Tea extract-containing microemulsion, preparation method and applications thereof

A technology of tea extract and microemulsion, which is applied in application, food preparation, food science, etc., can solve the problems of being easily affected by light, heat, oxygen and pH, low bioavailability, poor stability, etc., and achieve enhanced bioavailability , Expand the scope of application, the effect of strong anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Prescription composition

[0053]

[0054]

[0055] 2. Preparation method

[0056] (1) Accurately weigh the prescription amount of EGCG, mix and dissolve it with water, add ascorbic acid and citric acid to adjust the pH of the solution to 4.2;

[0057] (2) Weigh the prescription amount of soybean phospholipid and absolute ethanol as the compound emulsifier, stir to dissolve;

[0058] (3) Add the EGCG aqueous solution of step (1) to the composite emulsifier at a speed of 10 mL / min, stir at 60°C for 45 minutes, and stir at 100 rpm to obtain an emulsified mixture;

[0059] (4) Mix ethyl oleate, caprylic acid, and glyceryl capsaicin evenly according to the prescription ratio to obtain the oil phase;

[0060] (5) Add the emulsified mixture to the oil phase of the formula, and continue to stir at 40°C and 500 rpm until a homogeneous and transparent solution is obtained.

[0061] For the water-oil-surfactant dispersion system, if it is a homogeneous system with transparent or nearly tr...

Embodiment 2

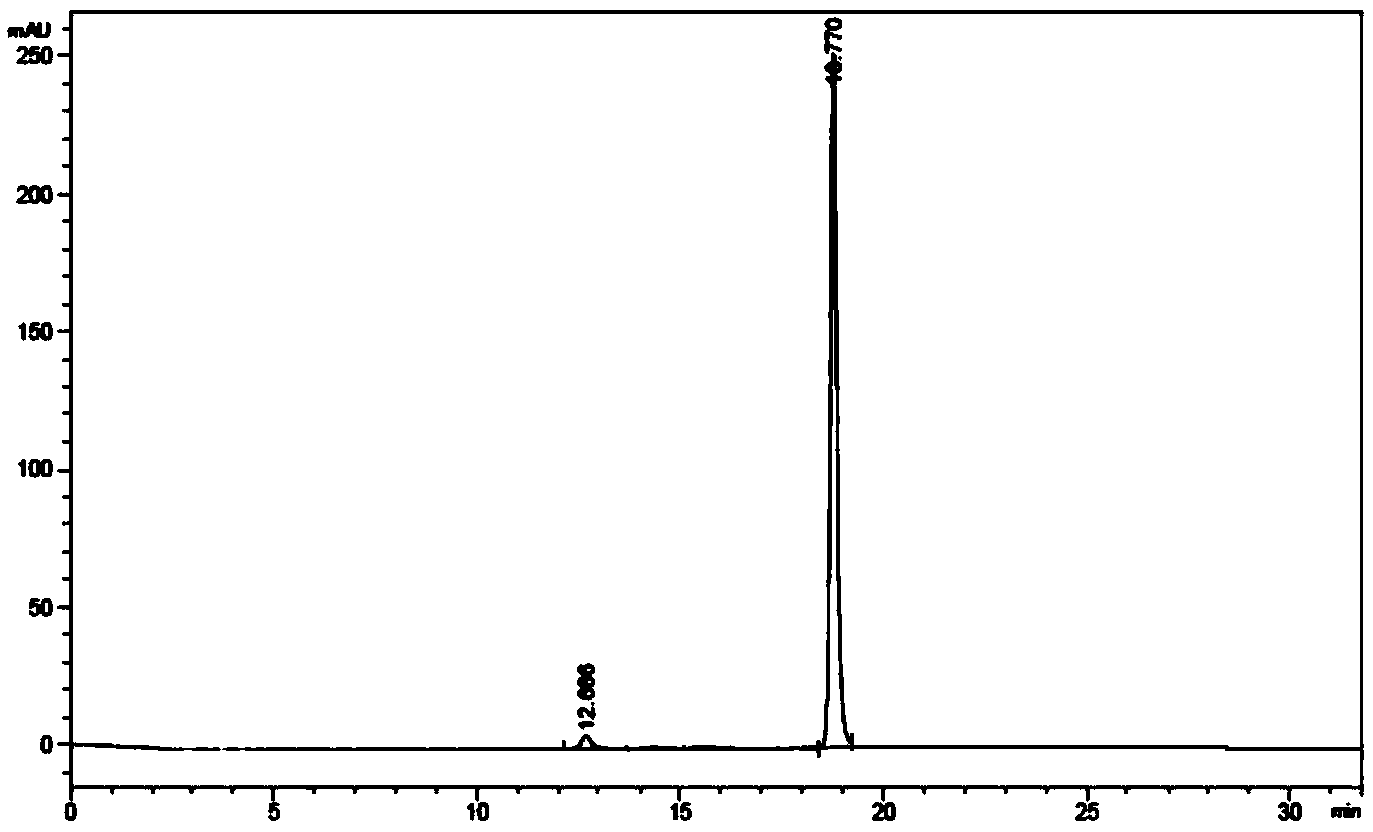

[0070] 1. The effect of synergist on the stability of EGCG in microemulsion

[0071] Prepare microemulsions containing different synergists (citric acid, ascorbic acid) to investigate the effects of ascorbic acid and citric acid on the stability of EGCG in the EGCG microemulsion system. See Table 2 for the microemulsion formula, and refer to Example 1 for the preparation method.

[0072] Air was constantly introduced into each microemulsion, and the oxidation of EGCG was accelerated at 120°C. The content of EGCG in different microemulsions was measured every 2 hours, and the effects of the addition of ascorbic acid and citric acid on the stability of EGCG content in microemulsions were compared. .

[0073] Table 2

[0074]

[0075] The result is Image 6 (The ordinate represents the content of EGCG in the microemulsion as a percentage of the content of EGCG before the treatment). As time goes by, the content of EGCG in the microemulsion is gradually oxidized and its content is gradual...

Embodiment 3

[0084] 1. Prescription composition

[0085]

[0086] Oleic acid polyethylene glycol glyceride (LABRAFIL M1944CS) 13%

[0087] Caprylic, glyceryl capsaicin 30.9%

[0088] Water1%.

[0089] 2. Preparation method

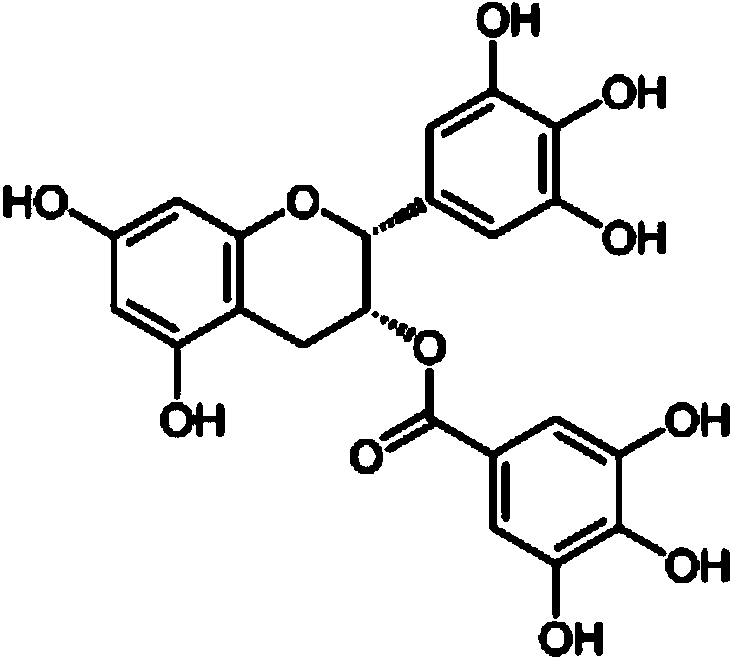

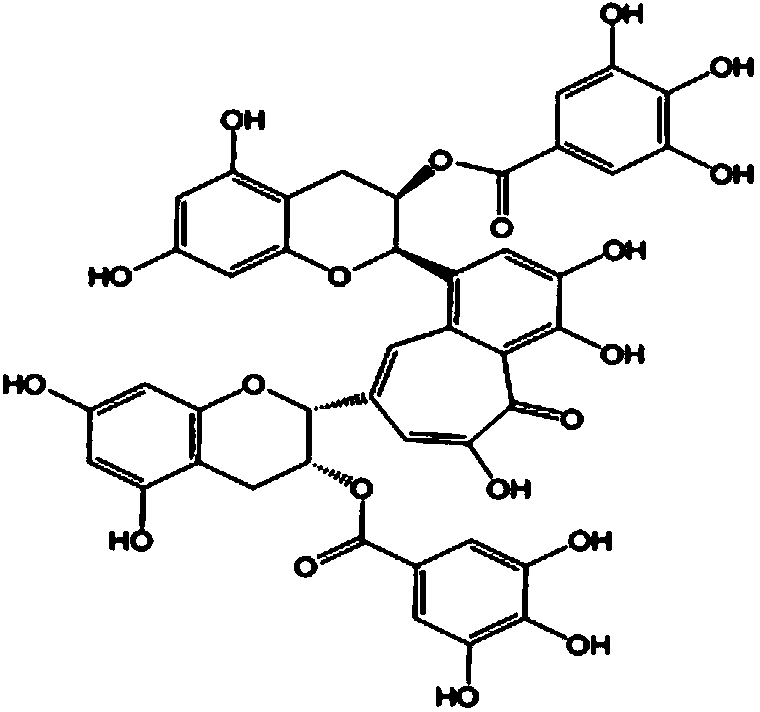

[0090] (1) Accurately weigh the prescription amount of TFDG, mix and dissolve with water, add ascorbic acid and citric acid to adjust the pH of the solution to 5.5;

[0091] (2) Weigh the prescription amount of soybean phospholipid and absolute ethanol as the compound emulsifier, stir to dissolve;

[0092] (3) Add the TFDG aqueous solution of step (1) to the composite emulsifier at a speed of 90 mL / min, stir at 40°C for 120 min, and stir at 300 rpm to obtain an emulsified mixture;

[0093] (4) Mix oleic acid polyethylene glycol glyceride (LABRAFIL M1944CS) with caprylic acid and capric acid glyceride according to the prescription ratio to obtain the oil phase;

[0094] (5) Add the emulsified mixture to the oil phase of the formula, and continue to stir at 60°C and 1000 rpm until a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com