Preparation method of doped nano-titanium dioxide with visible-light activity and preparation method of polishing emulsion of visible light photocatalytic photocatalyst

A nano-titanium dioxide, visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, polishing compositions, etc., can solve the problems of reducing photon quantum efficiency, low solar energy utilization rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

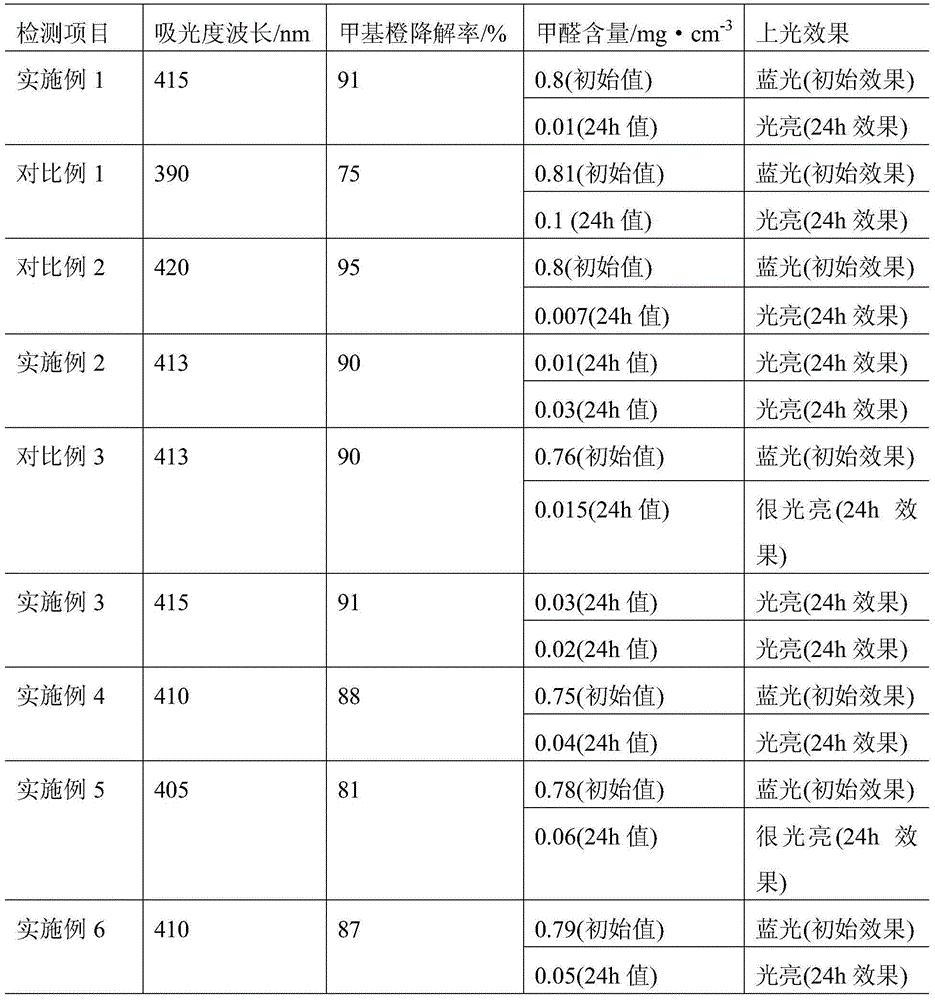

Examples

Embodiment 1

[0033] (1) Silver and nitrogen co-doped anatase titanium dioxide

[0034] Weigh 0.05 mol of tetrabutyl titanate and dissolve it in 15 mL of absolute ethanol, mix and stir for 15 minutes, add 0.01 mol of malic acid and mix well to obtain solution A;

[0035] Weigh 0.05mol silver nitrate, 0.025mol urea dissolved in 15mL absolute ethanol and 1mL deionized water, then add 0.025mol sodium thiosulfate, and use 1mol / L nitric acid to adjust the pH=3, mix well to obtain B solution ;

[0036] Slowly add B solution to A solution, aging, when the solution turns from sol to gel, put it in a vacuum drying oven at 80°C for drying, grinding, and continue calcination in a muffle furnace at 400°C 2h, grinding, you can get silver and nitrogen co-doped TiO 2 ;

[0037] (2) Preparation of the aqueous phase of the photoemulsion on the photocatalyst active photocatalyst dissolved in visible light

[0038] Weigh 0.01g of carboxylate and directly stir and disperse it in 100g of aqueous solution, and then add ...

Embodiment 2

[0045] (1) Silver and nitrogen co-doped anatase titanium dioxide

[0046] Weigh 0.05 mol of tetrabutyl titanate and dissolve it in 15 mL of absolute ethanol, mix and stir for 15 minutes, add 0.025 mol of glacial acetic acid and mix well to obtain A solution;

[0047] Weigh 0.3 mol of silver nitrate and 0.15 mol of ammonium carbonate in 15 mL of absolute ethanol and 1 mL of deionized water, then add 0.05 mol of sodium thiosulfate, and use 1 mol / L of nitric acid to adjust pH=4, mix well, and obtain B Solution

[0048] Slowly add B solution to A solution, aging, when the solution turns from sol to gel, put it in a vacuum drying oven at 60 ℃ for drying, grinding, continue to calcine in a muffle furnace at 300 ℃ 1h, grinding, you can get silver and nitrogen co-doped TiO2;

[0049] (2) Preparation of the aqueous phase of the photoemulsion on the photocatalyst active photocatalyst dissolved in visible light

[0050] Weigh 0.05g of sulfuric acid ester and directly stir and disperse it in 100g...

Embodiment 3

[0056] (1) Silver and nitrogen co-doped anatase titanium dioxide

[0057] Weigh 0.05 mol of tetrabutyl titanate and dissolve it in 15 mL of absolute ethanol, mix and stir for 15 minutes, add 0.015 mol of citric acid and mix well to obtain A solution;

[0058] Weigh 0.15mol silver nitrate, 0.07mol thiourea dissolved in 15mL of absolute ethanol and 1mL of deionized water, then add 0.01mol of sodium thiosulfate, and use 1mol / L of nitric acid to adjust the pH=2, mix well to obtain B Solution

[0059] Slowly add B solution to A solution, aging, and when the solution turns from sol to gel, put it in a vacuum drying oven at 100°C for drying, grinding, and continue calcination in a muffle furnace at 600°C 3h, grinding, you can get silver and nitrogen co-doped TiO 2 ;

[0060] (2) Preparation of the aqueous phase of the photoemulsion on the photocatalyst active photocatalyst dissolved in visible light

[0061] Weigh 0.025g of phosphate and directly stir and disperse it in 100g of aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com