Making method of platinum iridium oxide alloy electrode

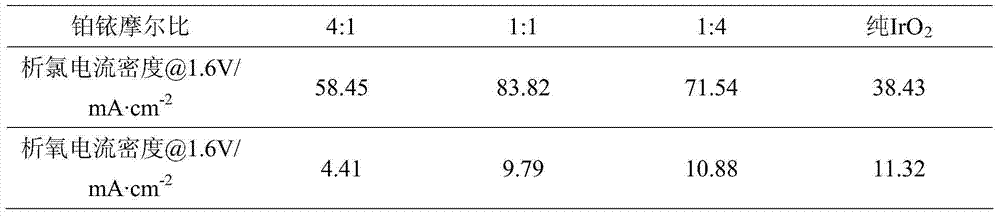

A technology of alloy electrodes and oxides, which is applied in the direction of electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of co-solubility price difference, failure to meet the service life requirements of electrode materials, and no report on the performance of oxidized electrolyzed water, etc., to achieve chlorine analysis. High catalytic activity, low cost of use, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

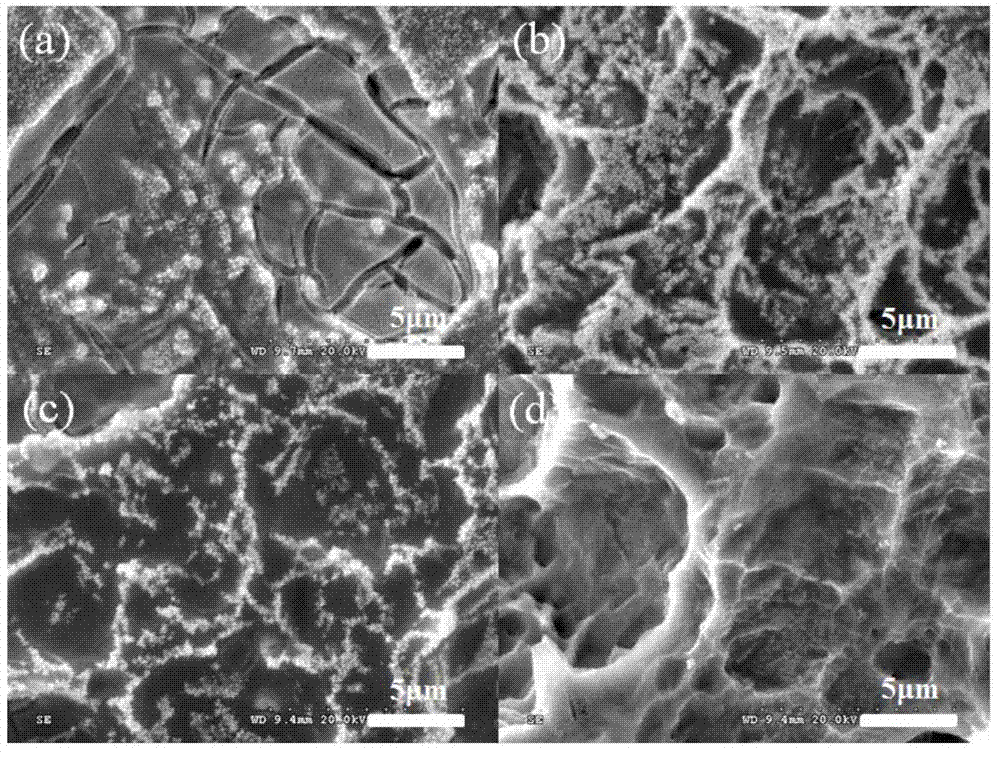

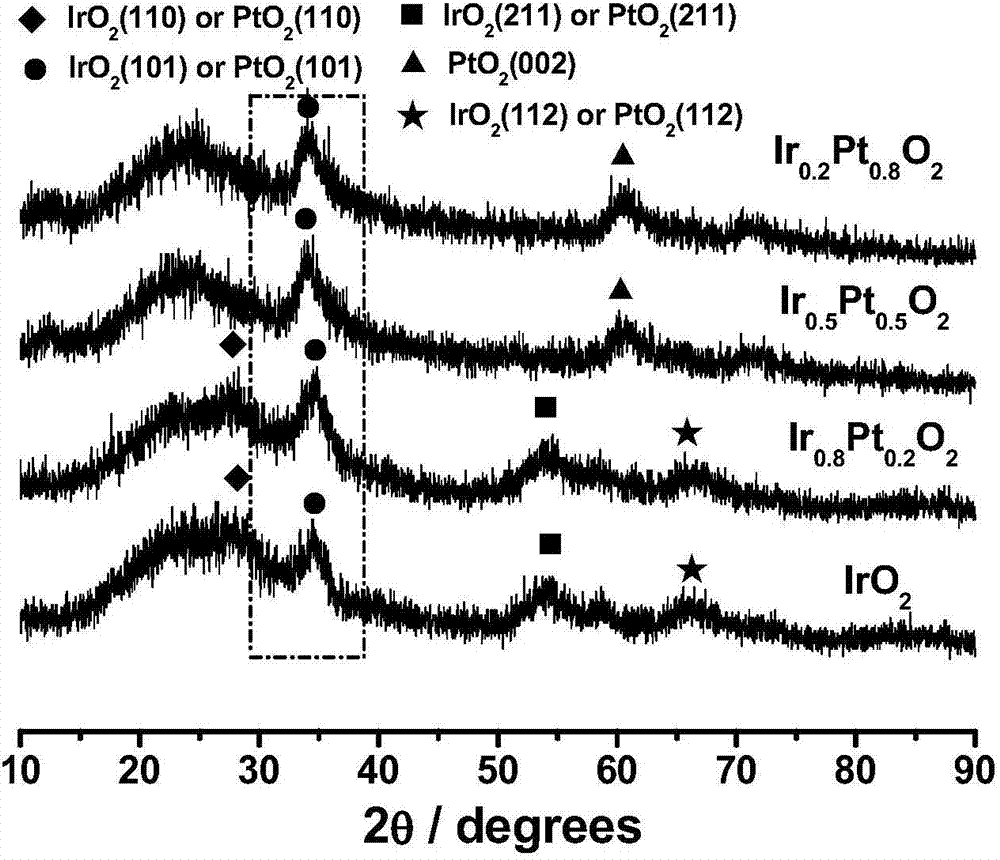

[0024] The preparation process of the titanium-based platinum-iridium oxide alloy electrode of the present invention is as follows:

[0025] (1) Pretreatment of titanium substrate: sandblasting, degreasing, ultrasonic acid etching, cleaning, drying;

[0026] (2) Preparation of platinum dioxide: heat and stir the mixed solution of platinum salt and sodium nitrate at 55-65°C, evaporate and crystallize, dry, grind, and roast to obtain the mixture, then carry out sufficient wet grinding, and disperse in the solvent to obtain platinum dioxide Platinum solution; the metal ion concentration of platinum salt is 0.05-0.3mol L -1 , adding sodium nitrate concentration is 0.4-2.4mol L -1 ; The sintering process is sintering at 500° C. for 30 minutes.

[0027] (3) Configuration of the coating solution: disperse the iridium salt into the solvent, and then add the above-mentioned platinum dioxide solution so that the metal ion concentration is 0.05-0.3mol L -1 , and then adjust the pH val...

Embodiment 1

[0035] A 10cm×5cm TA1 titanium plate was first sandblasted, then washed with 10% sodium carbonate solution for 10 minutes under the action of ultrasonic waves to remove oil, then washed with deionized water under the action of ultrasonic waves, and then washed with 10wt% oxalic acid Activated at 96°C for 40min, finally rinsed with deionized water, dried in the air, and stored in absolute ethanol.

[0036] 2.590g H 2 PtCl 6 Dissolve in 50 mL of ethanol and isopropanol solvent with a volume ratio of 1:1, so that the concentration of metal ions in the solution is 0.1 mol L -1 , stir well. Then add 3.400 g of solid sodium nitrate to the solution, stir and heat to 60° C., and keep stirring until the solvent evaporates completely. The mixture was then completely dried in an oven at 80°C to obtain a dry salt mixture, which was thoroughly ground in an agate mortar to make it evenly mixed. Then bake in a tube furnace at 500 °C for 30 min with a heating rate of 5 °C min -1 , to obt...

Embodiment 2

[0050] A 10cm×5cm TA1 titanium plate was first sandblasted, then washed with 10% sodium carbonate solution for 10 minutes under the action of ultrasonic waves to remove oil, then washed with deionized water under the action of ultrasonic waves, and then washed with 10wt% oxalic acid Activated at 96°C for 40min, finally rinsed with deionized water, dried in the air, and stored in absolute ethanol.

[0051] 2.590g H 2 PtCl 6 Dissolve in 50 mL of ethanol and isopropanol solvent with a volume ratio of 1:1, so that the concentration of metal ions in the solution is 0.1 mol L -1 , stir well. Then add 3.400 g of solid sodium nitrate to the solution, stir and heat to 60° C., and keep stirring until the solvent evaporates completely. The mixture was then completely dried in an oven at 80°C to obtain a dry salt mixture, which was thoroughly ground in an agate mortar to make it evenly mixed. Then bake in a tube furnace at 500 °C for 30 min with a heating rate of 5 °C min -1 , to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent area | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com