High-transparency composite thin film capable of adsorbing ultraviolet rays and preparation method thereof

A composite film and ultraviolet technology, which is applied in the direction of radiation-absorbing coatings, coatings, anti-corrosion coatings, etc., can solve the problems of reducing the service life of the base material, the impact of service life, and the degradation of the base material, achieving ultra-long weather resistance and improving properties , the effect of ingredient science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

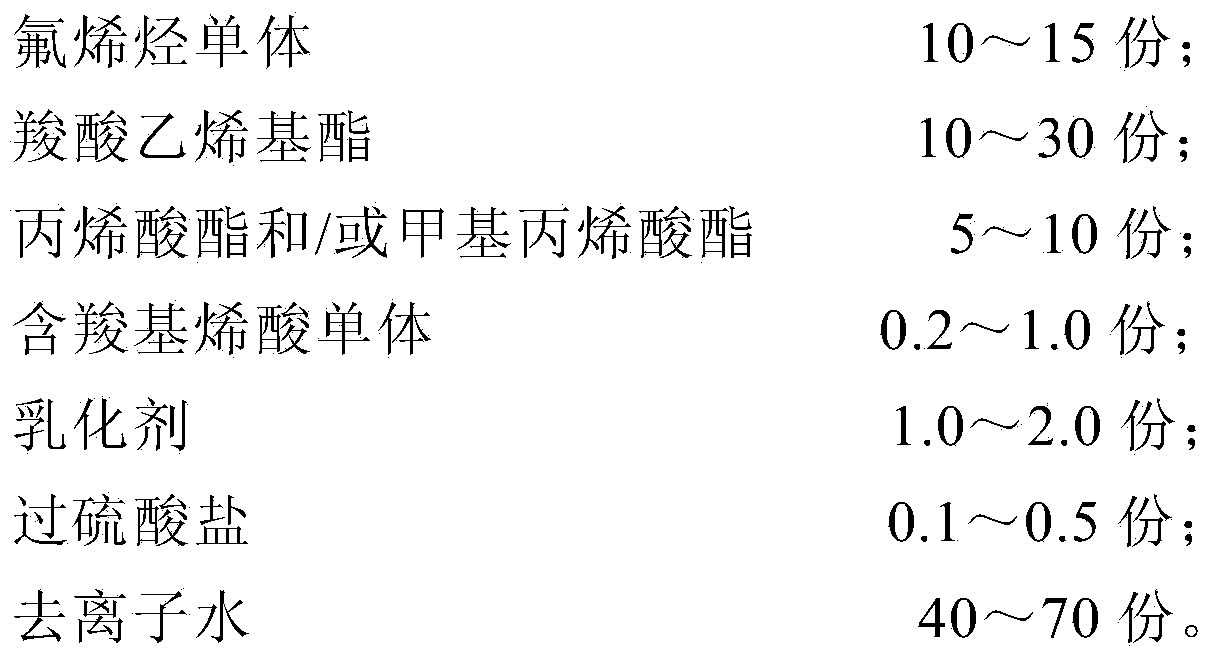

[0025] This embodiment discloses an aqueous dispersion of fluoropolymers, comprising the following components by weight ratio: 86.00 g of chlorotrifluoroethylene, 142.00 g of vinyl acetate, 47.00 g of vinyl tertiary carbonate (VeoVa10), 47.00 g of acrylic acid Butyl ester 47.00g, acrylic acid 4.00g, ionic emulsifier sodium lauryl sulfate 1.20g, nonionic emulsifier nonylphenol polyoxyethylene ether 5.62g and styrylphenol polyoxyethylene ether 5.22g, Potassium persulfate 1.67g, deionized water 380.00g.

[0026] The preparation method of the aqueous fluoropolymer dispersion in this example is as follows: In a 1L autoclave, add 1.20 g of sodium lauryl sulfate, 5.62 g of nonylphenol polyoxyethylene ether, styrylphenol polyoxyethylene 5.22g of ether, 380.00g of deionized water, 142.00g of vinyl acetate, 47.00g of vinyl tert-carbonate (VeoVa10), 47.00g of butyl acrylate, and 4.00g of acrylic acid were added in sequence, vacuumized and filled with nitrogen, after repeated 3 times , a...

Embodiment 2

[0029] This embodiment discloses a high-transparency composite film that can absorb ultraviolet rays and is used in the field of thin film packaging of electronic devices. It is formed by spin coating raw materials, and the raw materials include: fluoropolymer aqueous dispersion, 2,2,4- Trimethyl-1,3-pentanediol monoisobutyrate (alcohol ester dodeca) and zinc acetate dihydrate. The mass ratio of each component in the raw material is shown in Table 1, wherein the aqueous fluoropolymer dispersion is the aqueous fluoropolymer dispersion prepared in Example 1.

[0030] Specifically, the preparation steps of the ultraviolet-absorbable and highly transparent composite film are as follows: put 10 g of the aqueous fluoropolymer dispersion prepared in Example 1 into a 50 ml beaker, add 0.25 g of alcohol ester twelve, disperse for 30 minutes, add 1.15 g of zinc acetate dihydrate was dispersed by magnetic stirring for 30 minutes to prepare a zinc salt-containing fluoropolymer composite a...

Embodiment 3

[0032] This embodiment discloses a high-transparency composite film that can absorb ultraviolet rays and is used in the fields of thin film packaging of electronic devices. The aqueous fluoropolymer dispersion prepared in Example 1.

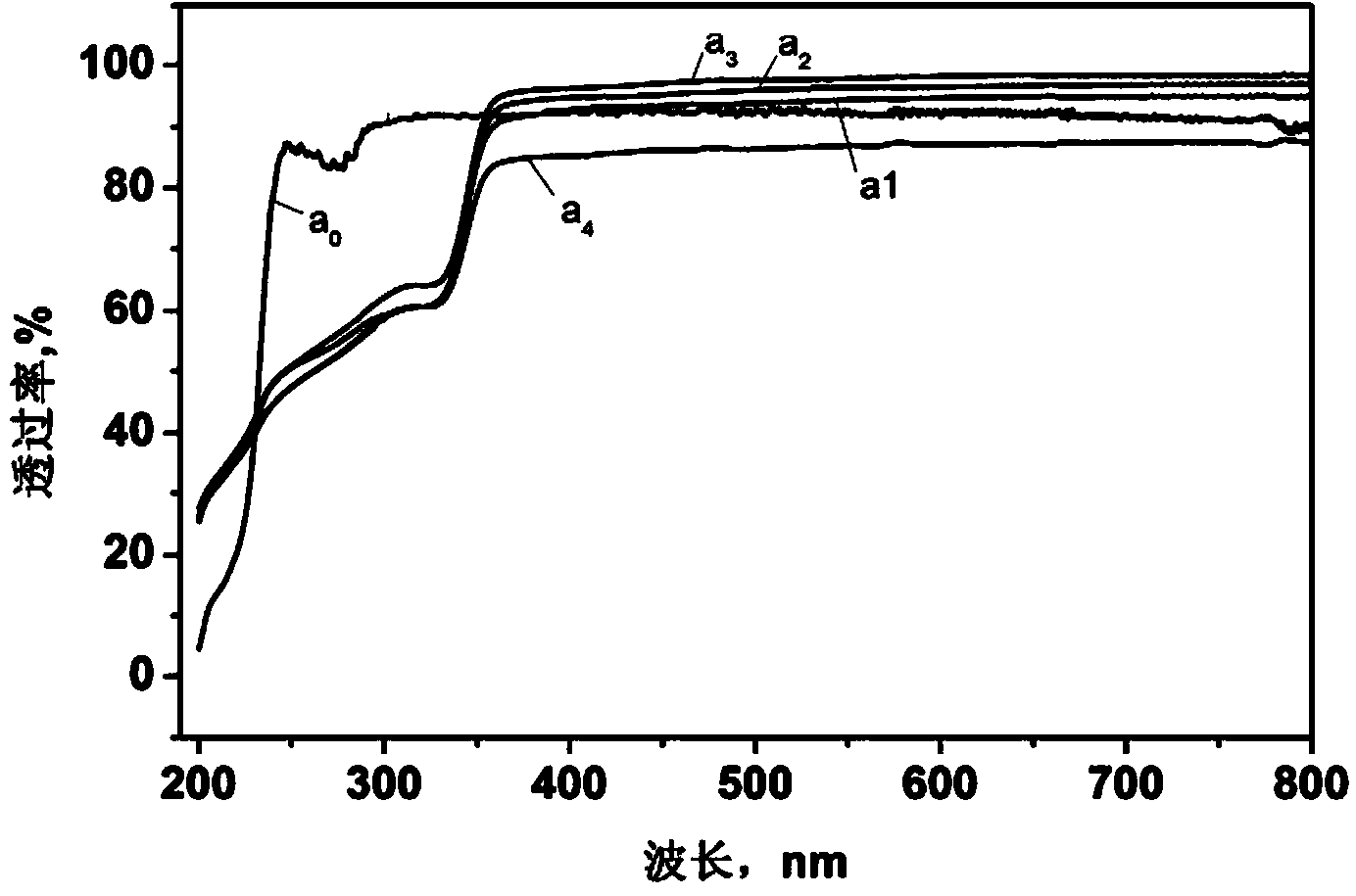

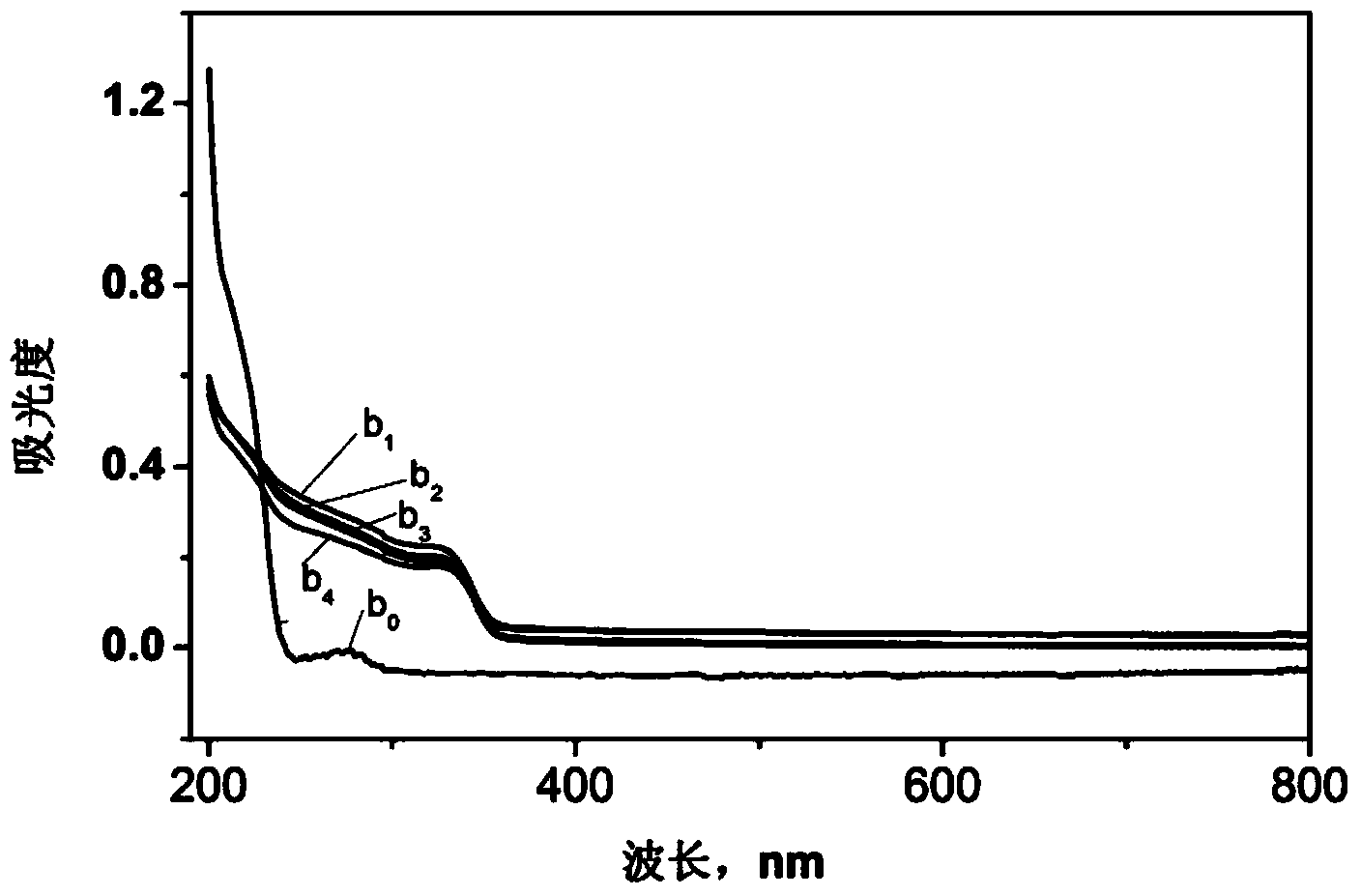

[0033] The preparation steps of the ultraviolet-absorbing and highly transparent composite film in this embodiment are the same as those in Embodiment 2. The transmission and absorption spectra of the prepared ultraviolet-absorbing and highly transparent composite film are shown in figure 1 (a 2 curve) and figure 2 (b 2 curve).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com