Binder for lithium ion battery diaphragm, preparation method and diaphragm using the same

A lithium-ion battery and binder technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of poor thermal stability, prone to internal short circuit, etc., achieve high heat resistance, improve thermal stability and Heat shrinkage resistance, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

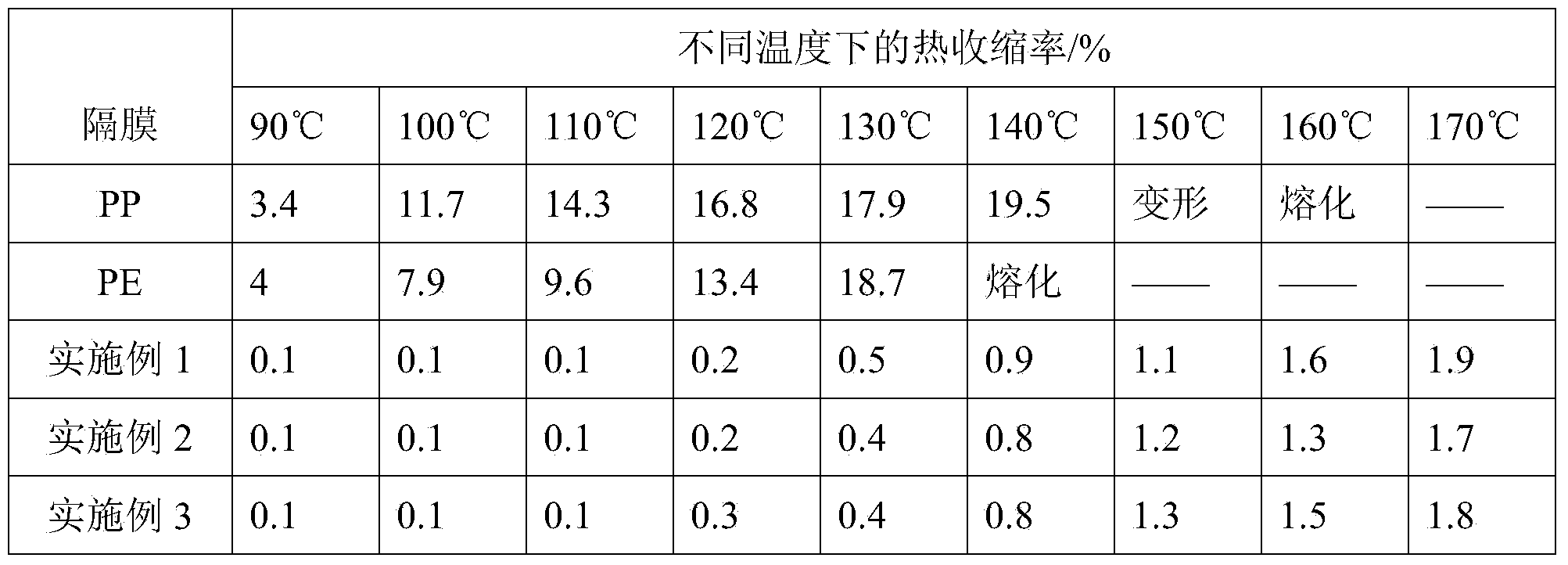

Embodiment 1

[0035] The binder for the lithium-ion battery diaphragm of the present embodiment comprises raw materials of the following weight: polyethylene oxide 1g, acrylonitrile 1g, butylene glycol acrylate 2g, potassium persulfate 0.02g, epoxy butyl oleate 10g, Deionized water 10g.

[0036] The preparation method of the binder for the lithium-ion battery separator of the present embodiment comprises the following steps:

[0037] 1) Take 1g of polyethylene oxide and place it in 10g of deionized water, raise the temperature to 100°C, stir to dissolve it completely, and obtain solution A;

[0038] 2) After the solution A obtained in step 1) cools down, take 1g of acrylonitrile (hard segment monomer) and 2g of butylene glycol acrylate (soft segment monomer) and add them to solution A in sequence, and then, under the protection of nitrogen, Add 0.02g of potassium persulfate to initiate polymerization, and stir at 100°C to carry out the polymerization reaction. The reaction time is 6 hours, a...

Embodiment 2

[0047] The binder for lithium-ion battery separator of the present embodiment comprises the raw material of following weight: polyvinyl alcohol 1g, acrylonitrile 1g, diethylene glycol methyl ether methacrylate 2g, ammonium persulfate 0.01g, triethyl phosphate 10g, deionized water 10g.

[0048] The preparation method of the binder for the lithium-ion battery separator of the present embodiment comprises the following steps:

[0049] 1) Take 1g of polyvinyl alcohol and place it in 10g of deionized water, raise the temperature to 70°C, stir to dissolve it completely, and obtain solution A;

[0050] 2) After the solution A obtained in step 1) cools down, add 1g of acrylonitrile (hard segment monomer) and 2g of diethylene glycol methyl ether methacrylate (soft segment monomer) into solution A in sequence, Under the protection of nitrogen, add 0.01g of ammonium persulfate to initiate polymerization, and stir at 70°C to carry out the polymerization reaction. The reaction time is 10 ...

Embodiment 3

[0059] The binder for lithium-ion battery separator of the present embodiment comprises the raw material of following weight: polyvinylpyrrolidone 0.5g, vinyl acetate 2g, styrene 1g, potassium persulfate 0.01g, diethylene glycol benzoic acid 10g of ester, 10g of deionized water.

[0060] The preparation method of the binder for the lithium-ion battery separator of the present embodiment comprises the following steps:

[0061] 1) Take 1g of polyvinylpyrrolidone and place it in 10g of deionized water, raise the temperature to 90°C, stir to dissolve it completely, and obtain solution A;

[0062] 2) After the solution A obtained in step 1) cools down, add 2g of vinyl acetate (soft segment monomer) and 1g of styrene (rigid segment monomer) to solution A in sequence, and then add 0.01g of potassium persulfate initiates polymerization, and under the condition of 70°C, the polymerization reaction is carried out with stirring, the reaction time is 10h, and a white emulsion is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com