Sludge pyrolysis and gasification treatment process and sludge pyrolysis and gasification treatment system

A technology of pyrolysis gasification and treatment system, applied in the field of sludge treatment, can solve the problems of large floor space, low organic matter content, difficult to popularize and popularize, etc., to reduce investment cost and production cost, simple treatment process, Highly intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

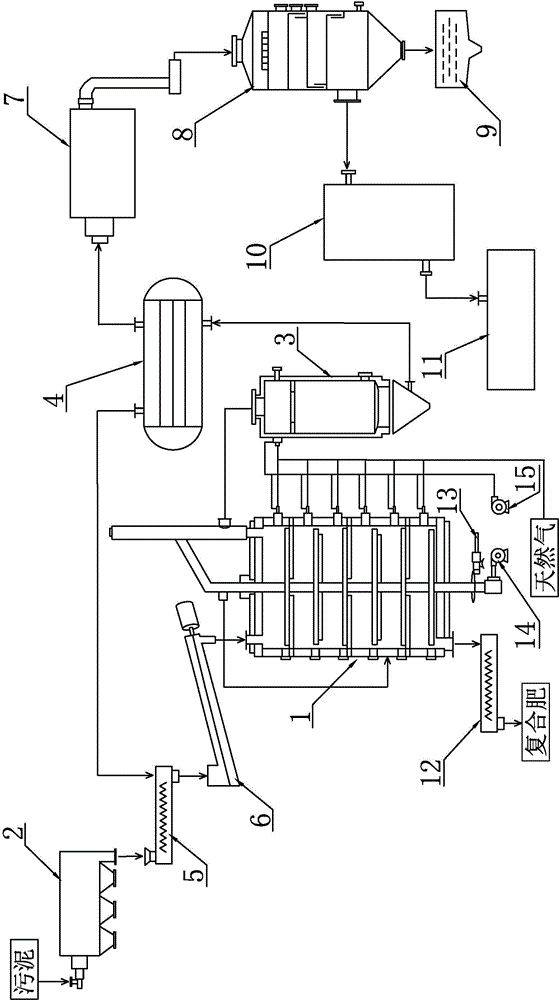

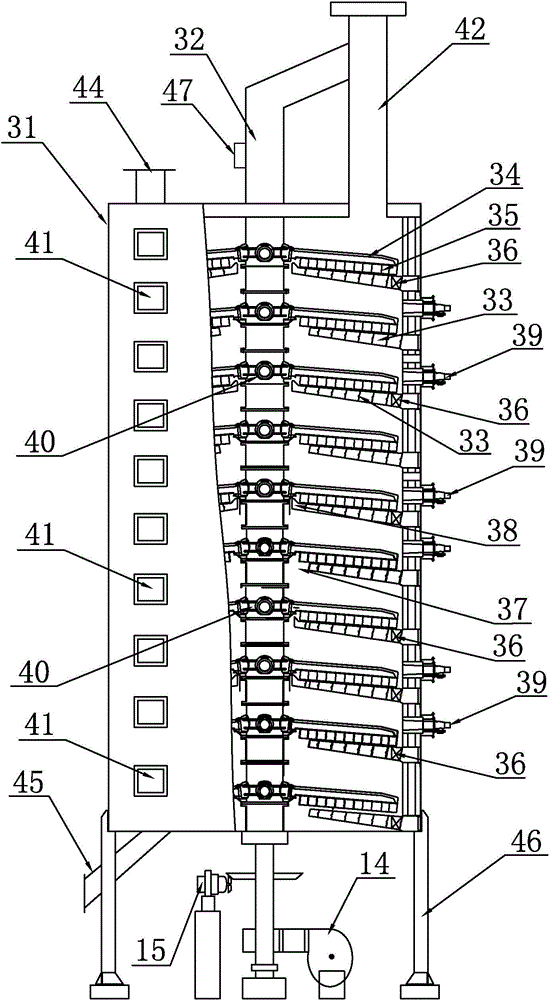

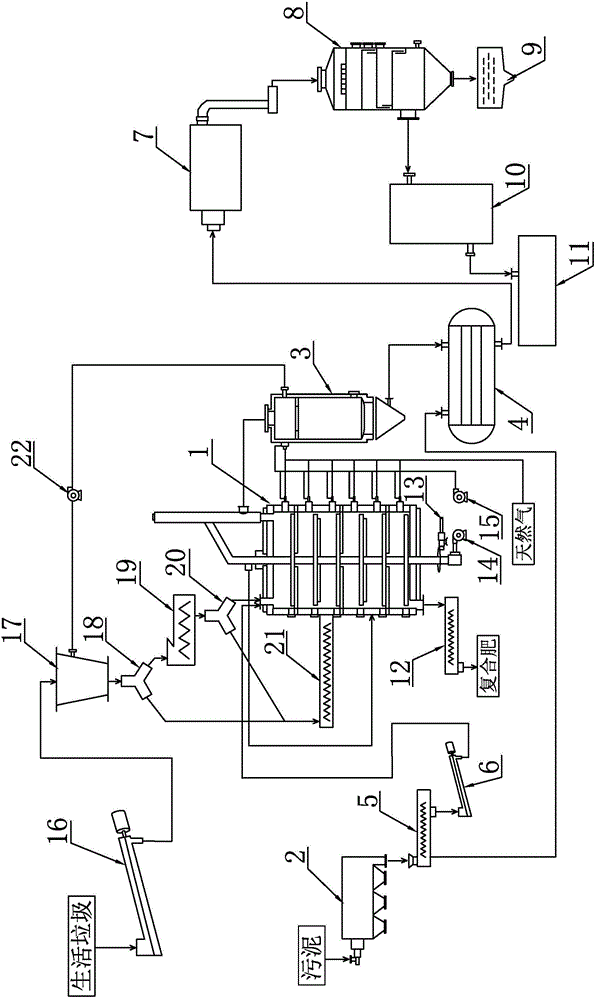

[0027] like figure 1 Shown is a schematic structural diagram of sludge pyrolysis by a sludge pyrolysis gasification treatment system of the present invention, including a multi-stage furnace 1, a sludge dehydrator 2, a waste heat boiler 4, a post-combustion chamber 3, a scrubber 8 and Gas Generator 11. The discharge port of the sludge dehydrator 2 is connected to the feed port of the first screw feeder 5, the discharge port of the first screw feeder 5 is connected to the feed port of the scraper conveyor 6, and the scraper conveyor 6 The discharge port of the multi-stage furnace is connected to the material inlet 44 at the top of the multi-stage furnace 1 through a conveying pipeline, and the dehydrated sludge is fully pyrolyzed in the multi-stage furnace 1, and the solid product after pyrolysis passes through the slag discharge pipe 45 at the bottom of the multi-stage furnace 1 Discharge, the slag discharge pipeline 45 at the bottom of the multi-stage furnace 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com