Slow release type feed acidifying agent preparing method

A feed acidifier, slow-release technology, applied in animal feed, animal feed, application, etc., can solve the problems of equipment corrosion, low active ingredient, easy to corrode the skin of production workers, etc., to reduce production energy consumption and product cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

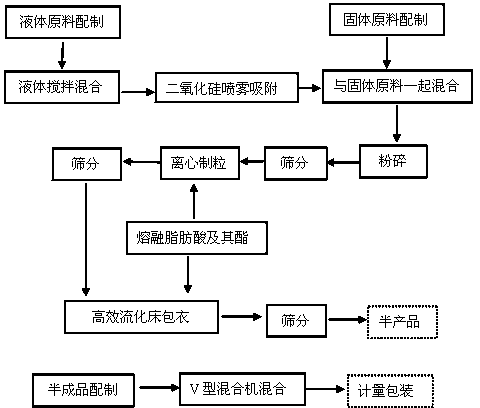

[0037] The preparation method of the slow-release feed acidifier of the present invention, the specific preparation process is as follows, you can also refer to figure 1 ,

[0038] 1) Prepare a packaging material with a certain release rate;

[0039] 1.1) Prepare materials according to the following mass parts: liquid acid 0-25; silicon dioxide 0-10; solid acid 30-60; fatty acid and its ester 15-40; (fatty acid and its ester are the collective name of fatty acid and fatty acid ester, Among the two, fatty acids account for 20-80%, and fatty acid esters account for 80-20%)

[0040] 1.2) The liquid acid in the raw material is adsorbed by silica and mixed evenly with all the solid acids to obtain the mixed material;

[0041] 1.3) After the mixed material is pulverized by a pulverizer, it reaches below 80 mesh to obtain a powder material;

[0042] 1.4) Heat the fatty acid and its ester to 100-105°C to make it in a molten state;

[0043] 1.5) Divide the powder material obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com