Preparation method of SAPO-34 molecular sieve membrane

A technology of SAPO-34 and molecular sieve, applied in the field of preparation of SAPO-34 molecular sieve membrane, can solve the problems of inability to detect membrane tubes well, high price, restricting membrane engineering application, etc., to shorten synthesis time, improve quality, The effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

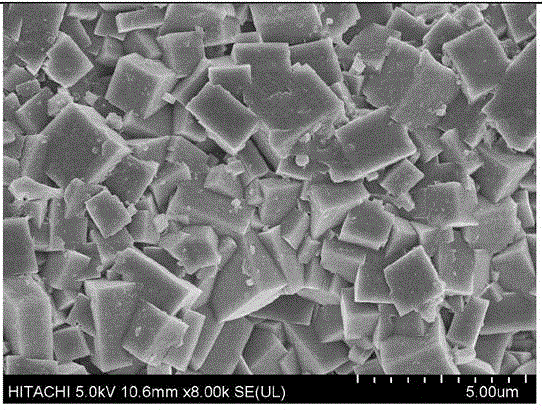

[0030] (1) Preparation of SAPO-34 seed crystals: mix the template agent tetraethylammonium hydroxide for short TEAOH, aluminum n-butoxide, phosphoric acid, silicon source chabazite and water, and after aging for 1 hour at room temperature, the formed sol The molar ratio of the components is: P 2 o 5 / Al 2 o 3 = 0.7, SiO 2 / Al 2 o 3 =0.5, TEAOH / Al 2 o 3 =1.8,H 2 O / Al 2 o 3 =70. The sol was added into a polytetrafluoroethylene-lined stainless steel reactor, hydrothermally synthesized at a synthesis temperature of 190° C. for 2 hours, and cleaned by centrifugation to obtain a SAPO-34 molecular sieve.

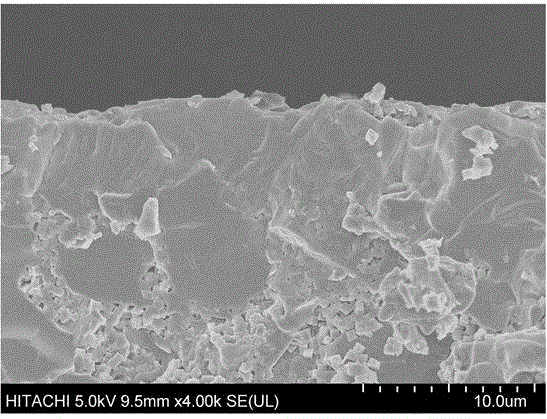

[0031] (2) Support body pretreatment: Porous mullite tube is used as the support body for membrane synthesis, and the molar ratio is 66% Al 2 o 3 and 34% SiO 2 . The inner and outer diameters are 9mm and 12mm respectively, the length is 100mm, the average pore diameter is about 1.0μm, and the porosity is about 30%. The outer wall of the support body was pretreated w...

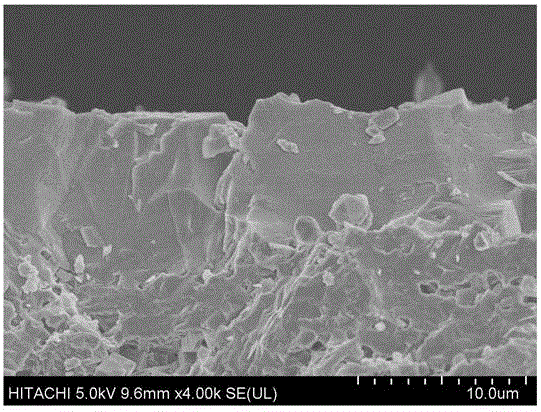

Embodiment 2

[0039] (1) Preparation of seed crystals: the preparation process is the same as step (1) in Example 1, except that aluminum foil is selected as the aluminum source, and the molar ratio of the sol is P 2 o 5 / Al 2 o 3 = 0.9, SiO 2 / Al 2 o 3 =0.05, TEAOH / Al 2 o 3 = 1.5, H 2 O / Al 2 o 3 =40.

[0040] (2) Support body pretreatment: the preparation process is the same as step (2) of Example 1, except that the seed crystal content in the seed crystal suspension is 2% of the solution mass, and the pH value is adjusted to 10 by using sodium hydroxide aqueous solution.

[0041] (3) Synthesis of SAPO-34 molecular sieve membrane: the preparation process is the same as step (3) of Example 1, except that aluminum powder is selected as the aluminum source.

[0042] The prepared membrane M2 was used at 25°C, CO 2 / CH 4 The gas separation performance was characterized in the (50 / 50) system, and the results of the gas separation experiment are shown in Table 1.

Embodiment 3

[0044] (1) Preparation of seed crystals: the preparation process is the same as step (1) of Example 1, except that aluminum hydroxide is selected as the aluminum source, and the sol is aged at room temperature for 12 hours.

[0045] (2) support body pretreatment: the preparation process is the same as step (2) of embodiment 1, the difference is that the 5% polydiallyldimethylamine sulfate solution whose mass concentration is the total mass of the solution is used, and the immersion time is 0.5 Hour.

[0046] (3) Synthesis of SAPO-34 molecular sieve membrane: the preparation process is the same as step (3) in Example 1, except that aluminum isopropoxide is selected as the aluminum source.

[0047] The prepared membrane M3 was used at 25°C, CO 2 / CH 4 The gas separation performance was characterized in the (50 / 50) system, and the results of the gas separation experiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com