Method and system for preparing biological oil by antibiotic bacteria residue

A technology of antibiotic bacteria residue and bio-oil, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of increasing operating costs and operating difficulties, and achieves easy separation and further processing, good environmental protection effects, and good energy-saving effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

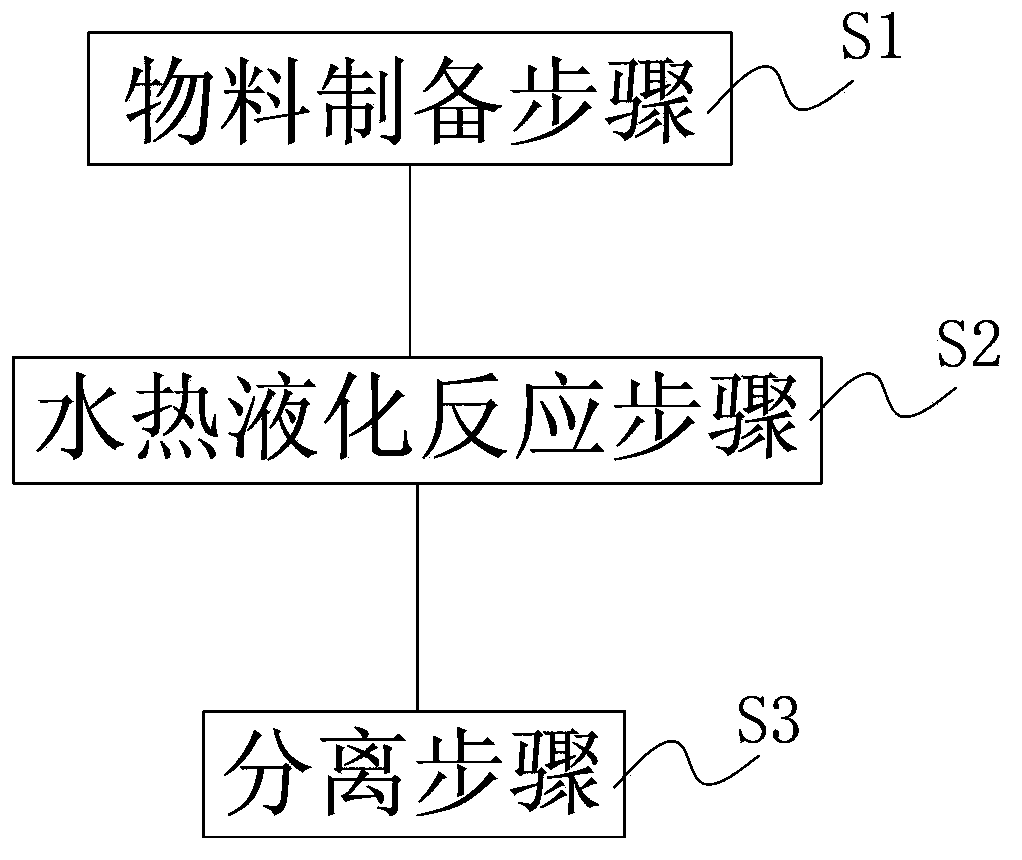

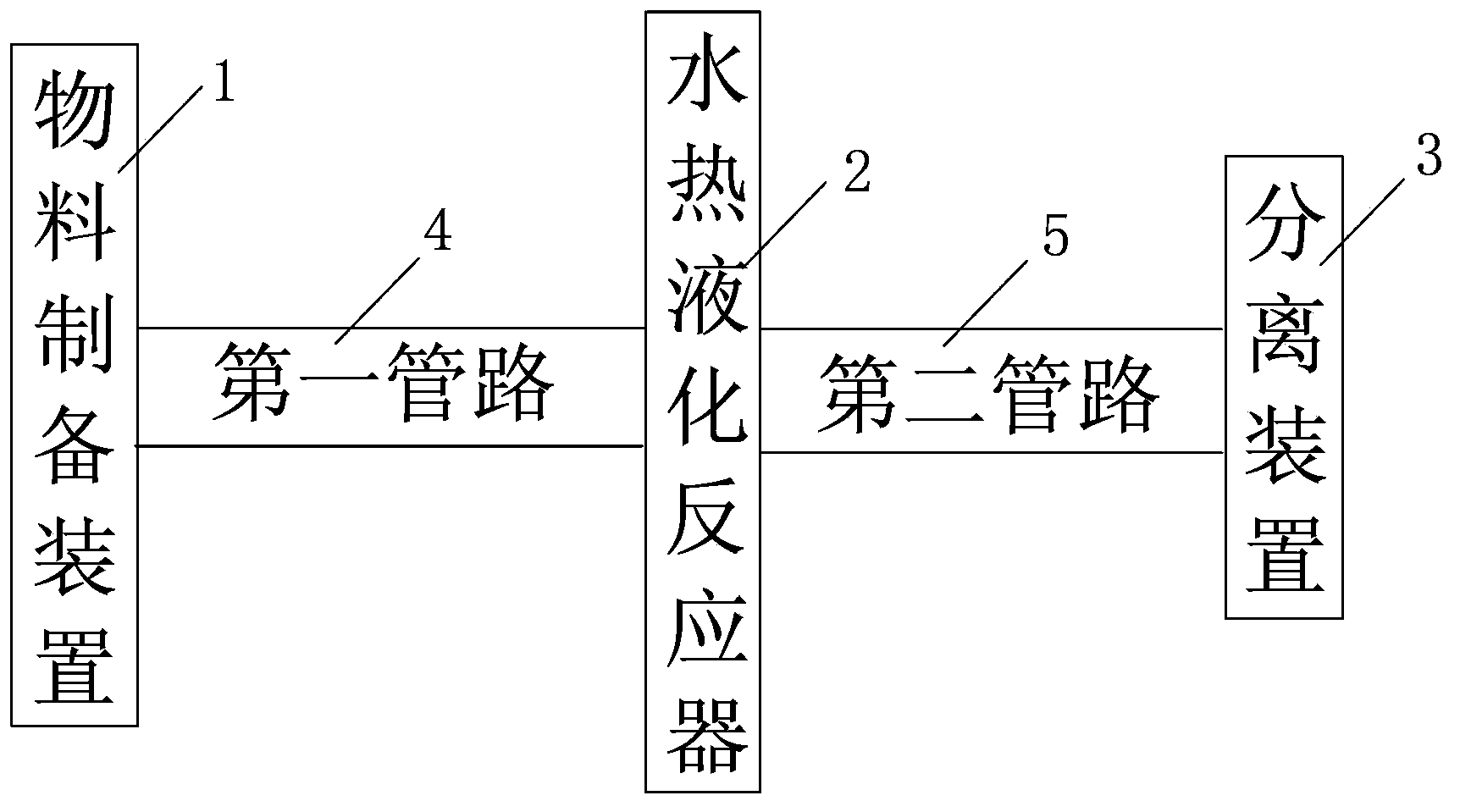

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 (batch type hydrothermal liquefaction)

[0056] 500g of penicillin slag with a water content of 80% and 10g of potassium carbonate were mixed and stirred evenly, then added to a high-pressure stirred reactor with a volume of 5L, and the air in the reactor was replaced with nitrogen after sealing. Heating to 300°C, the pressure is about 9MPa. Keep it in this state for 60 minutes, and cool the material down to room temperature through the cooling coil in the kettle. After the product was separated, 35.5g of bio-oil was obtained, with a yield of 35.5% (calculated on a dry basis of antibiotic residue), and a combustion value of 35MJ / kg. No penicillin residue was detected in the product.

Embodiment 2

[0057] Embodiment 2 (continuous hydrothermal liquefaction)

[0058] Mix the lincomycin residue with a water content of 78% and the sodium carbonate solution with a concentration of 20% in a mass ratio of 10:1, preheat to about 60°C, and then send it into the coiled tube via a plunger pump. The hydrothermal liquefaction reaction is carried out in the reactor. The reaction temperature is 300°C, the pressure is 10-12MPa, and the reaction residence time is 30min. After the reaction product passes through waste heat recovery device and cooling and depressurization equipment, bio-oil is obtained by separation. The yield of bio-oil was 38.0% (calculated on the dry basis of antibiotic residue), and the combustion value was 35MJ / kg. No lincomycin residue was detected in the product.

[0059] The invention can directly treat wet antibiotic residues, realize harmful substance removal and biomass energy conversion at the same time, the product is easy to separate, liquid biofuel can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com