Preparation method and application of TiO2-SiO2 composite nanofiber supported amorphous alloy catalyst

A composite nanofiber, amorphous alloy technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of easy agglomeration and poor catalyst stability , low catalytic activity of the catalyst, etc., to achieve the effect of reducing the preparation cost, low price and overcoming the expensive price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] TiO 2 -SiO 2 Composite nanofiber supported CoB amorphous alloy catalyst:

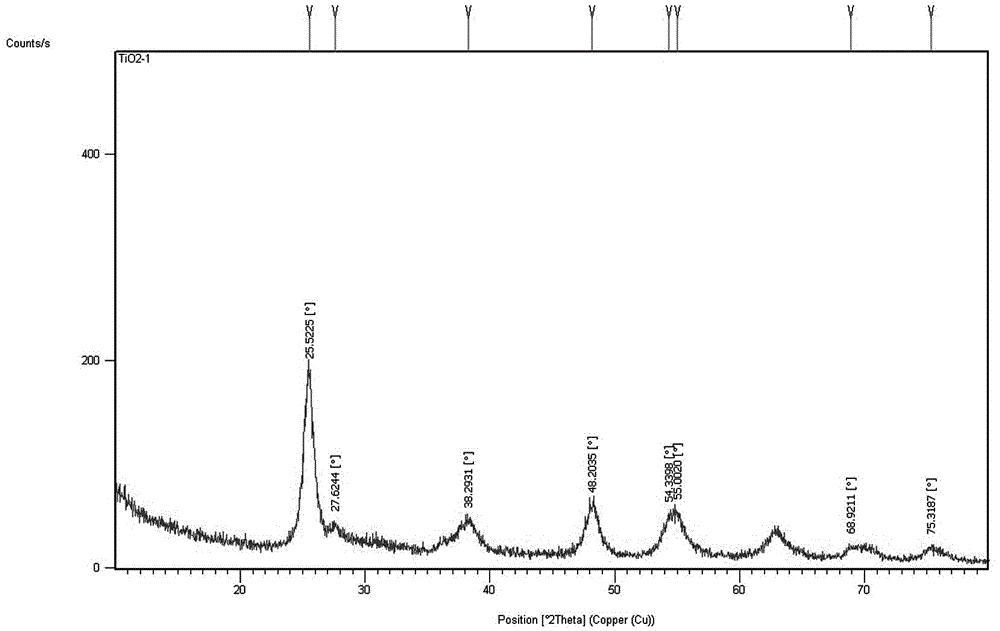

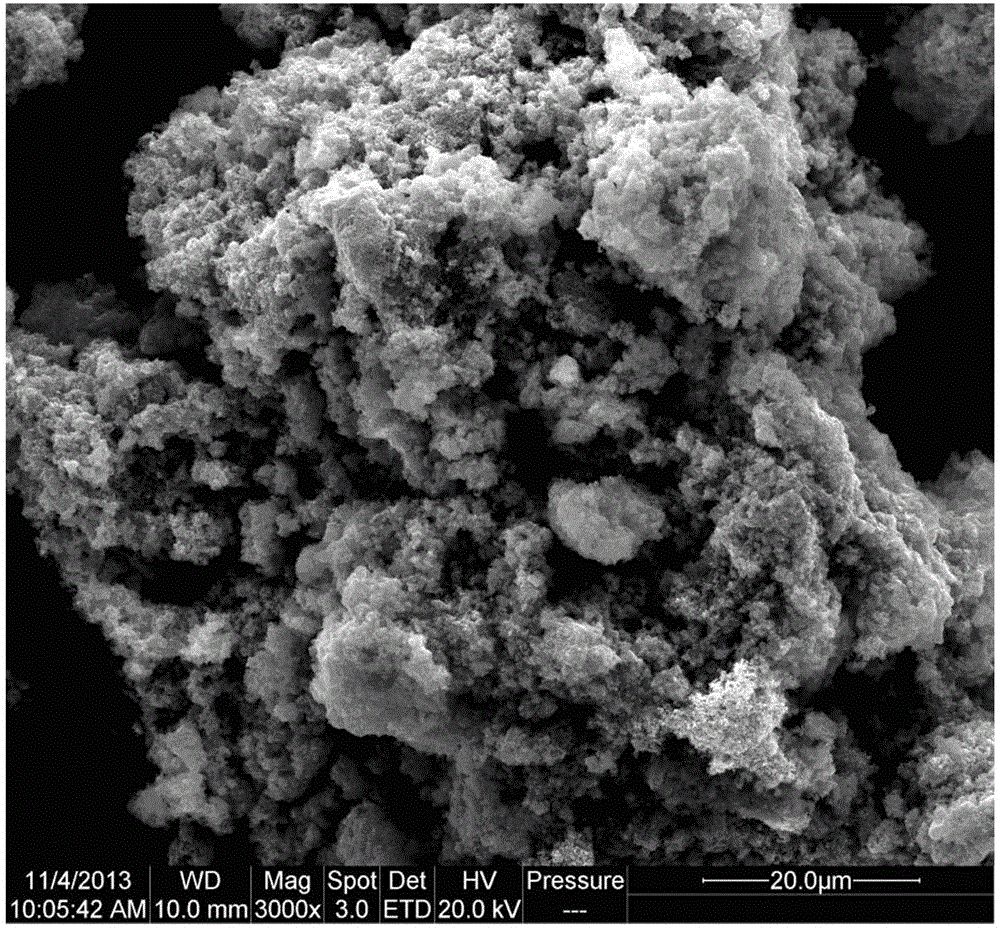

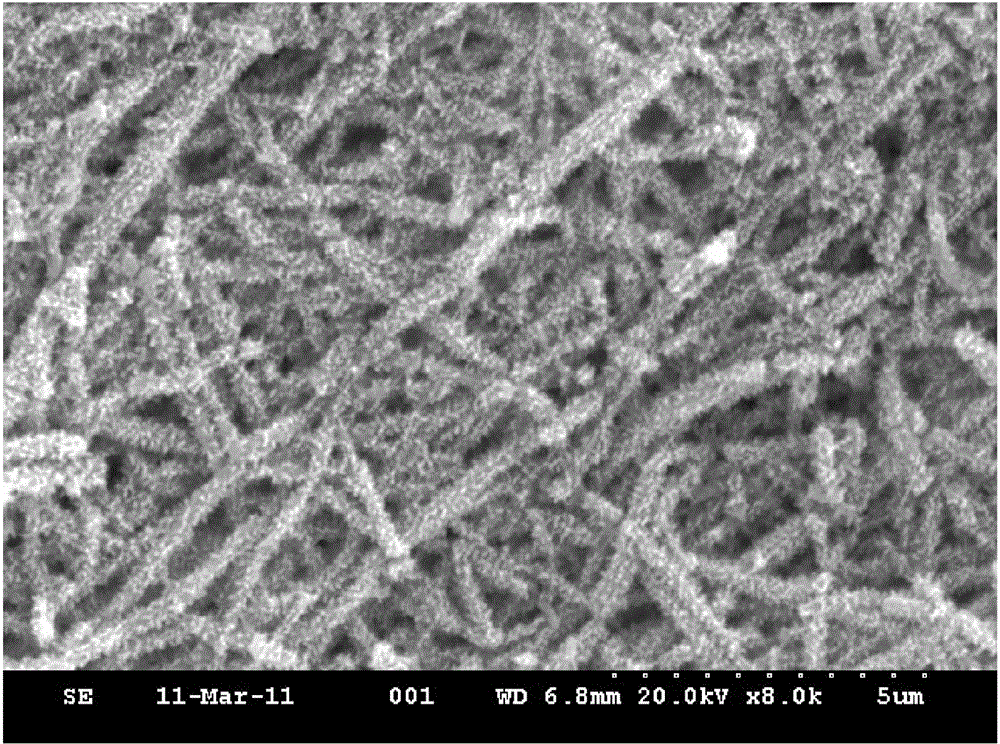

[0036] Using tetraethyl orthosilicate and tetrabutyl titanate as raw materials, DMF (N, N-dimethylformamide) as solvent, and PVP (polyvinylpyrrolidone) as polymer to prepare TiO 2 -SiO 2 composite nanofibers. Weigh 2.557g of tetrabutyl titanate and 0.52g of tetraethyl orthosilicate, mix and stir to obtain a transparent and uniform solution. Next, 0.8 g of PVP and 8 g of DMF were weighed and mixed and stirred until the PVP was completely dissolved to obtain another mixed solution, and then the above two mixed solutions were mixed as a precursor solution for electrospinning. The precursor solution was prepared by electrospinning to prepare the nanofiber precursor. The electrospinning process conditions are as follows: the voltage is 18kV, the speed of the receiving cylinder is 600r / min, and the distance between the nozzle and the receiving cylinder is 15cm. Nanofiber precursors obtained by ele...

Embodiment 2

[0040] Take a certain amount of TiO 2 -SiO 2 Composite nanofibers in a forced air oven at 150 o C drying 3h standby. Weigh 0.51g CoCl 2 .6H 2 O is placed in a small beaker, then measure 30ml of water to dissolve. 3g dried TiO 2 -SiO 2 Composite nanofiber powder added to CoCl 2 solution, dipping, magnetic stirring for 3h. The stirred solution was vacuum-dried at room temperature in a vacuum box to obtain a blue solid. Weigh 0.33g NaBH 4 In a small beaker, first pour 10ml of ethanol, and then pour 10ml of water to dissolve completely. Place the obtained blue solid in a two-necked round bottom flask under N 2 Protected with the above NaBH 4 Titration. The titrated solution is suction filtered, washed, and vacuum-dried to obtain TiO 2 -SiO 2 Composite nanofiber-supported CoB amorphous alloy catalyst, the obtained solid characteristics are similar to Example 1.

[0041] Weigh the catalyst with the same CoB content and the same ratio of NaBH in Example 1 4 The powde...

Embodiment 3

[0043] Weigh a certain amount of TiO 2 -SiO 2 Composite nanofibers in a forced air oven at 150 o C drying 3h standby. Weigh 0.816g CoCl 2 .6H 2 O was dissolved in 30ml of water, and 3g of dried TiO 2 -SiO 2 The composite nanofiber powder is poured in, impregnated and stirred for 3 hours. The stirred solution was vacuum-dried at room temperature in a vacuum box to obtain a blue solid. Weigh 0.27g NaBH 4 Dissolved in a mixed solution of ethanol and water (15ml C 2 h 5 OH+15ml H 2 O). Put the above blue solid in a two-necked round bottom flask, and use the above prepared NaBH 4 solution in N 2 Titration was performed under protection. The titrated solution is suction filtered, washed, and vacuum-dried to obtain a solid that is TiO 2 -SiO 2 Composite nanofibers supported CoB amorphous alloy catalysts, and the properties of the finished products were similar to those described above.

[0044] Under the same reaction conditions with NaBH 4 The reaction speeds up. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com