A kind of water-soluble compound fertilizer synergist and preparation method thereof

A compound fertilizer and synergist technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of easy volatilization of N element, easy leakage of K element, easy fixation of P element, etc., to increase fertilizer efficiency and improve fertilizer utilization The effect of large rate and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

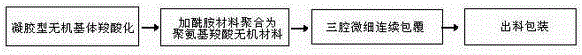

Method used

Image

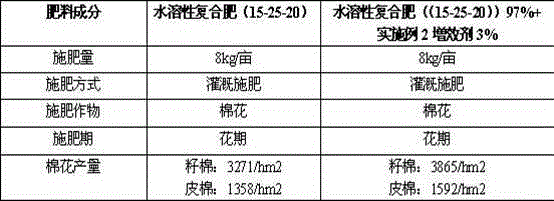

Examples

Embodiment 1

[0037] (1) 50 parts by weight of silica gel was stirred by microwave oscillation to make a suspension with a concentration of 10wt%, and then added sodium tripolyphosphate with a mass of 0.2% of silica gel to disperse for 20-30 minutes;

[0038] (2) Under the condition of 65°C, the silica gel suspension obtained in step 1) was stirred and acidified with 25 parts by weight of acetic acid for 1 hour, and then aged for 24 hours;

[0039] (3) Polymerize the acidified compound obtained in step 2) with 5 parts by weight of formamide and 3 parts by weight of catalyst sodium thiosulfate in an enamel reactor. The polymerization conditions in the reactor are: pressure 5MPa, temperature 100°C, paddle The stirring speed is 150rpm, and the stirring reaction time is 30min, so that the acidified silica gel and formamide are polymerized into polyaminocarboxylate silica gel, and then filtered to dry;

[0040] (4) Disperse and coat 1 part by weight of α-cyclodextrin, 0.5 parts by weight of ethy...

Embodiment 2

[0042] (1) Under stirring state, 55 parts by weight of attapulgite was stirred by microwave oscillation to make a suspension with a concentration of 10wt%, and then 0.5% sodium pyrophosphate of attapulgite was added to disperse for 25 minutes;

[0043] (2) Under the condition of 80°C, the suspension obtained in step 1) was stirred and acidified with 30 parts by weight of pimelic acid for 2 hours, and then aged for 48 hours;

[0044] (3) Polymerize the acidified product obtained in step 2) with 10 parts by weight of urea and 5 parts by weight of catalyst sodium bisulfite in an enamel reactor. The polymerization conditions in the reactor are: pressure 7MPa, temperature 85°C, paddle stirring The speed is 200rpm, and the stirring reaction time is 60min, so that the acidified inorganic matrix and urea material are polymerized into polyaminocarboxylic acid inorganic material, and then filtered to dry;

[0045] (4) 2 parts by weight of acrylamide, 1 part by weight of diethylenetriami...

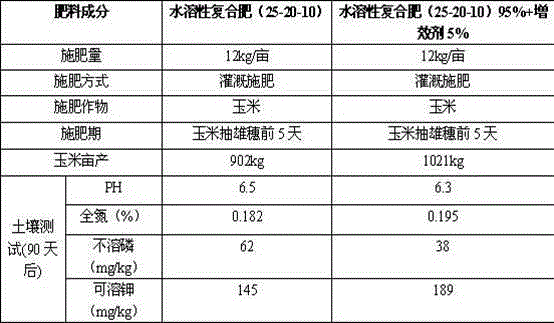

Embodiment 3

[0050] (1) 60 parts by weight of lithium magnesium silicate was stirred by microwave oscillation to make a suspension with a concentration of 10 wt%, and then sodium hexametaphosphate with a mass of 0.3% of lithium magnesium silicate was added to disperse for 20 minutes;

[0051] (2) Under the condition of 70°C, the suspension obtained in step 1) was stirred and acidified with 25 parts by weight of succinic acid for 1.5 hours, and then aged for 24 hours;

[0052] (3) Polymerize the acidified product obtained in step 2) with 15 parts by weight of acetamide and 4 parts by weight of catalyst sodium sulfite in a reactor. The polymerization conditions in the reactor are: pressure 6 MPa, temperature 80-100 ° C, paddle stirring speed 100-200rpm, stirring reaction time 35min, make the acidified inorganic matrix and acetamide material polymerized into polyaminocarboxylate magnesium lithium silicate, and then filter dry;

[0053] (4) Disperse and coat 3 parts by weight of hydroxypropyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com