Abscisic acid receptor stimulant raw drug and preparation method thereof

An abscisic acid receptor and agonist technology, applied in the preparation of sulfonic acid, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of high production cost, achieve the effects of low cost, high activity, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

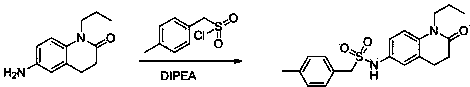

Image

Examples

Embodiment 1

[0040] An original drug of an abscisic acid receptor agonist, the raw materials in molar parts include: 1 part of quinolinone, 4.5 parts of sodium hydride, 5 parts of iodopropane, 40 parts of fuming nitric acid, 1.5 parts of hydrochloric acid, 4.5 parts of iron powder, 1-2 parts, 1.2 parts of thiourea, 1.2 parts of acid-binding agent potassium carbonate, 5 parts of sodium perchlorate, 6 parts of concentrated hydrochloric acid, 1.4 parts of N,N-diisopropylethylamine.

[0041] The preparation method of the former medicine of described abscisic acid receptor agonist comprises the steps:

[0042] (1) Weighing raw materials: Weighing each raw material according to mole fraction;

[0043](2) Preparation of N-propyl quinolinone: A. Add quinolinone into the organic solvent N,N-dimethylformamide, stir at -6°C for 0.5h; B. Separate under argon protection environment Add sodium hydride in batches as a catalyst, and stir for 0.5 hours after the addition; C. Add halopropane dropwise into...

Embodiment 2

[0057] An original drug of an abscisic acid receptor agonist, the raw materials in molar parts include: 1.5 parts of quinolinone, 5 parts of sodium hydride, 7 parts of iodopropane, 45 parts of fuming nitric acid, 3 parts of hydrochloric acid, 5 parts of iron powder, 2 parts, 1.5 parts of thiourea, 1.8 parts of acid-binding agent potassium carbonate, 6 parts of sodium perchlorate, 15 parts of concentrated hydrochloric acid, and 1.5 parts of N,N-diisopropylethylamine.

[0058] The preparation method of the former medicine of described abscisic acid receptor agonist comprises the steps:

[0059] (1) Weighing raw materials: Weighing each raw material according to mole fraction;

[0060] (2) Preparation of N-propyl quinolinone: A. Add quinolinone into the organic solvent N,N-dimethylformamide, and stir at -5°C for 0.8h; B. Separate under argon protection environment Add sodium hydride in batches as a catalyst, and stir for 0.8 hours after the addition; C, drop iodopropane into th...

Embodiment 3

[0074] An original drug of an abscisic acid receptor agonist. The raw materials in molar parts include: 2 parts of quinolinone, 5.5 parts of sodium hydride, 10 parts of iodopropane, 50 parts of fuming nitric acid, 5.5 parts of hydrochloric acid, 5.5 parts of iron powder, 1 part, 1.5 parts of potassium thioacetate, 1.5 parts of acid-binding agent potassium carbonate, and 1.6 parts of N,N-diisopropylethylamine.

[0075] The preparation method of the former medicine of described abscisic acid receptor agonist comprises the steps:

[0076] (1) Weighing raw materials: Weighing each raw material according to mole fraction;

[0077] (2) Preparation of N-propyl quinolinone: A. Add quinolinone into the organic solvent N,N-dimethylformamide, and stir at -4°C for 1 hour; B. Batch under the protection of argon Add sodium hydride as a catalyst, and stir for 1 hour after the addition; C, add iodopropane dropwise into the solution, and react at room temperature for 13 hours; D, add water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com