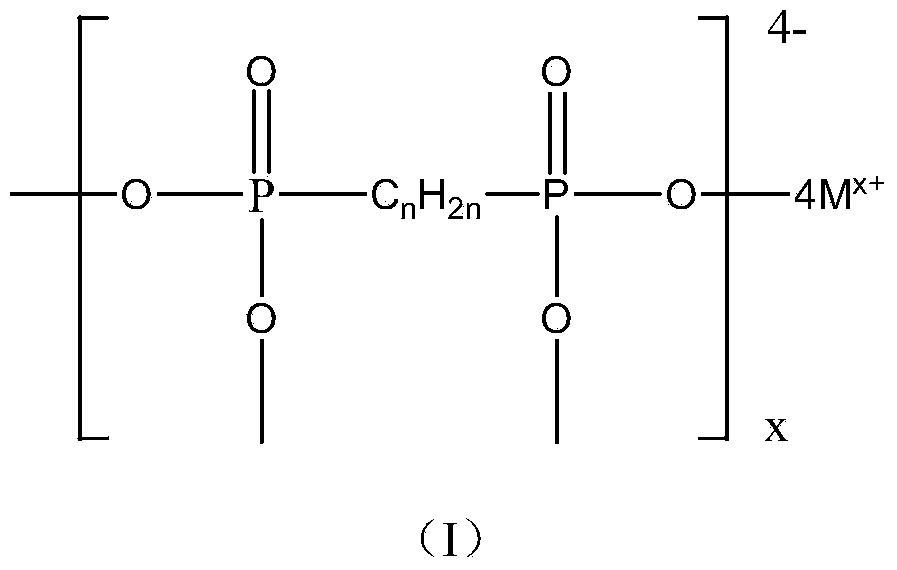

Organic phosphinate flame retardant and preparation method thereof

An organic phosphite and flame retardant technology, applied in the chemical industry, can solve the problems of high equipment and safety requirements, complex processes, high reaction pressure, and achieve good thermal stability of products, cheap and easy-to-obtain raw materials, and high reaction pressure. mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

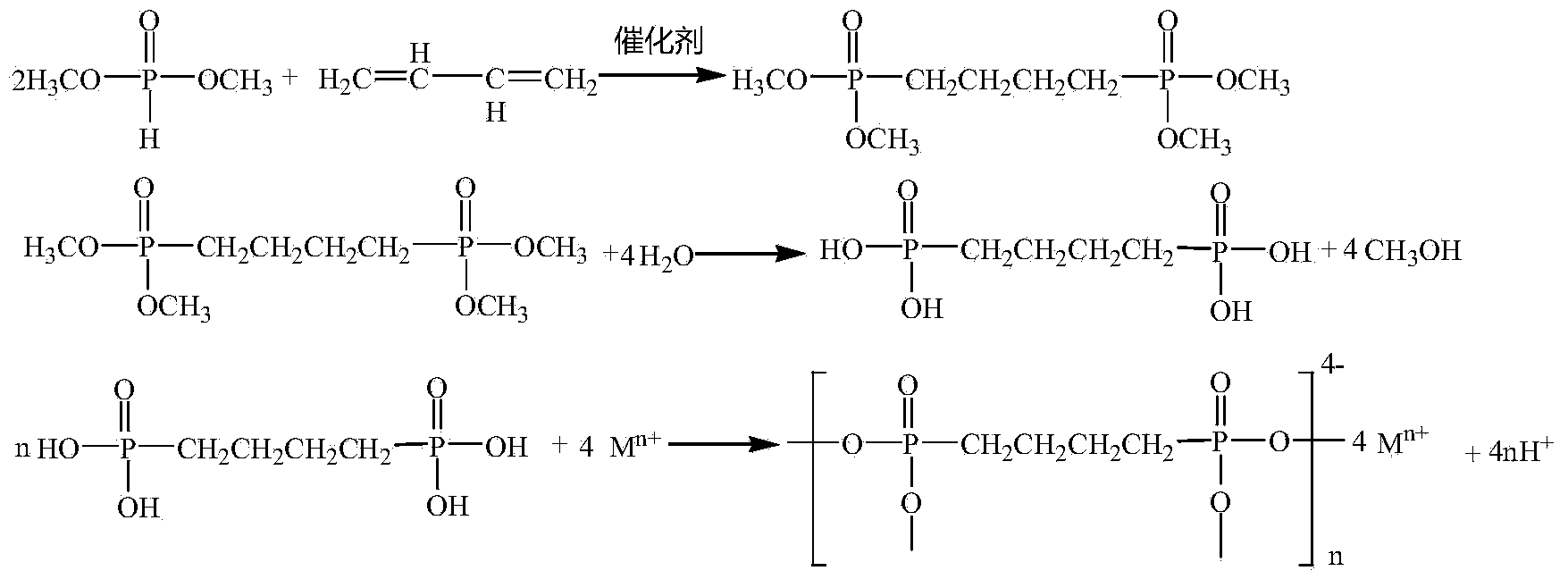

Method used

Image

Examples

Embodiment 1

[0029] Put 3.3Kg dimethyl phosphite into a dry 5L reaction kettle, start stirring, feed acetylene gas, keep the pressure inside the kettle at 0.3MPa, and at the same time add 100g of 30% (mass percent concentration) sodium methoxide solution dropwise, clamp Cooling water is introduced into the jacket to control the temperature in the reactor to be 30-35°C. When the amount of acetylene gas introduced reaches 390g, keep the reaction for 1 hour, and then close the gas source.

[0030] Transfer the material to a hydrolysis kettle, add 2Kg deionized water, raise the temperature to 105°C, and use the reflux rectification method to hydrolyze the methanol. The hydrolyzed product methanol is purified by a rectification tower and recovered for other purposes. After the hydrolysis is completed, the material is cooled and transferred to In the neutralization kettle, the temperature was raised to 75°C, and then 9.4Kg of 40% (mass percent concentration) aluminum sulfate aqueous solution was ...

Embodiment 2

[0034] Put 3.3Kg of dimethyl phosphite into a dry 5L reaction kettle, start stirring, feed 1,3-butadiene gas, keep the pressure in the kettle at 0.4MPa, and drop 30% (mass percent concentration) of Sodium methoxide solution was 100g, and cooling water was passed into the jacket to control the temperature in the reactor to be 35-40°C. When the 1,3-butadiene gas flow rate reached 810g, keep the reaction for 1 hour, and then turn off the gas source. Transfer the material to the hydrolysis kettle, add 2Kg deionized water, raise the temperature to 108°C, and use the reflux rectification methanol method to hydrolyze. The hydrolyzed product methanol is purified by a rectification tower and recovered for other use. After the hydrolysis is completed, the material is cooled and transferred to In the neutralization kettle, the temperature was raised to 85°C, and then 9.4Kg of 40% (mass percent concentration) aluminum sulfate aqueous solution was added dropwise, and a white solid was preci...

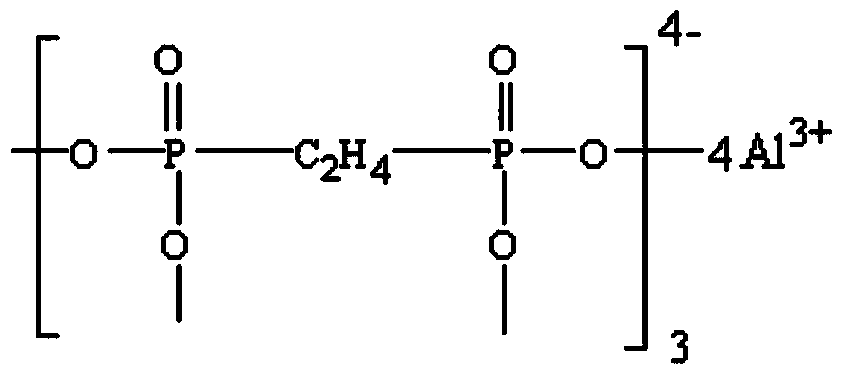

Embodiment 3

[0038] The solution obtained after hydrolysis in Example 1 was transferred to a neutralization kettle, and the temperature was raised to 75°C, and then 9.15Kg of 40% (mass percent concentration) calcium chloride aqueous solution was added dropwise, and a white solid was precipitated, which was filtered, washed with water, After drying, 3918.2 g of organic calcium phosphinate was obtained, with a yield of 98.2%, a purity of 98.8%, and a phosphorus content of 23.17%.

[0039] The product structure formula is:

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com