Method for preparing injection-grade alpha-cyclodextrin

A cyclodextrin, injection-grade technology, applied in the field of biochemistry, can solve the problems of organic solvent residue, low product quality, strong reaction, etc., and achieve the effect of low production cost, high reactivity, and promotion of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

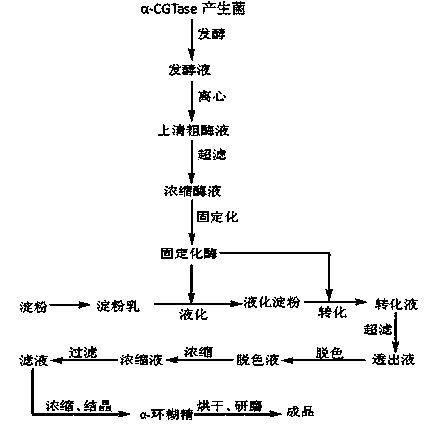

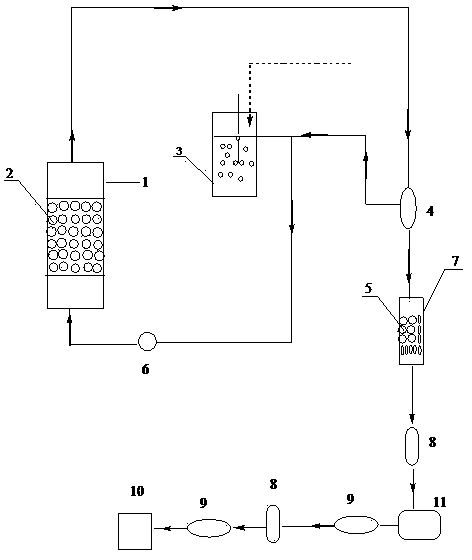

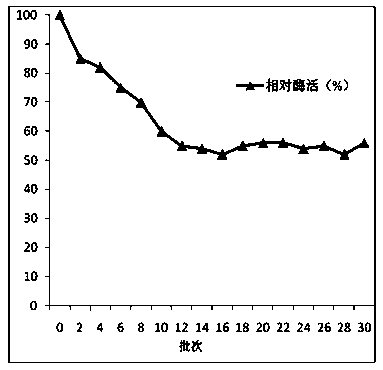

Method used

Image

Examples

Embodiment 1

[0038] step 1:

[0039] Genetically engineered bacteria E.coli BL21(DE3) / pet24a(+) (China Center for Type Microorganisms Collection, CCTCCM208063) inoculated in LB medium, cultured at 30-37°C for 6-12 hours, then transferred to TB medium, cultured at 30-37°C for 2-6 hours, added 0.01% IPTG and cooled Cultivate at 20-28°C for 30-36 hours to obtain a fermentation broth. The fermented liquid was taken and centrifuged at 6000rpm for 20min in a high-speed refrigerated centrifuge to obtain a supernatant. The supernatant was taken to measure the enzyme activity according to the method of A Spectrophotometric Assay for the Cyclization Activity of Cyclomaltohexaose (α-Cyclodextrin) Glucanotransferase in the literature, and the cyclization activity was 50 U / ml.

[0040] Take the supernatant, adjust the pre-membrane pressure of the ultrafiltration membrane unit to 1MPa, and the post-membrane pressure to 0.4MPa, and then enter the ultrafiltration membrane filtration system (the cut-o...

Embodiment 2

[0057] step 1:

[0058] Bacillus softening ( Bacillus macerans ) inoculated in LB medium, cultured at 30-37°C for 6-12 hours, then transferred to fermentation medium (g / L): corn steep liquor 60, corn flour 20, dipotassium hydrogen phosphate 1.5, magnesium sulfate 0.2, sodium carbonate 10, pH 7.0, cultured at 35°C for 30-36 hours to obtain a fermentation broth. The fermented liquid was taken and centrifuged at 6000rpm for 20min in a high-speed refrigerated centrifuge to obtain a supernatant. The supernatant was taken to measure the enzyme activity according to the method in Example 1, and the cyclization activity was 30 U / ml.

[0059] Take the supernatant, adjust the pre-membrane pressure of the ultrafiltration membrane unit to 1MPa, and the post-membrane pressure to 0.4MPa, then enter the ultrafiltration membrane filtration system (the cut-off pore size of the ultrafiltration membrane is 10000), the working temperature is 30 ° C ~ 40 ° C, water and Some small molecular su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com