g, beef extract powder 3.0g, yeast extract powder 3.0g, glucose 20.0g, lactose 20.0g, calcium carbonate 10.0 g, agar 15.0g, neutral red 0.05g, distilled water 1000mL, pH 6.0 (25°C). When using, weigh 80.0g of this product, heat to bo...

Embodiment 2

[0045] Mutation and identification of embodiment 2 bacterial strains

[0046] 2.1 Study the effects of ultraviolet mutagenesis and nitrosoguanidine mutagenesis on the ability of lactic acid production:

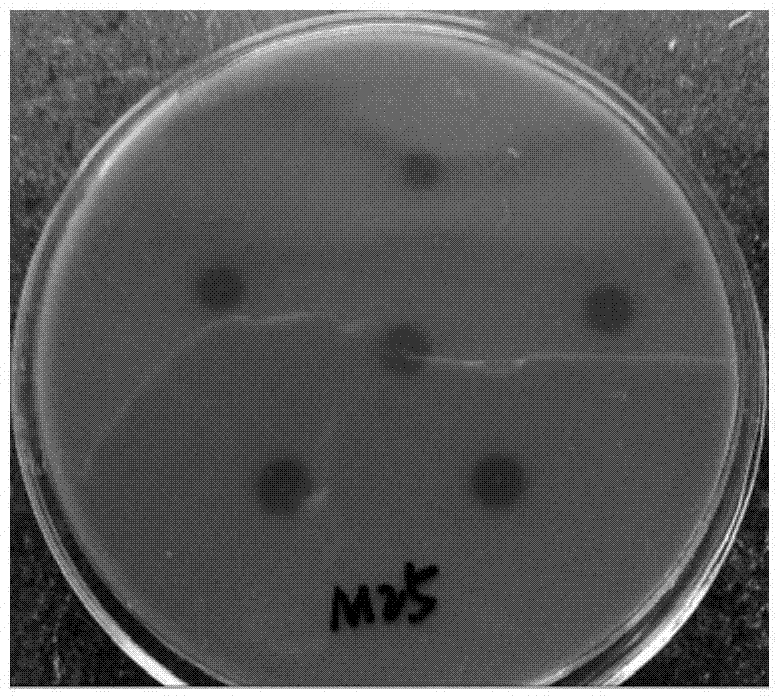

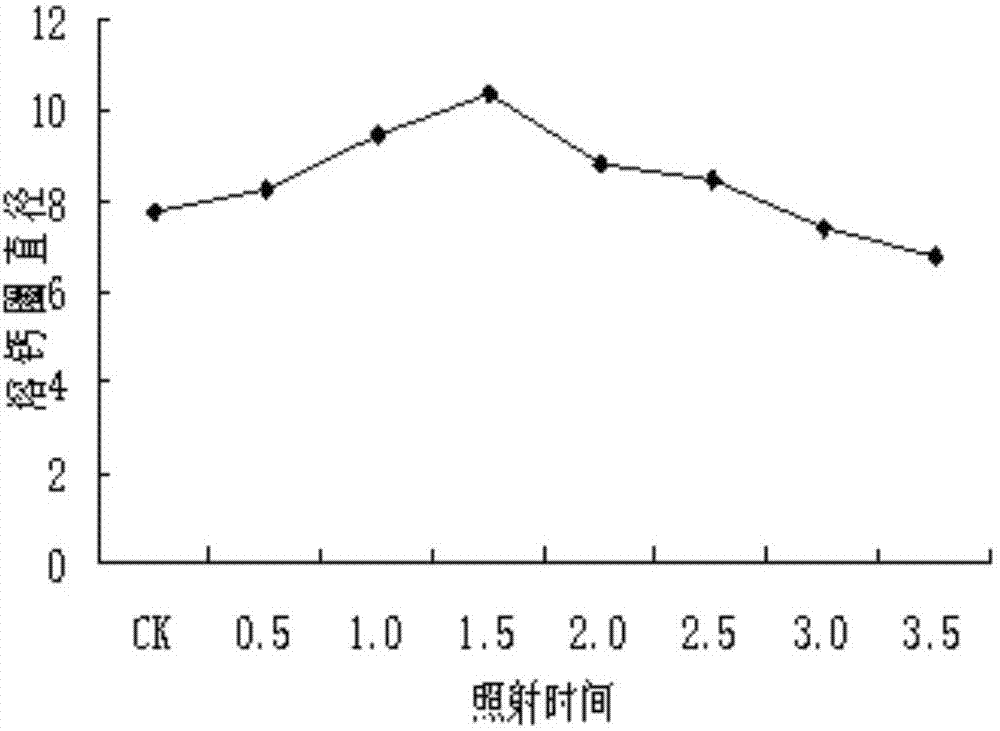

[0047] 2.1.1 Ultraviolet (UV) mutagenesis

[0048] Take the slant of the bacteria, add 10mL of sterile water to make a suspension, take 0.1mL and spread it on 8 plates, culture it anaerobically at 37°C for 24h, and then place it under a 20W ultraviolet lamp for mutagenesis, and the irradiation distance is 30cm. Irradiate for 0.5min, 1.0min, 1.5min, 2.0min, 2.5min, 3min, 3.5min respectively, take the plate without UV irradiation as the control (CK), and then culture anaerobically at 37℃ for 24h. Spot the culture on the MC solid plate, culture anaerobically at 37°C for 42 hours, measure the diameter of the calcium-dissolving circle with a vernier caliper, measure 3 calcium-dissolving circles, take the average value, and compare the size of the calcium-dissolving circle at diffe...

Embodiment 3

[0094] The research of embodiment 3 strains producing lactic acid ability and fermentation time

[0095] 1. Acid production capacity of the strain

[0096] The components of the fermentation medium are configured as follows: peptone 0.5g, tryptone 0.5g, yeast extract 1.0g, glucose 10g, CaCl 2 0.008%, MgSO 4 0.192%, K 2 HPO 4 0.04%, KH 2 PO 4 0.04%, NaHCO 3 0.4%, NaCl0.08%, distilled water 100mL. Sterilize at 115°C for 20 minutes. Neutralizer calcium carbonate 6g, sterilized separately. Insert the logarithmic phase seed solution of lactic acid bacteria isolated in the present invention with an inoculation amount of 2%, and take Lactobacillus bulgaricus, which is the most commonly used strain for industrial fermentation to produce lactic acid at present, as a control. Incubate at 35°C for 72 hours on a 180r / min shaker. Place it at 85°C for 30 minutes, kill the bacteria, and filter. Take 1.0mL of the filtered fermentation broth, add 50mL of distilled water, then add 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com