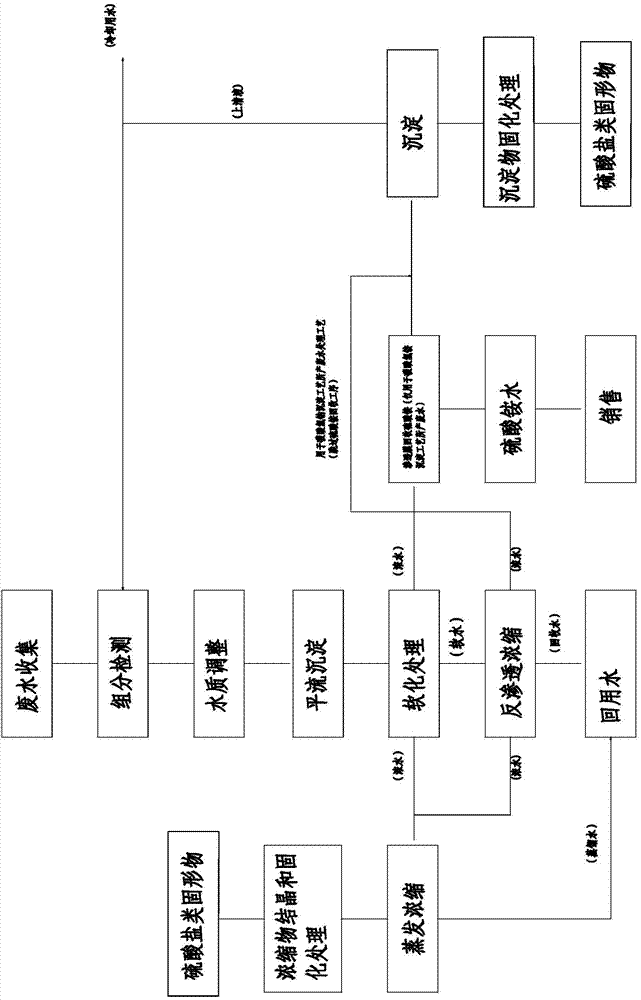

Method for recovering water and sulfate substances from rare earth sulfate production wastewater

A sulfate and production waste water technology, which is applied in the field of recycling water and sulfate substances, can solve the problems of inability to achieve clean production goals, poor treatment effects, and low treatment efficiency, and achieve treatment costs without secondary pollution and treatment costs The effect of low, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

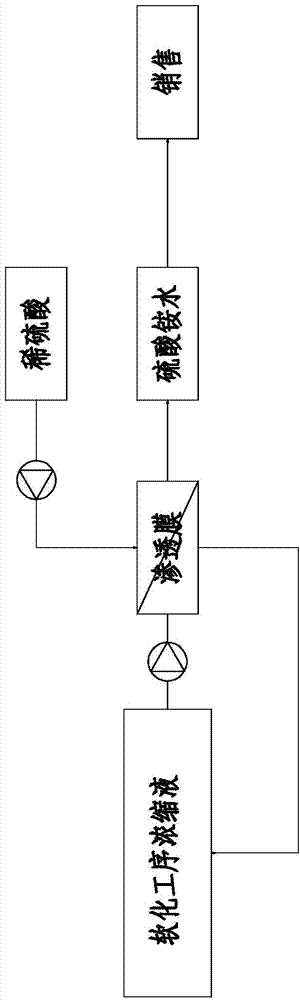

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1; To the sulfuric acid wastewater pilot test (August 2013) of a rare earth enterprise in Baotou, Inner Mongolia, the steps are as follows:

[0049] (1) Component detection: The wastewater is sulfuric acid wastewater produced by the sodium bicarbonate precipitation process. After testing: the amount of wastewater is 0.8 tons, and there are obviously suspended and precipitated calcium and magnesium salts in the wastewater; pH: 6.17; conductivity: 25200us / cm; soluble solids: 3.5%; total hardness: 2129.57 mg / L (CaCO 3 ).

[0050] (2) Pretreatment: According to the water quality index of the wastewater, stir and add sodium hydroxide solution, adjust the pH to 9.5, settle for 2 hours, and filter the supernatant with a 5 μm bag filter to remove large suspended particles in it The next processing procedure. After the sediment is collected, it is separated by a centrifuge, weighed, dried and stored.

[0051] Softening treatment: Add polyepoxysuccinic acid (PESA) ...

Embodiment 2

[0054] Example 2: Commissioning of a sulfuric acid wastewater treatment project carried out by a rare earth enterprise under Inner Mongolia Baotou Iron and Steel Company (February 2014), including the following steps:

[0055] (1) Component detection: The wastewater is sulfuric acid wastewater produced by the sodium bicarbonate precipitation process. The amount of wastewater treated on that day is 30 tons, and there are suspensions and sediments visible to the naked eye in the wastewater. Its pH: 6.50; conductivity: 42000us / cm; soluble solids 5%.

[0056] (2) Pretreatment: According to the water quality index of the wastewater, add sodium hydroxide and sodium carbonate solution respectively under stirring, and adjust the pH to 10.3; advective precipitation, the supernatant adopts a 25 μm bag filter and a 0.1um microfiltration membrane Combined filtration, the filtrate is transferred to the next treatment process; the sediment is filtered out with a plate and frame filter press...

Embodiment 3

[0060]Embodiment three: the pilot test (in March 2014) of the ammonium bicarbonate process wastewater of a rare earth enterprise in Baotou, Inner Mongolia, including the following steps:

[0061] (1) Component detection: The wastewater is the wastewater produced by the ammonium bicarbonate precipitation process. After testing, the amount of wastewater is 0.95t. There are obviously suspended and precipitated calcium and magnesium salts in the wastewater, and it emits a heavy ammonia smell. Its pH: 8.9; conductivity: 32000us / cm; soluble solids: 4.5%.

[0062] (2) Pretreatment: According to the water quality index of the wastewater, stir and add sodium hydroxide solution, adjust the pH to 9.7, and settle for one hour. The supernatant is filtered with a 1 μm filter element and then transferred to the next treatment process. After the sediment is collected, it is separated by a centrifuge and dried for storage.

[0063] Softening treatment: add aspartic acid or maleic anhydride to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com